Learn how AI-powered asset performance solutions can increase overall equipment effectiveness by up to 5%, increase revenue, and decrease expenses

By Timothy Holtan, Senior AI Solution Director, C3 AI

Early asset performance management (APM) solutions from the 2000s promised increased asset reliability, decreased maintenance expenses, and increased profits — and industries driven by economies of scale including oil and gas, power generation, and commercial aviation were quick to adopt these new technologies. But soon organizations realized early asset performance management solutions fall short and don’t address the most business-critical ask: delivering predictive analytics rather than descriptive reporting. Now with AI-powered asset performance management solutions, enterprises can achieve accurate, powerful predictive maintenance that will reduce costs and improve efficiency.

Organizations Are Plagued by the Cost and Functional Limitations of Legacy APM Solutions

Early asset management systems focused on historical data — tracking lagging indicators like mean time between failures (MTBF), asset integrity, work orders, vibration, and functional failures. Monitoring services offered by original equipment manufacturers notified customers only after a failure has occurred and offered expedited replacement parts. They didn’t deliver what customers actually wanted: early warnings of equipment issues and guidance on how to avoid equipment shutdowns.

The addition of threshold-based analytics improved troubleshooting and provided the first version of asset performance solutions for asset operators. However, these analytics needed extensive manual data entry and input from subject matter experts. Customers found these analytics difficult to maintain at scale and did not adopt them broadly.

Nonetheless, over time, industrial organizations invested millions of dollars upgrading legacy computerized maintenance management (CMMS), enterprise asset management (EAM), and asset performance management (APM) solutions to alleviate the high costs of unplanned downtime and maintenance. Yet due to the limitations of these systems, non-productive time and high maintenance costs persisted.

Backwards Focused

Focused on displaying and explaining issues and damage that have already occurred

Limited Analysis

Limited to a few data types such as mean time between failure, vibration data, or lube oil analysis

Limited Modelling

Lacked flexibility to combine machine learning and engineering models or limited to specific models

Dependency on Experts

Relied on experts who are in short supply to generate recommendations for one- dimensional analyses

Despite investing heavily and setting ambitious goals for improved operations, industrial organizations suffered lost profits and high sunk costs as early analytical software solutions failed to deliver on promises. Today, industry seeks a new approach to deliver faster, more scalable, more accurate, and more actionable insights to increase asset utilization and availability. But new challenges have emerged in an already complex environment.

To deliver on these goals, a differentiated asset performance management solution must enable asset operators to overcome three core challenges:

- Aging Assets: Extended equipment lifecycle increase maintenance needs

- Declining Capital Expenditures: Decreased investments despite aging assets

- Shrinking Workforce: Decline in industrial workforce amidst rising expectations

Asset Management Challenge #1: Aging Assets

The industrial base of capital-intensive industries is aging. According to the Bureau of Economic Analysis, the average age of fixed assets has increased by an average of 21% across industries since 2015. Since older assets require more maintenance per year, shifting required maintenance from unplanned to planned alleviates the increased maintenance workload and costs.

Asset Management Challenge #2: Declining Capital Expenditures

Despite the aging asset base, capital expenditures continue to decrease. A study from NYU Stern School of Business shows that the capital expenditures in the U.S. oil & gas industry has decreased on an average of 55% from 2014 to 2023. As maintenance demands for aging assets continues to rise, new assets are either slow to arrive or unavailable to replace the aging installed base.

Asset Management Challenge #3: Shrinking Workforce

To add on to the challenge, the industrial workforce continues to shrink. The U.S. Bureau of Labor Statistics shows that the U.S. industrial workforce decreased by more than 40% since 2014. Industrial companies must do more with less and empower the existing workforce to become more efficient.

Industrial organizations require a new approach with an advanced asset performance management solution to address new asset management and profitability challenges.

Requirements for New AI-Powered Asset Performance Solutions

To stop the cycle of persisting asset management challenges, industrial managers need asset management solutions that can:

- Unify all data including sensors, work orders, reliability analyses, and equipment manuals together into a single source of truth.

- Predict functional failure early and be able to act quickly.

