Sugar Manufacturer Increases Yield with AI-Driven Setpoint Recommendations

Download the PDF to read the full story - Download

Challenges

One of the largest sugar manufacturers in Latin America produces over 1 million tons of sugar and byproducts each year and distributes its products in over 40 countries worldwide. The company’s top priority is to optimize yield across its harvesting and manufacturing process, allowing it to maximize sugar production and revenue.

Prior to engaging C3 AI, the manufacturer tried to increase yield with a traditional machine learning (ML) approach that identified process variables contributing most to sugar recovery. However, it struggled to unify sensor and lab measurement data recorded at different frequencies and had to rely on daily averages for process variables. This approach did not provide operators with timely insights to adjust setpoints and optimize yield.

Approach

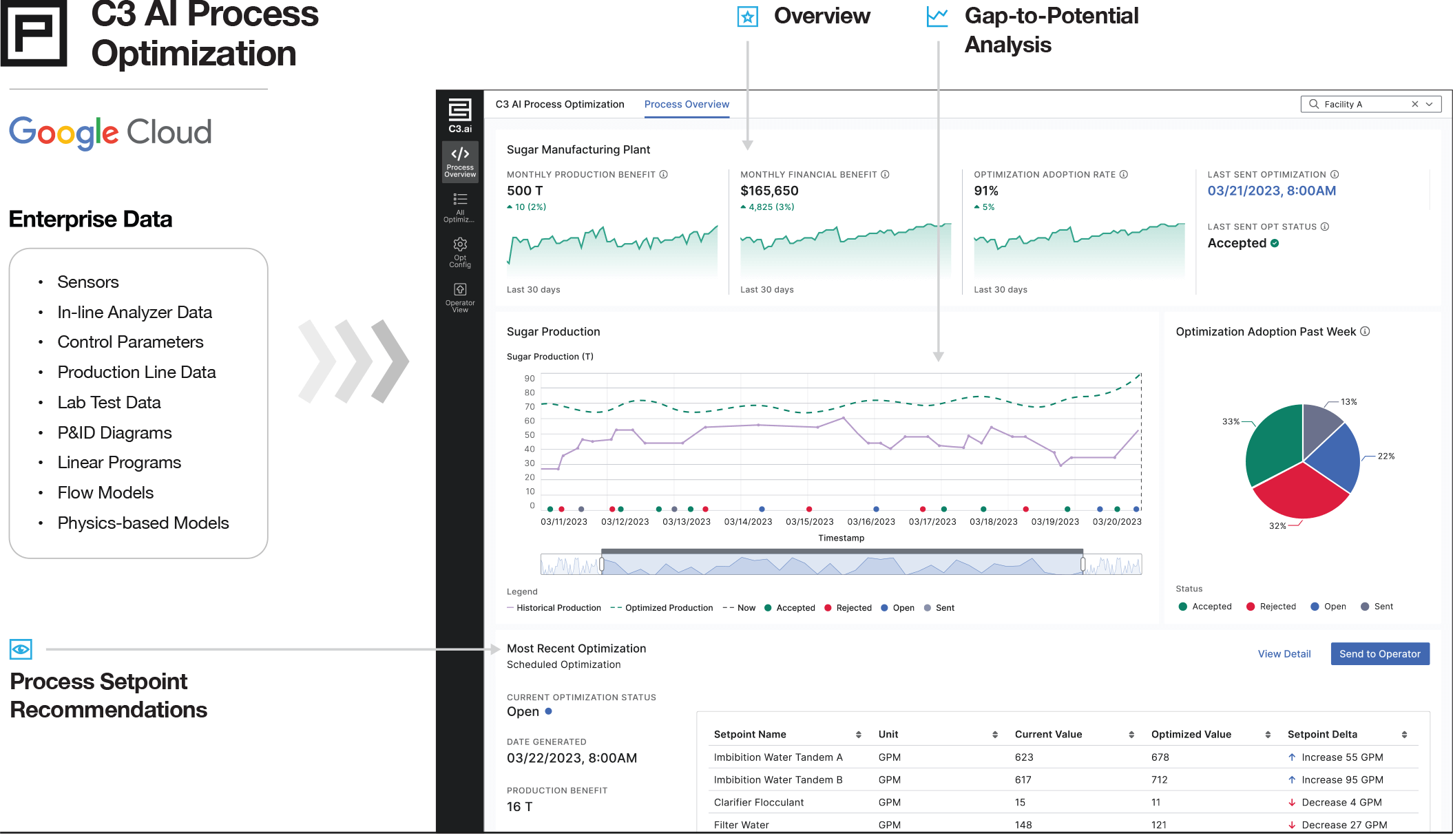

In 5 months, the company partnered with C3 AI to configure and deploy C3 AI Process Optimization to reduce sugar loss in byproducts before the next harvest season. The team started by ingesting, cleansing, and unifying 1 year of historical data, including sensor, lab measurement, and production line data.

The joint customer and C3 AI team configured and tested 16 ML models that predicted key variables in the manufacturing process, including yield, humidity, and transmittance. The team also generated metrics for over 100 constraints to ensure that mass balance, system, and historical bound constraints were captured by the optimizer.

The project team developed an optimizer that produces setpoint recommendations for 7 key control settings, accompanied by updates on more than 100 variables that are monitored to stay within designated upper and lower bounds. Now in production, the optimizer runs every 2-4 hours to provide engineers and operators with recommendations at a cadence that matches changing operating conditions. This allows users to continuously adjust setpoints and maximize yield.

About the Company

- 1+ million tons annual production of sugar and byproducts

- 4+ countries of operation

- 4 manufacturing plants worldwide

- 15,000+ employees

Project Objectives

- Increase frequency and impact of setpoint changes with timely recommendations

- Unify data from disparate sources collected at different frequencies to improve ML insights

- Enable engineers and operators to optimize yield as operating conditions change

- Configure the C3 AI Process Optimization application to interact with ML insights in a user friendly interface

Project Highlights

- 5 months from project kickoff to production-ready application

- 16 ML models configured and tested across a two-stage optimizer to maximize yield

- 1 year of historical data integrated, comprising 50 million rows of data from over 1000 sensors and lab measurements

- 250+ timeseries analytics developed for ML models and application user interface

- Configured C3 AI Process Optimization application user interface

Results

Solution Architecture