- AI Software

- C3 AI Applications

- C3 AI Applications Overview

- C3 AI Anti-Money Laundering

- C3 AI Cash Management

- C3 AI Contested Logistics

- C3 AI CRM

- C3 AI Decision Advantage

- C3 AI Demand Forecasting

- C3 AI Energy Management

- C3 AI ESG

- C3 AI Health

- C3 AI Intelligence Analysis

- C3 AI Inventory Optimization

- C3 AI Process Optimization

- C3 AI Production Schedule Optimization

- C3 AI Property Appraisal

- C3 AI Readiness

- C3 AI Reliability

- C3 AI Smart Lending

- C3 AI Sourcing Optimization

- C3 AI Supply Network Risk

- C3 AI Turnaround Optimization

- C3 Generative AI Constituent Services

- C3 Law Enforcement

- C3 Agentic AI Platform

- C3 Generative AI

- Get Started with a C3 AI Pilot

- Industries

- Customers

- Events

- Resources

- Generative AI for Business

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can the Generative AI Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- What Is Enterprise AI?

- Machine Learning

- Introduction

- What is Machine Learning?

- Tuning a Machine Learning Model

- Evaluating Model Performance

- Runtimes and Compute Requirements

- Selecting the Right AI/ML Problems

- Best Practices in Prototyping

- Best Practices in Ongoing Operations

- Building a Strong Team

- About the Author

- References

- Download eBook

- All Resources

- Publications

- Customer Viewpoints

- Blog

- Glossary

- Developer Portal

- Generative AI for Business

- News

- Company

- Contact Us

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can the Generative AI Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- C3 Generative AI: Getting the Most Out of Enterprise Data

- The Key to Generative AI Adoption: ‘Trusted, Reliable, Safe Answers’

- Generative AI in Healthcare: The Opportunity for Medical Device Manufacturers

- Generative AI in Healthcare: The End of Administrative Burdens for Workers

- Generative AI for the Department of Defense: The Power of Instant Insights

Generative AI in Healthcare: The Opportunity for Medical Device Manufacturers

By Nicholas Siebenlist, Solution Director, Healthcare, C3 AI

December 4, 2023

Medical device manufacturers that make rehabilitation and lifesaving products like orthopedic joint replacements and cardiac monitors are under growing pressure to enhance operational resilience and develop products that give patients the highest quality of life. Companies have seen revenue growth slow substantially, increasing only 3.5% in 2022 compared to 16% in 2021 — due partly to limited innovation. To address this, device manufacturers are seeking novel ways to reduce costs and increase revenue.

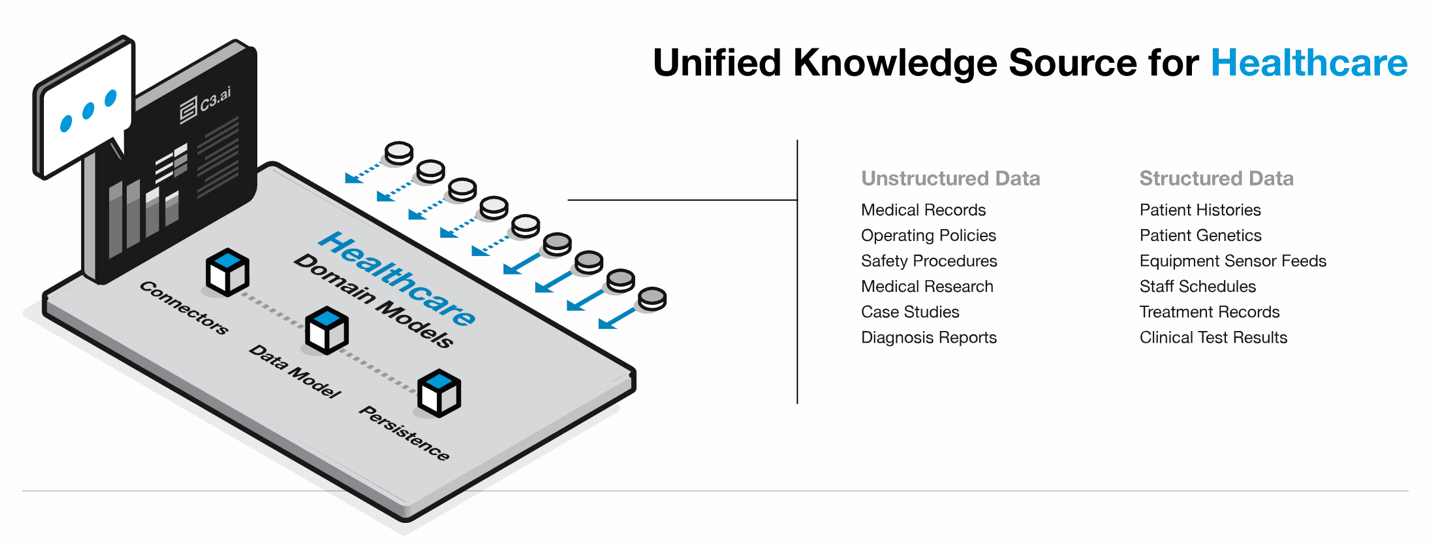

Healthcare Generative AI offers both immediate solutions and immense future potential. It provides a new, powerful opportunity for medical device manufacturers to get more out of one of their most valuable assets — their data — to drive innovation and address the growing costs associated with supply chains and product quality.

During product development and delivery, medical device manufacturers produce and collect vast amounts of structured and unstructured data, including customer feedback, research and development practices, product manufacturing, and information from clinical trials. This data, and external data such as peer reviewed literature, are essential to optimizing product development. Put simply, data fuels innovation, making generative AI an invaluable technology for device makers, all of whom are competing in a landscape where healthcare demands are increasing across the board.

