Contract Manufacturer Achieves 2.8% Revenue Uplift with AI Scheduling

Value-Driven Benefits

Download the PDF to read the full story — Download

Introduction

A global leader in contract manufacturing and supply chain solutions operates in over 30 countries and across complex sectors such as electronics manufacturing. With a dynamic supply chain and demand volatility, the company faced increasing challenges in meeting customer demand, optimizing production, and controlling inventory costs.

Challenges

However, the company relied on conventional planning methods, such as first-in-first-out (FIFO) or manual adjustments to manage production. While adequate for basic scheduling, these systems couldn’t adapt to real-time disruptions such as material shortages or shifting capacity. Due to the inability to shift its production flexibly, the company missed high-value opportunities, accumulated excess and obsolete (E&O) inventory, and depended on costly off-schedule work orders to meet customer orders.

Solution

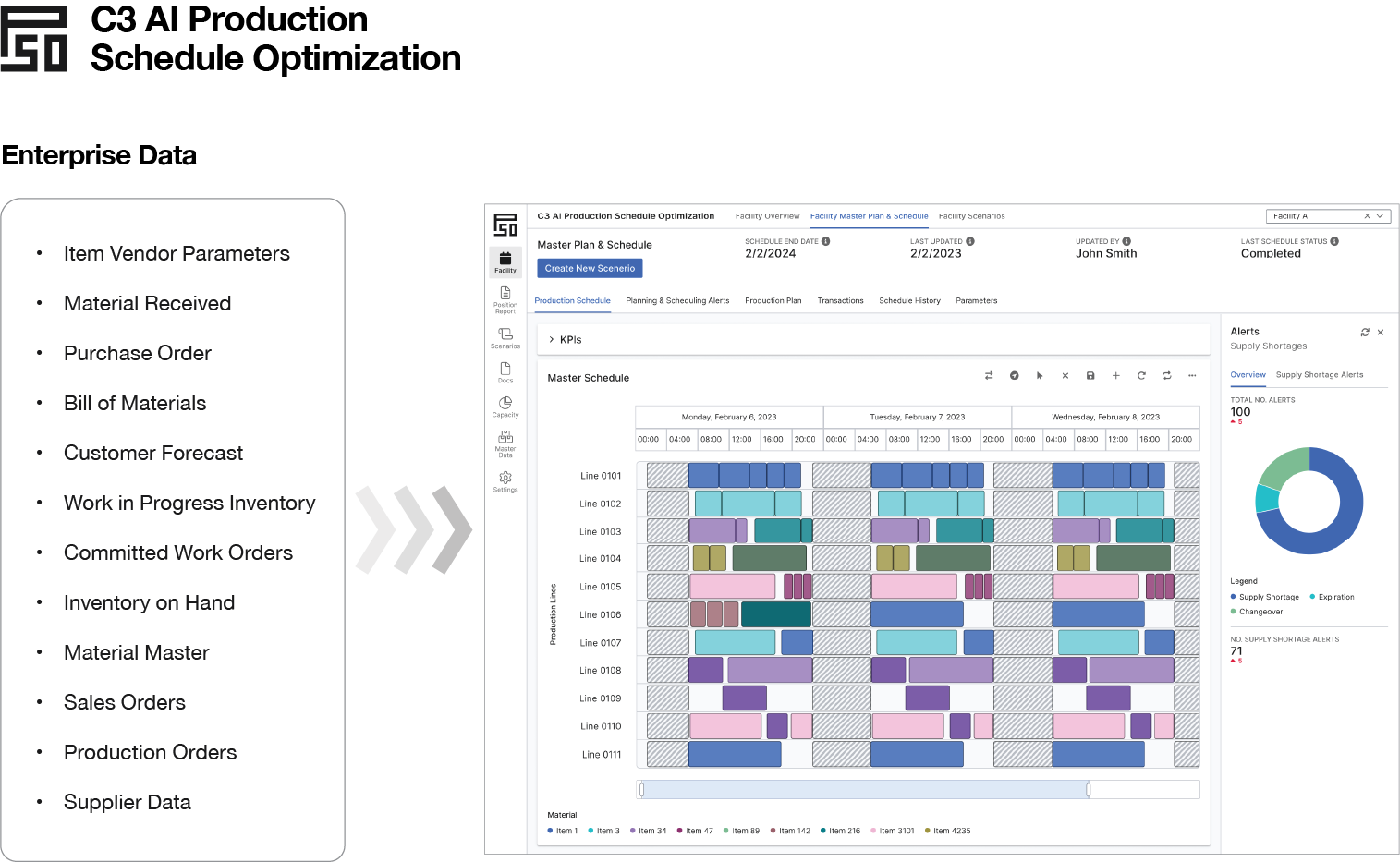

To address these challenges, the company partnered with C3 AI to implement an AI-driven solution for complex production scheduling, the C3 AI Production Schedule Optimization (PSO) application. Within 12 weeks, the team deployed C3 AI PSO to 6 production lines, unified data from 10 disparate sources, and configured a powerful optimization engine that evaluates up to 130,000 potential sequences per manufacturing run. With C3 AI PSO, planners can review optimization recommendations tied to business KPIs and flexibly update production schedules to drive better business performance.

Results

With the initial deployment of C3 AI PSO, the company anticipates an estimated annual revenue lift of 2.8% across 6 production lines and over $37 million of economic value when scaled across its facilities. Building on this success, the company is expanding its partnership with C3 AI to 5 additional AI use cases across its supply chain, including inventory and sourcing optimization.

About the Company

- $36+ billion in annual revenue

- 30+ countries of operation

- 800+ program facilities worldwide

- 150,000+ employees

Project Highlights

- 12-week initial production deployment

across six diverse production lines - 300,000+ records from 10 enterprise data

sources integrated - 130,000 production sequences evaluated

per run by AI-powered optimization engine - C3 AI Production Schedule Optimization

application user interface configured

Solution Architecture

Proven results in weeks, not years

Take the Next Steps

Learn how our industry-leading Enterprise AI software products can help your organization.

Contact us at IR@C3.ai to learn more about investing at C3 AI.

For all other questions, please contact us here.