- AI Software

- C3 AI Applications

- C3 AI Applications Overview

- C3 AI Anti-Money Laundering

- C3 AI Cash Management

- C3 AI Contested Logistics

- C3 AI CRM

- C3 AI Decision Advantage

- C3 AI Demand Forecasting

- C3 AI Energy Management

- C3 AI ESG

- C3 AI Health

- C3 AI Intelligence Analysis

- C3 AI Inventory Optimization

- C3 AI Process Optimization

- C3 AI Production Schedule Optimization

- C3 AI Property Appraisal

- C3 AI Readiness

- C3 AI Reliability

- C3 AI Smart Lending

- C3 AI Sourcing Optimization

- C3 AI Supply Network Risk

- C3 AI Turnaround Optimization

- C3 Generative AI Constituent Services

- C3 Law Enforcement

- C3 Agentic AI Platform

- C3 Generative AI

- Get Started with a C3 AI Pilot

- Industries

- Customers

- Events

- Resources

- Generative AI for Business

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can the Generative AI Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- What Is Enterprise AI?

- Machine Learning

- Introduction

- What is Machine Learning?

- Tuning a Machine Learning Model

- Evaluating Model Performance

- Runtimes and Compute Requirements

- Selecting the Right AI/ML Problems

- Best Practices in Prototyping

- Best Practices in Ongoing Operations

- Building a Strong Team

- About the Author

- References

- Download eBook

- All Resources

- Publications

- Customer Viewpoints

- Blog

- Glossary

- Developer Portal

- Generative AI for Business

- News

- Company

- Contact Us

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can the Generative AI Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- C3 Generative AI: Getting the Most Out of Enterprise Data

- The Key to Generative AI Adoption: ‘Trusted, Reliable, Safe Answers’

- Generative AI in Healthcare: The Opportunity for Medical Device Manufacturers

- Generative AI in Healthcare: The End of Administrative Burdens for Workers

- Generative AI for the Department of Defense: The Power of Instant Insights

Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

By Venkat Raman, Senior Director, AI Solutions

September 27, 2023

The evolution of supply chains in the past couple of decades is a story of technological advances: logistics software that tracks items in near-real-real time; sensors everywhere, via the internet of things (IoT), that make that tracking possible, feeding data into supply chain management systems; the rise of cloud and edge computing; ever-improving connectivity (think 5G) to link it all; and enterprise AI applications to optimize scheduling, predict risks, and forecast demand.

We’re now in the early days of a major technological leap — generative AI — that’s poised to transform global supply chains in seemingly subtle yet powerful ways. With generative AI built for the enterprise, ensuring accuracy, security, and traceability, businesses can put all their supply chain technology to far better use, generating insights from vast amounts of data in minutes or hours versus weeks and months. Read that again: minutes and hours versus weeks and months. Generative AI is an advancement that supply chain managers will look back on and wonder how they managed without.

