Chemical Manufacturer Improves Critical Asset Availability with Enterprise AI

Download the PDF to read the full story - Download

Challenges

A global chemical company had a strategic priority to improve utilization of its production lines and process units, focusing first on its fleet of steam cracking furnaces. Steam cracking furnaces are critical in the process of converting lower-value petrochemical feedstocks into high-value olefins, as unplanned downtime of furnaces translates directly to lost production.

Prior to engaging with C3 AI, the company relied on standard monitoring tools to manage the health of furnaces. The existing solutions provided univariate, threshold-based alarms, and limited visibility or early warning of critical reliability issues to operators. As a result, they faced high variability in maintenance needs and sub-optimal decoking schedules for furnaces.

The company decided to partner with C3 AI to deploy an application on Microsoft Azure that can:

- Predict furnace failures in 5 days in advance to reduce unplanned events

- Predict and forecast furnace coil coking rates and critical limits to extend run lengths from 40 to 50 days

- Scale across a global fleet of steam cracking furnaces to improve global operations

Approach

In a 12-week initial production deployment, C3 AI partnered with the chemicals company to configure C3 AI Reliability to predict failures and to forecast coking progression for two steam cracking furnaces.

The team configured the application by first ingesting, cleansing, and unifying two years of historical data from 7 systems, including sensor data, maintenance data, asset hierarchy, asset utilization, engineering drawings, condition-based monitoring, and quality data. Using the unified data image, the C3 AI team developed and tested over 20 machine learning (ML) models to predict furnace failures using advanced anomaly detection. The team also developed 4 models to forecast coking progressions.

C3 AI trained over 20 reliability engineers and operators to use the application, investigate AI evidence packages, and take corrective action. The team also trained 4 customer data scientists and data engineers to use the C3 AI Platform to configure, train, validate, and deploy ML models to scale predictive maintenance across their organization.

Finally, the team configured a workflow-enabled C3 AI Reliability 10-page user interface to visualize AI-based furnace health and coking forecasts. The application provides a complete workflow for an asset engineer to review and investigate AI-based alerts, create cases to document investigation, and submit work orders for maintenance needs.

About the Company

- Operates in 150+ countries

- $50+ billion annual revenue in 2023

- 30,000+ employees

Project Objectives

- Enable predictive monitoring capabilities for critical equipment in olefin manufacturing, starting with steam cracking furnaces

- Increase asset utilization for steam cracking furnaces through improved furnace reliability

- Increase production by extending furnace run lengths with improved visibility into furnace coking rates

- Expose AI insights and unified analytics to end users through an intuitive user experience

Project Highlights

- 2+ years of data from 7 enterprise systems unified, including 750 sensors and 180 million rows of timeseries data

- 24 ML models trained and tested to predict steam cracking furnace failure

- 10 C3 AI Reliability application user interface screens configured

- 4 customer data scientists onboarded and trained to deploy models to scale C3 AI Reliability to additional furnaces and new assets

- 20+ end user engineers and operators onboarded through live and online training workshops

Results

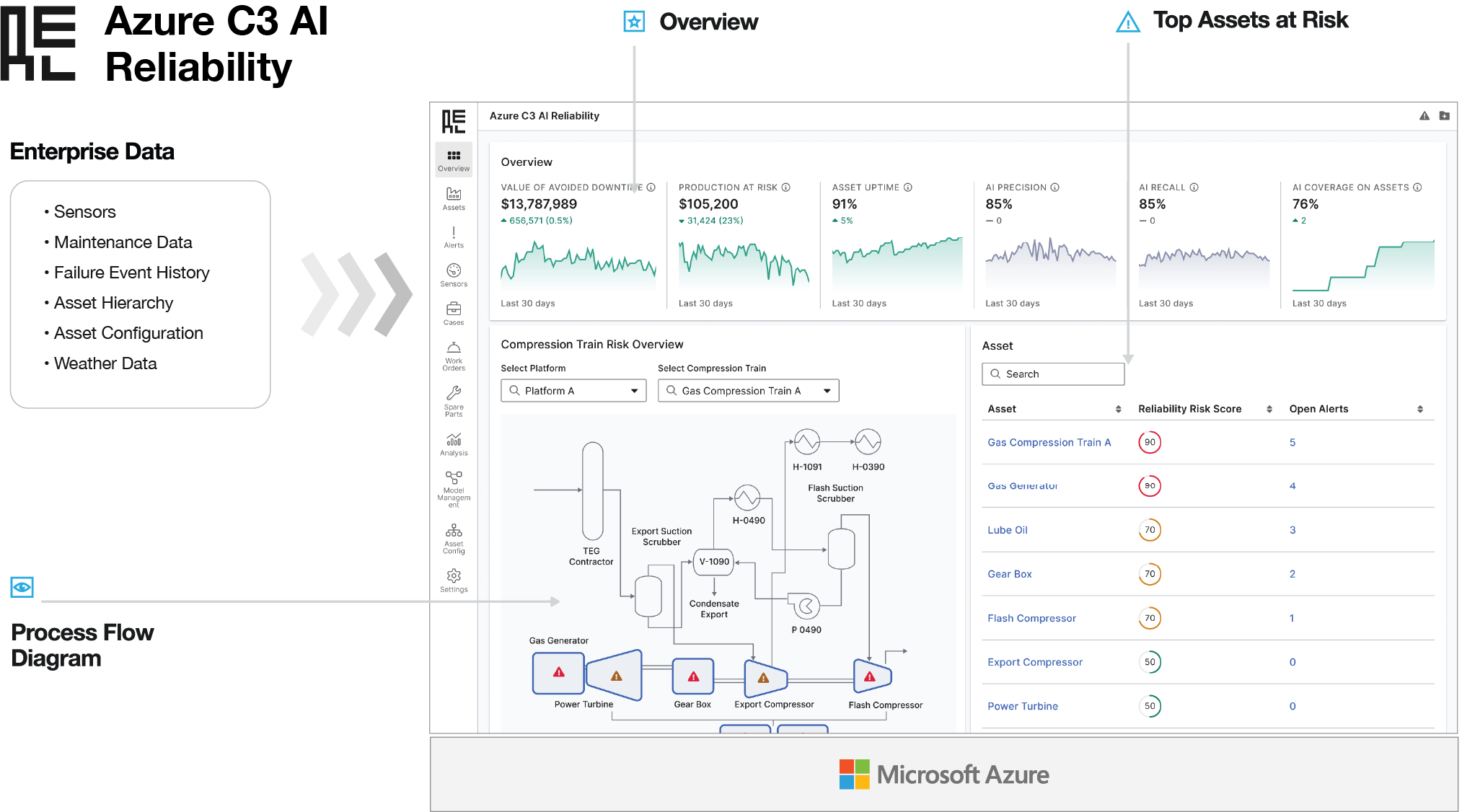

Solution Architecture

Benefits

With C3 AI and the C3 AI Reliability application, the chemicals company is now able to:

Generate

$45+ million in economic benefit at scale-out to global fleet of 200 steam cracking furnaces

Improve

utilization of steam cracking furnaces by 1.5%

Forecast

coking rate with 5-day look-ahead to efficiently plan maintenance activities

Extend

average furnace runs by 10+ days, from 40 to 50+ days

Monitor

asset health and coking progressions for steam cracking furnaces in near real-time with advanced machine learning

Scale

predictive maintenance across global operations with a flexible, fast-to-deploy AI application

Expand

AI use cases to new business challenges with a flexible, scalable AI platform, such as improving supply chain visibility