Improve Uptime and Asset Reliability

Download the PDF to read the full story - Download

Challenges

Centrifuges are critical assets in the upstream stage of the biomanufacturing process. As centrifuges harvest the proteins necessary for downstream purification, unplanned centrifuge failures can halt operations and cause plants to miss a production slot entirely, reducing run rates and the number of batches produced. Unanticipated failures can also result in product being discarded from centrifuges, resulting in millions in lost revenue.

In addition to not being able to predict centrifuge failures, site operators at the biotechnology company were inundated with false and inadequate alerts. The existing rules-based monitoring systems produced upward of 60 alerts a month. However, the alerts achieved only recall of 13% and precision of 29%, meaning that 87% of actual failures were not captured and that 71% of alerts were false alarms. Moreover, the current system provided an average of only 45 minutes of lead time before a shutdown, leaving operators with a narrow window for preventative actions.

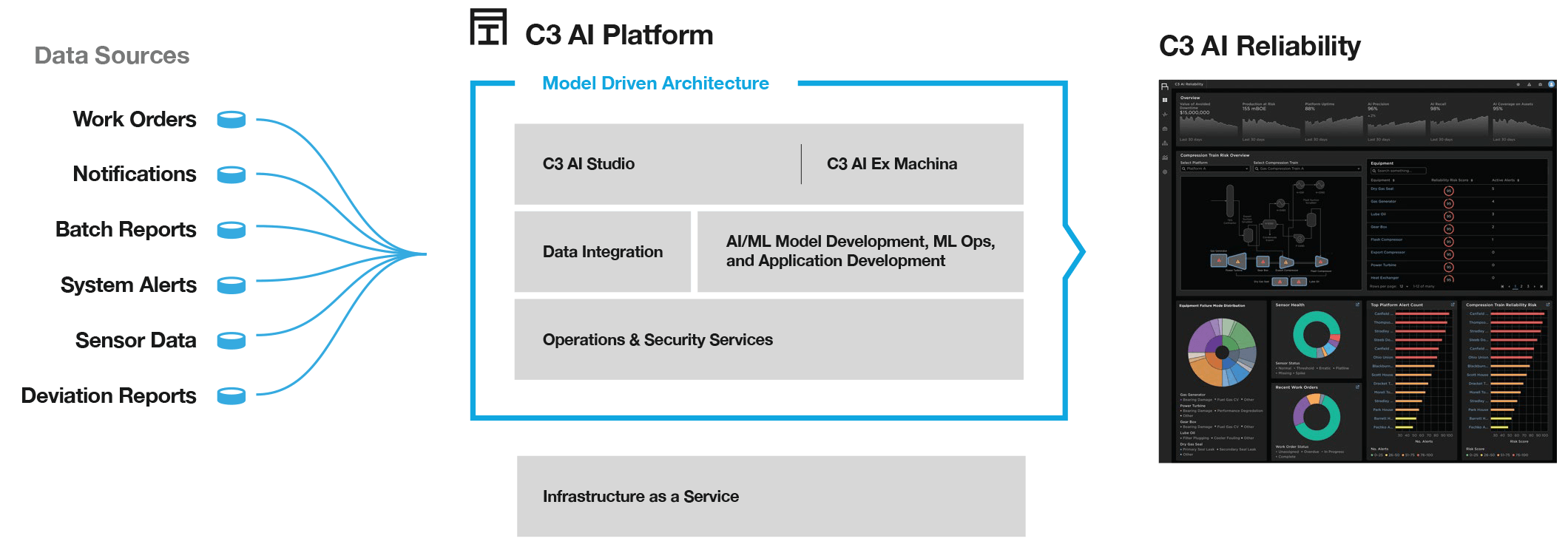

The existing rules-based system cannot flexibly incorporate new data sources or adjust preset sensor thresholds to improve the accuracy or comprehensiveness of alerts. An AI-led approach would be able to integrate all relevant data sources and apply advanced ML techniques on top of unified data to improve the recall and precision of failure predictions.

To address these challenges and implement an AI-driven approach to centrifuge monitoring, the biotechnology company chose C3 AI Reliability.

Approach

Over 12 weeks, the C3 AI team worked with subject matter experts at the biotechnology company to configure the C3 AI Reliability application to surface predictive and prescriptive insights for 3 centrifuges.

The team began by ingesting and unifying over 6 years of historical data from 6 disparate systems, including batch reports, work orders, system alerts, sensor data, and deviation reports, to create a unified data model.

The team applied advanced machine learning techniques to the unified data model, experimenting with many proven and state-of-the-art ML approaches and testing over 500 ML model configurations to identify the optimal models for predicting centrifuge failures.

Finally, the C3 AI Reliability user interface was configured to surface AI-based alerts and prescriptive insights. User-friendly dashboards provide high-level site and asset KPIs, prioritized AI alerts, and details for risk investigation and mitigation.

C3 AI Reliability reduced the number of alarms generated by 80%, from 60 to 10 alerts per month; improved the number of impending failures predicted by 80%, from 13% to 93%; and increased lead time by 48x, from 45 minutes to more than 2 days.

About the Company

- $60B+ annual revenue

- 15M+ patients worldwide

- 10+ manufacturing sites

Project Objectives

- Integrate and unify over 6 years of historical data from 6 disparate data sources

- Apply machine learning to predict centrifuge failures in advance

- Configure C3 AI Reliability user interface to surface AI insights and unified analytics for end users

Project Highlights

- 12 weeks from kickoff to pre-production application

- Integrated over 6 years of historical data from 6 enterprise IT systems

- Developed over 300 reusable analytics

- Tested over 500 machine learning model permutations

- Configured C3 AI Reliability application user interface

Results

Solution Architecture