100% Forecasting Error Reduction and Up to $300M Saving Potential for a Global High-Tech Hardware Leader

Challenges

A global company manufacturing high-performance computing hardware systems needs accurate demand forecasting to optimize production and inventory levels, reduce operation costs, enhance customer service, and strengthen supply chain resilience. Much of its business is made-to-order with volatile demand, making forecasting challenging.

Historically, the company struggled to forecast demand due to irregular sales patterns and limited historical data for its customized products. Demand planners manually gathered feedback from sales teams and applied their judgment to create demand forecasts, frequently leading to inaccurate results.

The company initially attempted to use a market-leading forecasting solution to improve its forecast accuracy. However, the solution presented various limitations:

- Reliance on aggregated sales data to forecast led to the loss of valuable demand signals in order-level data.

- The one-size-fits-all AI approach was unfit for highly volatile demand, made-to-order SKUs.

- The data science approach was not robust enough to forecast demand in new product introduction situations (new SKUs with limited historical data).

- Inadequate ML model management and operations tools decreased forecast accuracy over time.

- The generated forecasts lacked explainability, leading to user distrust, low adoption, and manual overwriting of model forecasts.

Because of these limitations, this solution produced poor forecast accuracy with weighted absolute percentage errors (WAPE) — a common measure of forecast errors — of over 200%. In fact, this commercial solution was less accurate than the company’s own consensus forecast.

The customer then asked C3 AI to deploy C3 AI Demand Planning to improve its forecasting accuracy.

Approach

C3 AI initially configured the C3 AI Demand Planning application for the High-Performance Computing (HPC) division across 900 SKUs. This business segment averaged $4B+ in annual sales.

C3 AI Demand Planning reduced forecast errors, WAPE, by 70 – 100% compared to baseline forecasts, enabling a 7% potential inventory reduction and $300M company-wide savings. After proving the value with one division, C3 AI is scaling the solution to the entire company.