- Monitor all assets across rotating and fixed equipment and multi-unit operations.

- Scale quickly, from a single piece of equipment, to across one plant, to an entire enterprise.

The Benefits of AI-Powered Asset Performance Solutions

With AI-powered asset performance management solutions, industrial management can achieve the desired cost reduction and efficiency improvements by utilizing data and predictive models at unprecedented scale.

![]()

Integrate

- Time series data (e.g., AVEVA, Honeywell)

- Vibration analysis data (e.g., Bently Nevada, SKF)

- Laboratory data

- Work order data (e.g., SAP, IBM)

- P&ID diagrams (e.g., Dassault)

- Equipment data sheets (e.g., Worley Parson, Siemens)

- Reliability-centered analyses (e.g., Baker Hughes ARMS)

- Maintenance cost data (e.g., Oracle)

![]()

Predict

- Degradation rates of critical equipment based on near real-time performance

- Failure timing of critical equipment

- Characterization of incipient failure modes

- Recommended actions to address failure modes

- Process efficiency and yield gaps

- Process constraints

![]()

Optimize

- Control setpoints to maximize throughput and profitability

- Feedstock mixture to maximize yield

- Reaction rate to optimize chemical composition

- Multiple constraints across process steps to satisfy production schedule requirements

How Does C3 AI Provide AI-Powered Asset Performance Solutions?

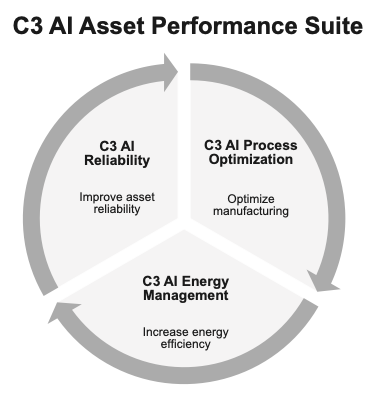

The C3 AI Asset Performance Suite is a portfolio of AI applications that helps industrial organizations improve uptime, productivity, and profitability. The suite has three major pillars: asset reliability, process optimization, and energy efficiency.