Using C3 Generative AI for Healthcare, medical device manufacturers can:

- Increase innovation

- Increase product quality

- Avoid recalls

- Forecast product demand

- Optimize inventory levels

Generative AI in Healthcare: Helping R&D Engineers Innovate Faster and Prevent Failures

Clinical standards and patient expectations for high-quality devices, such as demand for remote patient monitoring devices, drive medical device manufacturers to innovate while maintaining safety and regulatory standards.

To innovate effectively, research and development engineers rely on an endless trove of documents: published scientific literature, internal standard operating procedure (SOP) documents, details of past experiments, and product feedback. These are used to model, design, document, and publish product development research. A cardiac device R&D engineer, for example, must search across multiple disparate sources including PubMed, internal CAD designs, sister product failure reports, and material property databases. With C3 Generative AI, a cardiac device R&D engineer can search and interact with internal and external data directly to rapidly get accurate answers to such questions as:

- What are the failure modes for heart valve devices?

- What are the latest meta studies on left ventricular assist devices (LVAD)?

- What are the existing CAD designs for a thoracic aortic graft?

McKinsey estimates that generative AI can increase worker productivity up to 60%. Further, being able to derive quick, dependable insights from all your data can improve design effectiveness. The benefits of applying C3 Generative AI are reducing R&D costs and reducing failure events, preventing product recalls.

Generative AI in Healthcare: Supply Chain Managers Plan for Demand and Optimize Inventory Levels

Medical device makers are adjusting to post-pandemic healthcare operations. Specialized medical device need has grown, while elective procedures have been postponed or cancelled, creating significant fluctuations in product demand with a growing patient backlog.

For example, demand for interbody fusion devices used in back surgery can decrease when inpatient bed availability decreases because such procedures can require overnight stays. Forecasting and stocking are further complicated by factors such as long lead times and competition.

Using internal data such as sales orders and customer information, as well as external data such as epidemiology studies and hospital reports, are essential to solving this challenge. Accurate forecasts and stock levels ensure product availability so patient needs are met, without overstocking product and incurring unnecessary costs.

With C3 Generative AI for Supply Chain, supply chain managers can search and interact with internal and external data directly to ask questions such as:

- What are my inventory levels for all orthopedic knee joint products?

- How is demand for permanently implanted cardiac devices changing in the mid-Atlantic?

- How many temporary implanted devices have had stock outs in the past three months?

Generative AI can enable supply chain managers and others to efficiently search, source, and understand key processes and changing business operations in their supply chain. The outcome is a streamlined supply chain with fewer stock outs, higher service levels, reduced inventory costs, and more accurate demand forecasts.

C3 Generative AI for Supply Chain

Generative AI in Healthcare: Reliability Engineers Access Knowledge from Across the Workforce

Medical device manufacturers face significant financial and reputational costs when low quality products don’t function as they should, representing losses of 3.8% of total sales and risking patient safety. Low quality products can be due to sub-standard materials, machinery errors, software malfunction, and improper device design. In significant cases, product recalls due to unforeseen failure modes can be devastating when not detected during quality assessments.

Reliability and quality engineers are responsible for ensuring medical devices are designed to specification, meet quality standards, and are safe for patients. This process requires significant testing and documentation to ensure regulatory standards and best practices are met. To effectively document quality testing and resolve product manufacturing issues, engineers must consult disparate data sources including product manuals, error guides, historical resolution documentation, and machine sensor data.

With C3 Generative AI, engineers can search and interact with internal and external data directly to ask questions such as:

- Has this particular failure mode occurred before and how was it resolved?

- What were the sensor values leading up to low quality product creation?

- How does the product guide recommend testing possible failure causes?

Generative AI is transforming healthcare operations, including manufacturing reliability engineering. By using C3 Generative AI, healthcare manufacturers can increase engineer productivity and accelerate onboarding by unlocking reliability engineering knowledge hidden within siloed databases. Furthermore, C3 Generative AI can accelerate reliability engineering resolution and improve product quality measures, directly improving revenue.

Generative AI in Healthcare: Risks and Concerns

Integrating new technology, such as generative AI, in healthcare manufacturing carries risks to data and privacy. Utilizing patient data, documenting medical decision making, and accessing sensitive company data require any generative AI solution to have the appropriate access controls and have the ability to apply anonymization or deidentification where appropriate.

Critical processes and decisions in healthcare manufacturing can’t be made with a generative output that lacks transparency — all roles require traceability of source material when searching across disparate data systems — so generative AI outputs must give users the option to view the data behind an output, in context, to make an informed and documented decision.

Hallucination is an unacceptable output that could have consequences to the business, and ultimately, patients. Research and development, demand forecasting on price, and proprietary products in clinical trials all require sensitive data, and the use of large language models (LLMs) in generative AI products brings a risk of data leakage.

C3 Generative AI addresses all these risks and concerns with a product that provides full traceability for all results without hallucination, protects patient data with HIPAA and GDPR certifications, including robust business-wide access controls, and prevents leakage of proprietary information with a walled garden product deployment, so no company data leaves your network.

Generative AI in Healthcare: The Opportunity

Medical device manufacturers have an opportunity to implement generative AI now to solve core business challenges in a post-pandemic marketplace. A technology solution that protects patients and data is key to successful implementations that serve as the foundation for enterprise transformation. Device manufacturers that embrace generative AI will have a strategic advantage over competitors with higher product quality, a more resilient supply chain, and increased innovation.