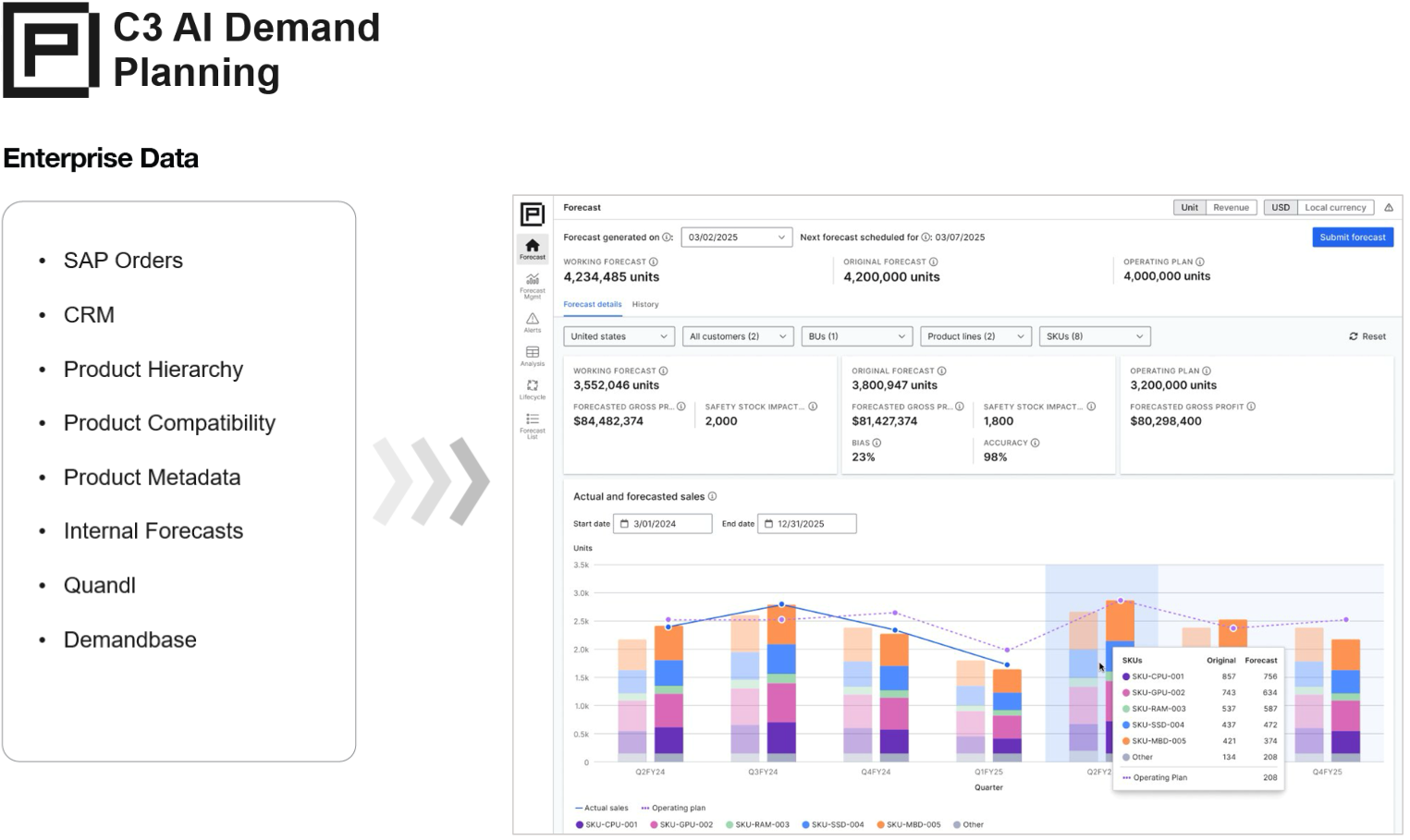

To achieve these results, the C3 AI team first leveraged the Supply Chain Digital Twin to unify and ingest three years of historical orders, CRM, and product data (20+ million rows across six enterprise systems), providing the team with an on-demand view of historical and incoming near-real-time data. The C3 AI team also integrated external data sources like Quandl and Demandbase to improve forecast accuracy with additional forecast signals.

C3 AI and the customer acted as a joint team to configure machine learning pipelines for C3 AI Demand Planning to build and train models using the most granular data. This data science approach enabled demand forecasts at all levels of granularity.

The team applied sparse data management techniques to address forecasting for new products, SKUs with limited data, and volatile demand. The team conducted time-series segmentation and feature-segment relationship mapping using additional data sources that C3 AI ingested to identify the right features that can generate more accurate forecasts.

After implementing the forecast models, the joint team configured a multi-screen user interface for model explainability. Demand planners can now explore model predictions and historical errors at any level of granularity and can aggregate and disaggregate data as needed to audit the predictions. Demand planners can also review individual forecast subjects and understand the main drivers of the AI forecasts. These intuitive AI evidence packages increased user trust and adoption.

About the Company

- $30 billion annual revenue in 2022

- 50,000+ employees globally

- 650+ product lines

Project Objectives

- Unify data from six internal and external sources (e.g., historical orders, product metadata, CRM).

- Develop and deploy high-accuracy, scalable AI models to forecast demand for SKUs at any level of granularity and for SKUs with limited data and/or volatile demand.

- Configure a workflow-enabled application to improve planner efficiency with exception management and AI explainability.

Project Highlights

- Integrated over 20 million rows of data spanning over three years. The data came from across six internal data sources (e.g., sales orders, CRM) and external data into the C3 AI Supply Chain Digital Twin.

- Reduced WAPE by 70 – 100% compared to previous ML models and consensus forecasting.

- Generated a 7% inventory reduction opportunity and $300 million company-wide cost savings due to more accurate demand forecasting.

- The configured workflow-enabled user interface provides model performance transparency and enables effective collaboration between data scientists and demand planners.

- AI evidence package explains AI forecast drivers.

Results

Solution Architecture

Benefits

- Reduced forecast errors (WAPE) by up to 100% over the baseline for all SKUs, leading to $300M savings potential at scale.

- Enabled accurate forecasting for products with limited historical data and/or volatile demand.

- Empowered demand planners to understand AI-generated forecasts with explainability.

- Provided a data foundation that enables rapid design, development, and deployment of a suite of C3 AI Supply Chain applications (e.g., Inventory Optimization, Production Schedule Optimization) to optimize customer’s supply chains further.