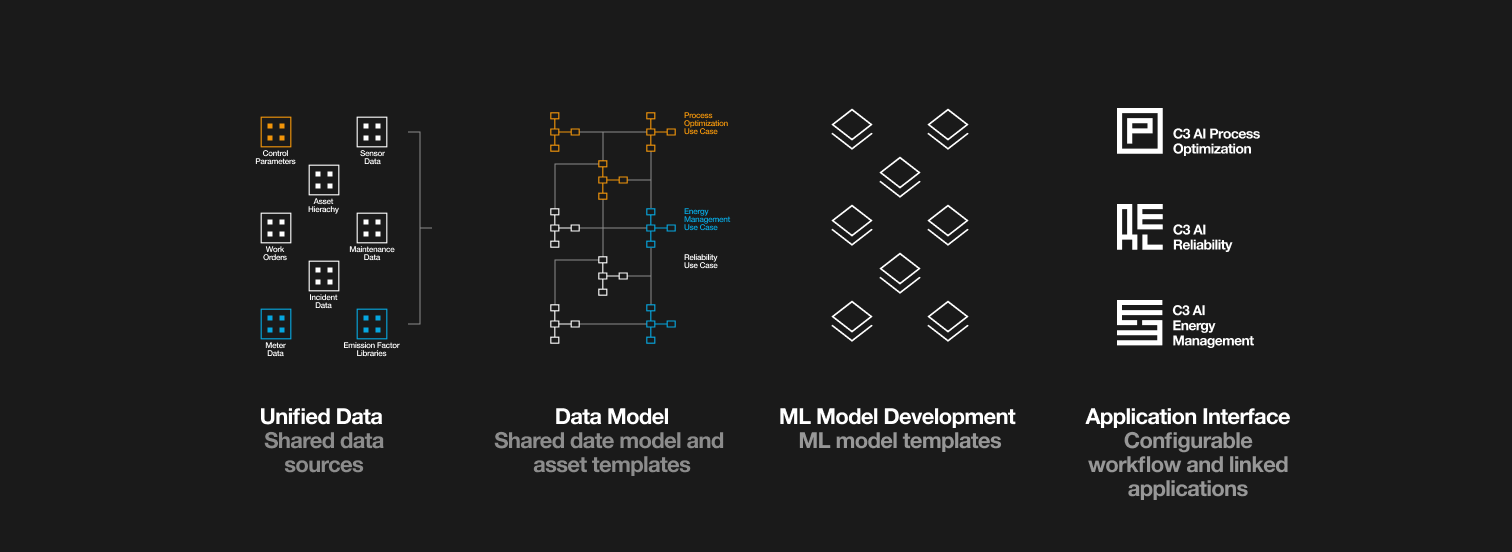

The C3 AI Asset Performance Suite is a next-generation asset performance management solution that enables enterprises to:

- Unify all data from disparate sources including data historians, failure mode libraries, work orders, utility bills, and operating manuals. Instead of having to navigate to and gather data from each of these sources individually, enterprises can now combine all this data into a single data model for predictive analysis.

- Predict risks early and take action using robust evidence packages for AI alerts and recommended actions. Rather than focused on explaining issues that have happened already, enterprises can look ahead to impending risks with accurate predictions.

- Monitor all assets across equipment types and multi-unit operations with equipment-agnostic machine learning models and flexible templates. Enterprises are no longer confined by specific models designed for specific types of equipment and can use a flexible approach to enable predictive monitoring for all assets and operations.

- Scale and operationalize AI quickly with underlying AI platform capabilities. Organizations can move shift away from proof of concepts and operationalize AI at scale by deploying configurable AI applications for different parts of the business.

Improve Asset Health and Availability with C3 AI Reliability

C3 AI Reliability is an AI-enabled predictive maintenance application that helps organizations improve uptime and productivity. The application integrates disparate data sources, including timeseries data, piping & instrumentation diagrams, lab data, and equipment data sheets into a unified data model.

C3 AI Reliability applies multi-variate machine learning models on top of the integrated data to predict failures before traditional alarms. To help users quickly gain context of the alert, the application provides an evidence package of values and charts to explain and to support the failure predictions. The application also predicts the likely failure modes and recommends actions to prevent equipment failures to accelerate root cause analyses.

To help operations and engineers take preventative action, the application provides a case management workflow that allows analysts to escalate predictions to subject matter experts for validation, and for experts to create work orders and assign a maintenance worker to carry out the AI-recommended actions.

Georgia-Pacific, one of the world’s leading makers of tissue, pulp, packaging and building products, has improved overall equipment effectiveness (OEE) by up to 5% and eliminated hundreds of hours of unplanned downtime by using C3 AI Reliability to monitor over 60 critical manufacturing assets. Prior to partnering with C3 AI, Georgia-Pacific recognized the limitations of their existing platforms for modeling and data integration needs of complex assets. With C3 AI Reliability, the company has implemented a holistic approach to monitoring complex assets and focusing maintenance activities on the most critical risks.

Maximize Yield and Efficiency with C3 AI Process Optimization

C3 AI Process Optimization helps organizations improve production yield, costs, and energy efficiency. The application integrates disparate data sources including process timeseries data, lab data, raw material costs, and finished product specifications, into a unified data model.

C3 AI Process Optimization applies engineering and machine learning models on top of the integrated data to predict process constraints and heat and material balance issues. The optimization model incorporates key variables, associated constraints and computational expressions, and a configurable objective function, such as maximized profitability or minimize cost per production unit. To help process engineers drive process improvements, the application recommends the optimal process settings and the setting changes needed to meet the optimization objective. C3 AI Process Optimization empowers process engineers and operators to collaborate closely to expand historical operating envelopes.

To improve yield, one leading global pharmaceutical company that produces vaccines, oncology, and general medicines uses C3 AI Process Optimization. Prior to partnering with C3 AI, process engineers struggled with receiving yield insights late in the manufacturing process, which limited their ability to take action to improve yield. By deploying C3 AI Process Optimization, the company enabled earlier and more accurate yield insights, allowing the biologics facility to increase yield by 1.5% and reduce time to insight by 70%. When deployed at scale across five facilities, the company can realize up to $10 million in annual economic value from increased production.

