Protein Producer Saves 25% in Energy Costs with AI Process Optimization

Value-Driven Benefits

Download the PDF to read the full story — Download

Introduction

A leading, vertically integrated North American protein producer operates over 40 protein processing plants across the globe. However, the company lacked an effective method to track and manage its facilities’ energy usage and aimed to implement an AI-driven solution to reduce its global energy consumption and costs, starting with its most energy intensive systems — the ammonia refrigeration systems.

Challenges

Ammonia refrigeration systems and its compressors are essential for maintaining cold operating and storage temperatures but are one of the main drivers of energy consumption in protein processing. Due to stringent regulations and to avoid any risk of temperature increase, plants run compressors at full capacity even when ambient temperatures are low and invest in 100% backup compressor redundancy. However, poor load balancing of compressors led to higher energy consumption and increased maintenance cycles.

Moreover, the plants depended on OEM systems to monitor refrigeration health. However, these conventional systems were difficult to navigate and lacked the analytical tools to project and recommend optimal process parameters based on historical and real-time data. Consequently, engineers reacted in real-time to abrupt changes in ambient temperatures and resorted to costly short-term risk mitigation strategies.

Solution

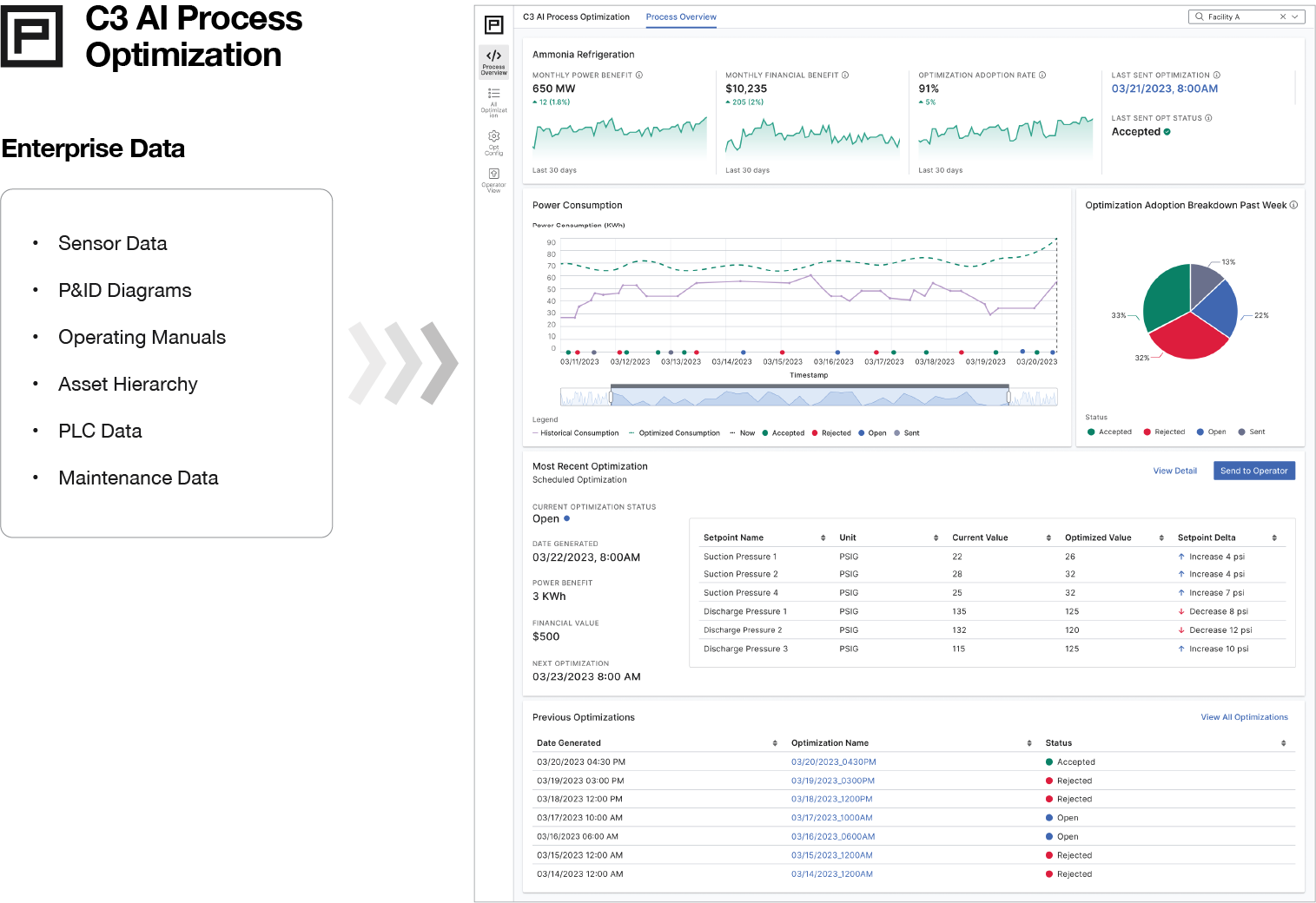

To address these challenges, the company partnered with C3 AI to implement C3 AI Process Optimization, an AI-enabled application to optimize its energy consumption. Within 24 weeks, the C3 AI and customer team configured and deployed C3 AI Process Optimization at one of its processing plants to recommend optimal process setpoints every four hours for the ammonia refrigeration system. With C3 AI Process Optimization, the operators gained a comprehensive view of all the decision variables and a new capability to predict maximum consumption load every four hours to optimize energy usage continuously.

Results

During the initial production deployment, C3 AI demonstrated that C3 AI Process Optimization can help the company save over 25% in energy costs for its ammonia refrigeration systems. When deployed across its operational footprint, the company anticipates C3 AI Process Optimization will help it achieve up to $9M in annual economic benefit from energy cost savings and improvements in operational efficiency.

About the Company

- 40+ protein production facilities

- 600 GWh in annual energy consumption for ammonia refrigeration systems

- 30,000+ employees

Project Highlights

- 24-week initial production deployment

- 200+ sensors and historical minute-level

data integrated from across the refrigeration

system - 15 ML models with 100+ underlying novel

features developed to track and simulate

the refrigeration system - C3 AI Process Optimization application user

interface configured - 24 users trained

Solution Architecture

Proven results in weeks, not years

Take the Next Steps

Learn how our industry-leading Enterprise AI software products can help your organization.

Contact us at IR@C3.ai to learn more about investing at C3 AI.

For all other questions, please contact us here.