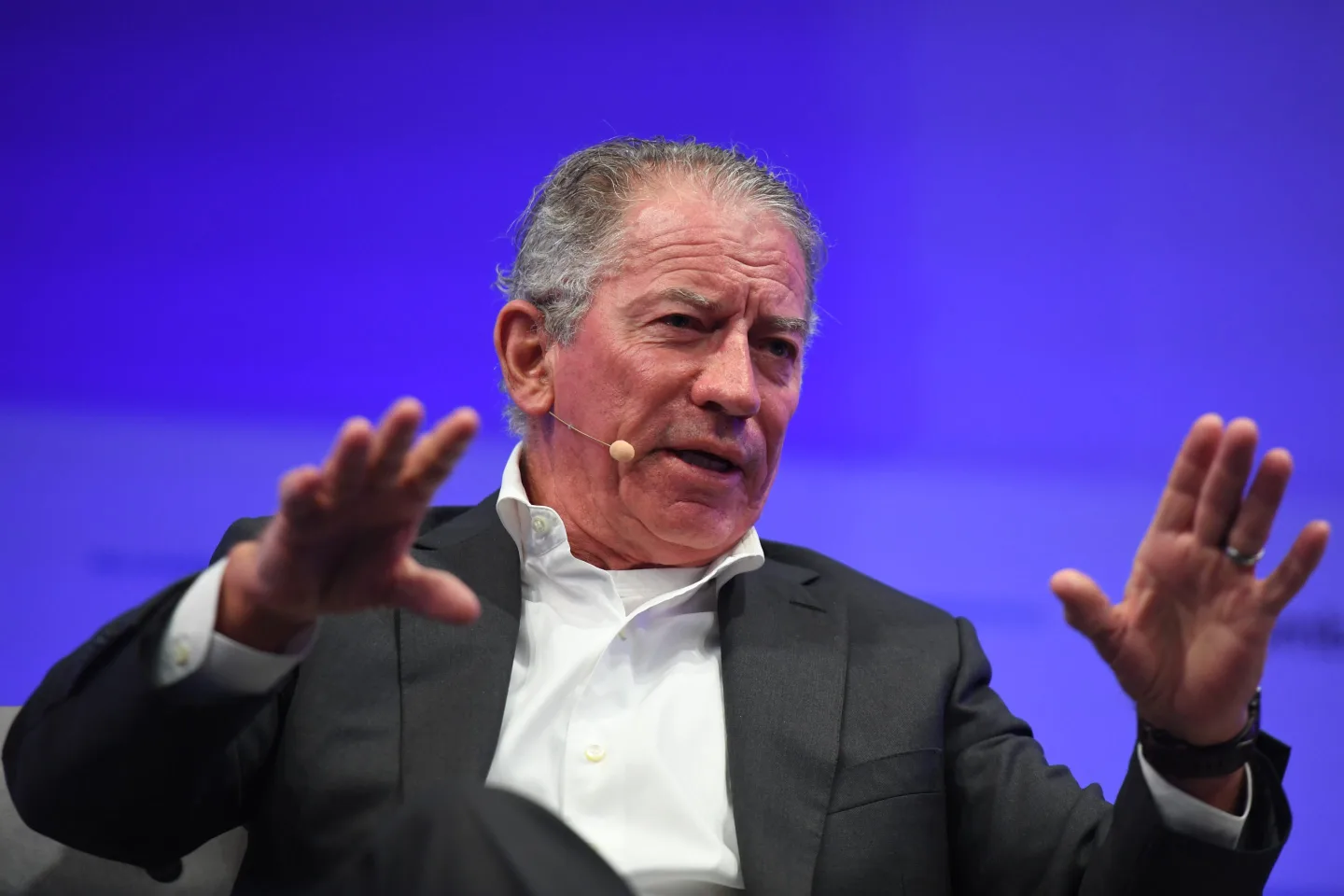

“Supply chains are becoming increasingly strategic for any global business,” said Jim Snabe, the former chairman of logistics-company Maersk, and current chairman of Siemens and C3 AI board member. “At the same time, they’re becoming more complex, and you deal with complexity with AI and generative AI. Only the companies that have an AI platform and generative capabilities will be able to thrive, because the new supply chain must be dynamic, and that requires supply chains to be predictive.”

Today, a single company can manage multiple tiers of suppliers spread across the world, manufacturing diverse products amid a complex web of facilities. Take, as an example, a global apparel manufacturer. Such a company’s supply chain requires a sophisticated infrastructure of warehouses, strategically positioned to house raw materials and finished goods for in-store and online fulfillment, including last-mile delivery across distant parts of the globe. Speed and reliability are critical. Every point in the process presents the possibility of delays or miscalculations, that could throw off forecasting plans and lead to excessive supply or product shortages.

The growing complexity of supply chains leads to an ever-swelling deluge of data. Research firm IDC found that data generated from industrial operations alone triples every five years. Such data is structured and unstructured, dispersed across different databases and systems. Adding to the challenge of the proliferation of data, tools, and systems, is that workers tend to operate in siloed environments, so turning all the data into useful information can become an arduous task.