Increase Energy Efficiency with C3 AI Energy Management

C3 AI Energy Management helps organizations reduce energy costs and improve the efficiency of utilities, including energy, water use, and waste. The application integrates utility data and production data from disparate sources such as equipment and line sensors, historians, meters, utility bills, and facility schedules, into a unified data model.

C3 AI Energy Management applies machine learning on top of the unified data to forecast energy consumption at the organizational, facility, and equipment level. To help organizations manage energy costs in near real-time, the application provides continuous monitoring of energy use and alerts users when consumption exceeds the expected forecasts. C3 AI Energy Management helps facilities proactively identify and implement improvements to reduce utility consumption and costs.

A leading petrochemical company is a top producer of high-quality ethylene, polyethylene, and 1-hexene products. Prior to partnering with C3 AI, the company relied on its sustainability team to calculate energy consumption and emissions through a manual and time-consuming process. However, due to the manual calculation process, the sustainability and operations team lacked the real-time and equipment-level consumption analytics to drive improvements. By deploying C3 AI Energy Management to monitor 14 equipment units in an ethylene plant, the company has automated consumption and emissions calculations and enabled equipment-level insights to help sustainability and plant managers identify and prioritize maintenance and capital cost initiatives to maximize energy cost savings and emissions. With a scaled-out deployment across two facilities, the company can save up to $3.2 million in energy costs per year.

C3 AI Asset Performance Suite helps organizations improve asset reliability, optimize manufacturing processes, and increase energy efficiency.

The Value of a Platform Approach for Asset Performance Management

Underpinning the C3 AI Asset Performance applications is the C3 AI Platform. The C3 AI Platform offers three key benefits — the ability to integrate all enterprise data, the ability to manage machine learning models at scale, and the ability to deploy C3 AI applications as fully integrated solutions.

![]()

Flexible Data Model

Integrate all enterprise data easily as the company grow and evolve over time

![]()

Scalable Model Management

Utilize high-performing machine learning models at scale across operations

![]()

Integrated Solutions

Leverage synergy between fully integrated asset performance solutions

First, the C3 AI Platform enables flexible application data models. The C3 AI Platform uses a patented model-driven architecture to offer predefined, fit-for-purpose data models for each application. This capability accelerates application configuration and scale-out, allowing customers to rapidly capture value from their existing data.

Second, the C3 AI Platform enables machine learning models to be applied and managed at scale. To monitor asset health at scale and across asset classes, organizations need to deploy millions of machine learning models generating predictions across all operations. On the C3 AI Platform, data scientists can build models using model templates, monitor model performance, test competing models, and deploy the highest-performing models into production in a few clicks.

Finally, the C3 AI Platform allows C3 AI Asset Performance Suite applications to work together seamlessly. Using the model-driven architecture, C3 AI applications can reuse common data sources for different AI use cases, reducing the incremental effort required to scale and operationalize AI across the enterprise. An enterprise using C3 AI Reliability to reduce unplanned equipment failures can add C3 AI Process Optimization on top of the same processes to augment standard operating envelopes based on increased asset availability and reliability, and add C3 AI Energy Management to then minimize energy costs and reduce carbon emissions.

C3 AI provides a platform approach for asset performance management to unlock increased flexibility, scalability, and value for industrial organizations.

Get Started with C3 AI Today

Deploy AI-powered asset performance solutions and reap high, consistent financial returns. Learn more about C3 AI Asset Performance Suite and reach out today to get started.

C3 AI Asset Performance Suite

About the Author

Timothy Holtan is a Senior AI Solution Director at C3 AI. Drawing on a career in chemical engineering, machine learning, and finance, Timothy solves the most challenging business problems. Prior to C3 AI, Timothy served as a process engineer at Mobil Oil, an investment banker at A.G. Edwards, a presales leader at SmartSignal, a monitoring and diagnostics services leader at GE, and a principal software architect at Baker Hughes. Timothy earned a B.S. in Chemical Engineering from the University of Illinois Urbana-Champaign and an MBA in Analytic Finance from the University of Chicago Booth School of Business.