Leading Chemical Manufacturer Improves Energy Efficiency with AI

Challenges

A leading petrochemical company is a top producer of high-quality ethylene, polyethylene, and 1-hexene products. Sustainability is integrated into the company’s business strategy and the company invests significantly in developing and deploying technologies to improve end-to-end energy efficiency and reduce emissions across its operations.

In 2022, before partnering with C3 AI, the company established a sustainability program to increase its energy efficiency performance. A key pillar of the program was to establish energy and emissions baselines to ensure accurate reporting and identify opportunities for improvement. The team developed an effective methodology to quantify consumption and emissions, but the calculation process was manual and time consuming, limiting the team’s ability to provide real-time emissions visibility. Due to the manual calculation process, the team also lacked the necessary real-time, equipment-level energy consumption analytics to drive actionable improvements.

Approach

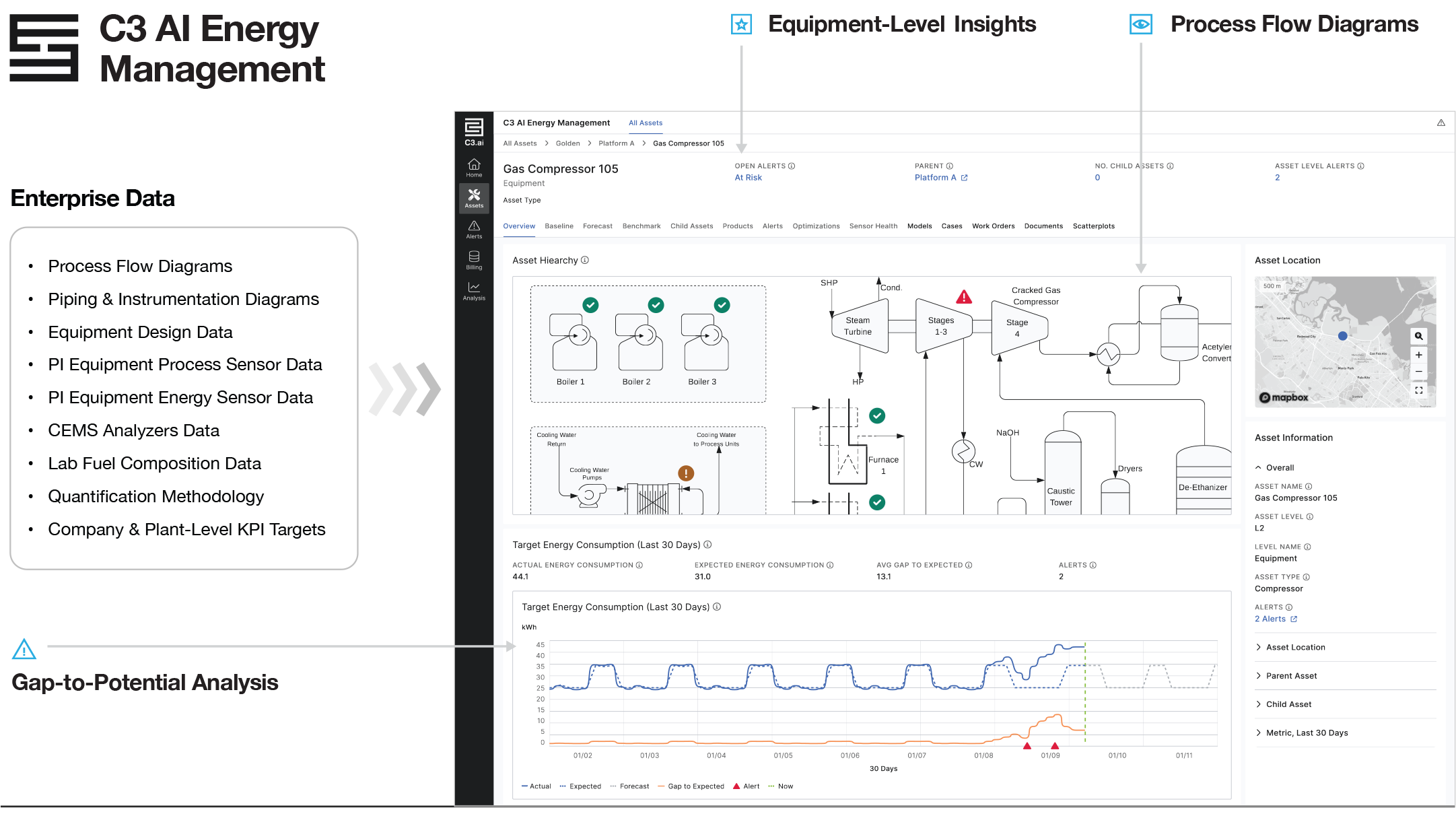

Over 7 months, C3 AI partnered with the company to configure and deploy C3 AI Energy Management to monitor 14 equipment units in an ethylene plant. The team started by ingesting over 5 years of process and operational data such as process flow diagrams, P&IDs, equipment design data, sensor data, and lab data to create a unified data image.

The team applied advanced analytics and ML models on top of the unified data image to enable near real-time gap-to-potential analysis and peer-to-peer benchmarking at the equipment and facility level. The application alerted users of anomalous energy and fuel consumption based on the difference between actual and AI-expected behavior. Sustainability managers can utilize the granular insights and prioritized alerts to identify and prioritize maintenance and capital cost initiatives to maximize energy cost savings and emissions.

To automate GHG emissions calculations, the C3 AI team used stoichiometric methodologies as well as the company’s quantification models and industry emissions factor libraries, to convert fuel and electricity consumption into GHG emissions with high accuracy. With automated emissions calculations, the company could eliminate the manual data gathering process, enable continuous emissions visibility, and streamline reporting.

About the Company

- State-owned petrochemical company

- 2 world-class ethylene plants

- 1.25 million metric tons of polyethylene production annually

- 1,200+ employees

Project Objectives

- Provide visibility into equipment-level energy and emissions efficiency

- Enable a single source of truth into overall sustainability performance of ethylene unit

- Leverage data-driven insights to meet sustainability objectives

- Configure the C3 AI Energy Management application to visualize and interact with ML insights in a user-friendly interface

Project Highlights

- 5 years of minute-level frequency data and 1B rows of timeseries data integrated

- 500+ equipment sensors across 14 equipment units and 5 equipment types included

- 16 machine learning models developed

- 200+ custom emissions metrics configured

- Configured the C3 AI Energy Management application user interface, including 2 new customer-specific screens

- Deployed on Microsoft Azure

Results

Solution Architecture