Generative AI in Supply Chains: A New Opportunity

At this point, we’re all familiar with the ease and power of the consumer large language models (LLMs) that underlie generative AI tools such as ChatGPT and Google Bard. Type a question and, in a flash, you get an answer — a well-synthesized summary, or, depending on the tool, an AI-generated graphic or illustration. The capabilities are evolving at a rapid clip.

We’re also familiar with the flaws — the tendency of consumer LLMs to return incorrect answers, known as hallucinations, and inconsistent answers, all without any indication of where the LLM is getting the information from (known as traceability). Further, researchers have found that public LLMs also pose growing security threats. Yet a system that’s accurate and trustworthy enough for a business or government agency — C3 Generative AI is designed with such concerns in mind — can quickly improve how people work, what they can accomplish, and the speed at which it all happens.

The benefits are significant. With generative AI for the enterprise, supply chain professionals can swiftly get to the root causes of an issue instead of addressing the symptoms. Moreover, many people within an enterprise can help solve problems because generative AI is easy to use, akin to having a conversation. Ask questions. Get answers. All from your enterprise’s data, plus any external data an enterprise deems important for keeping its entire supply chain network operating smoothly — weather feeds, perhaps, or commodity prices.

As it now stands, many large manufacturers and retailers struggle with issues of all types that frequently emerge across their supply chain networks. It takes a lot less than a global pandemic or war to create supply chain problems.

The Complexity Challenge: Hunting for the Problem

Consider the situation a prominent athletic footwear company found itself in not long ago. The company procures its merchandise through a complex network of manufacturers scattered across the globe. Products for the North American market are stored in five geographically dispersed warehouses before being delivered to retail stores or directly to consumers who purchased online from the manufacturer.

Peak season was approaching when a warehouse manager discovered a concerning trend — capacity at a few of the company’s warehouses was shrinking fast, threatening to leave the company with nowhere to store products.

The company quickly assembled a roughly 30-person team — experts from warehouse operations, inventory management, material planning, procurement, and outside consultants —to figure out what was going on. According to a consultant involved with the project, the team came up with three interim solutions that the company implemented: It introduced additional pallet storage, converted office spaces at the warehouses into storage areas, and it used trailers in parking lots as makeshift storage units. (The company also launched a long-term plan to build additional large warehouses.)

Such short-term solutions, common when companies get in a bind, tend to neglect the underlying issue or issues, which remain hidden beneath layers of intricate data. Company executives, and the team assembled to hunt for the cause of the problem, were perplexed and frustrated, especially given the rigorous planning that goes into warehouse space requirements to prepare for the peak sales season.

The team dug in, asking logical questions: Were products not selling? If so, which ones? If so, why not? Further, why aren’t our systems (and people) aware of the falloff in demand? Did we do a bad job forecasting demand and simply buy too much? Or is the problem technical, where the information transmitted about capacity or order churn is incorrect? If so, why? And on and on.

Warehouse analysts looked at data trends on warehouse management systems (WMS), searching for clues across inventory levels. Eventually, the inventory managers on the team discovered unusual patterns that revealed a sluggish turnover of tennis shoes. Demand for tennis shoes was stable, however, so the excess inventory wasn’t caused by a slowdown in sales.

The team kept probing. Through work with the demand planners, the group discovered considerable fluctuation in lead times by a key supplier of tennis shoes. Deeper analysis showed that this supplier had recently relocated its manufacturing operations from Mexico to East Asia, resulting in erratic lead times as the supplier adapted to the new geography and was ramping its logistics and manufacturing capabilities.

At last, puzzle solved. The variability in lead times triggered what’s known as the bullwhip effect, a phenomenon that describes increasingly large swings in inventory levels triggered by small changes in demand or orders from suppliers. This led inventory managers to stockpile inventory as a buffer against fluctuating lead times and supply variabilities. That, in turn, only made the inventory problem worse.

As a solution, the company immediately began looking for alternative sources for tennis shoes while the primary supplier stabilized its operations.

This all took many long days of analysis and data hunting. Along the way, experts from elsewhere in the company were pulled in as needed, including category planners, and forecasting specialists. Data extraction from various systems — including WMS, order management, inventory management, supplier contracts, procurement, and transportation — posed a considerable challenge since these systems used different software platforms, such as SAP, Oracle, and specialized software for specific functions. The complexity made data retrieval a daunting task; moreover, critical information was buried within unstructured data sources such as PDF documents and HTML pages.

Ultimately, getting to the root cause of the issue took a very busy three months, with help from people far beyond the core team of 30 or so assembled to attack the problem.

Putting Generative AI to Work in Supply Chains

With C3 Generative AI for Supply Chains, companies can rapidly find and fix problems. C3 Generative AI offers a natural language interface prompt, and the ability to query structured and unstructured data within an enterprise, all with important safeguards that would make it easy to address the tennis shoe overflow problem.

How to begin? As always, with the data.

As part of any generative AI integration, C3 AI maps all the data coming from all enterprise systems, such as ERP, CRM, SCADA, sensors, HTML, PDFs, WMS, and so on. If it’s part of—or important to—running your supply chain, we ingest that data and put it to work for you. All this data gets mapped to a supply chain digital twin, creating an exact replica of the end-to-end view of your supply chain at a granular level. This system tracks every order, at every step, in real time. A number of other safeguards are in place so that the LLMs are suitable for the enterprise — secure and accurate.

C3 Generative AI for Supply Chain

Then, we add the C3 Generative AI solution for supply chains. Instead of assembling a supply chain swat team to figure out why warehouse capacity is shrinking, a couple of key people — a supply chain specialist, for instance, working with the warehouse operations manager who first noticed the problem — could figure out the problem and a recommended solution.

Immediately after discovering a problem, the supply chain specialist could open up the generative AI tool, and begin to probe via a series of prompts, with each answer getting closer to the root cause. When appropriate, the system provides charts and graphics; it also provides links to the source material, so the user knows exactly where the answers are coming from — an important distinction from other generative AI tools.

The conversation would go like this:

Next, the supply chain specialist would ask if the slowdown in inventory turn — 3.5 in September 2023 shows growing backlog at the warehouses — is due to a problem with the forecast, or an unexpected drop in demand, or over ordering. To which the generative AI tool, retrieving information from the forecasting and demand planning systems, answers that no unexpected drop in demand has occurred, and that the forecast accuracy for tennis shoe demand has been over 95%.

As you can see, generative AI lets the person querying the tool – conversing with all the data – continue to probe without the laborious work required without generative AI.

The conversation goes on, with the system explaining that a specific tennis shoe supplier has performed poorly in the last two quarters, failing to consistently meet service level agreements, among other issues. In short, the generative AI tool provides precise answers to problems that took the 30-person team months to uncover.

Further, the generative AI tool can suggest solutions. In this case, it recommends a supplier — call it Supplier Y — that the company has ordered from before, has a solid track record, and has the capacity to boost supply. All this information comes from the company’s quarterly business review (QBR) reports and supplier risk assessment reports.

This process alone – finding and evaluating the best back-up supplier—could take days, if not weeks, without generative AI. Instead, generative AI cranks out answers in a matter of a few minutes.

Yes, minutes.

Even so, a major company shouldn’t make critical supply chain decisions based on an answer produced in a few minutes from generative AI. A team will still want to evaluate the findings. Yet the opportunity for efficiency and flexibility is enormous. The way that generative AI can help isolate a problem, and recommend fixes, is the beginning of a new era for major businesses and governments the world over, all of which are rethinking how their supply chain networks are put together and how to best withstand constant hiccups as well as the next pandemic-like Black Swan event.