Pharmaceutical Company Increases Yield in Batch Manufacturing with AI Insights

Download the PDF to read the full story - Download

Challenges

A global pharmaceutical company is a leading producer of vaccines, oncology, and general medicines, with operations in over 60 countries worldwide. The company was challenged with suboptimal yield and sought a solution to address the problem.

Prior to engaging C3 AI, the company made an executive commitment to leverage AI and machine learning (ML) in every facet of its business. Internal teams had built offline data science experiments to help optimize yield, but struggled to deploy them in a usable format for manufacturing production. With the in-house solution, yield insights were sent to process engineers late in the batch process, hindering their ability to take action with the information. Engineers also spent 3-5 hours on manual data analysis to understand historical batch performance. To overcome these challenges, the company needed real-time yield prediction and optimization, as well as quick access to information from historical data and operating documents.

Approach

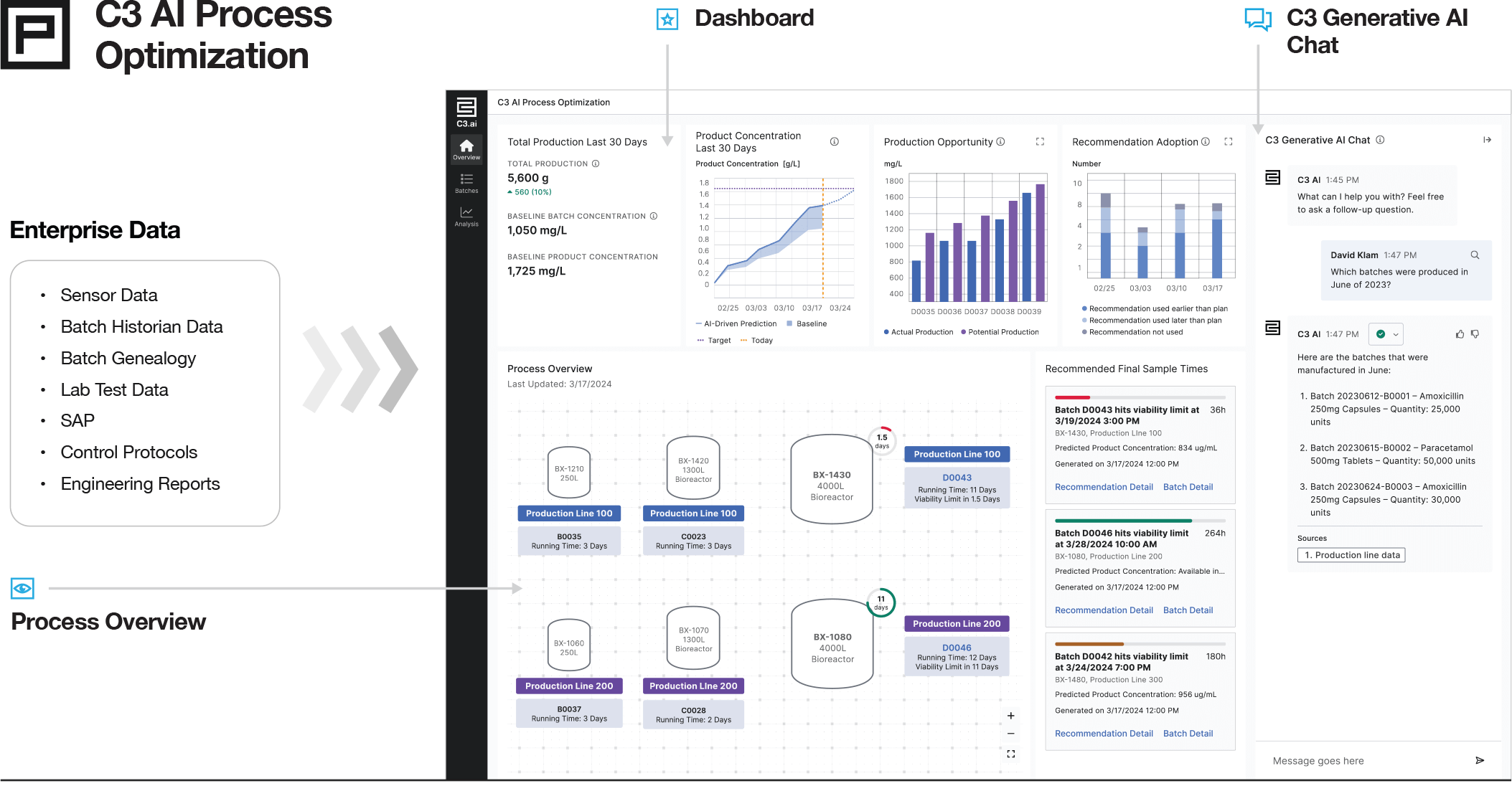

In 5 months, C3 AI partnered with the company to configure and deploy C3 AI Process Optimization with generative AI search and chat for a biologics drug substance manufacturing facility. The team started by virtualizing, normalizing, and unifying 4 years of historical batch data from 3 different systems, including DeltaV batch historian records, IP21 time-series sensor readings, SAP batch genealogy data, and lab sample readings.

The joint team configured and tested 9 ML models that predicted key variables in determining batch harvest readiness. These models predict when the batch harvest viability limit will be reached 3 days into the batch, providing engineers with insights 7 days earlier and enabling a 1.5% improvement in annual yield. Predictions are routed to existing harvest scheduling processes through an in-app workflow to optimize the harvest schedule.

C3 AI Process Optimization provided batch analysis tools that allow engineers to monitor the process in near real-time and easily draw insights. Integrated generative AI search capabilities took this one step further, allowing engineers to ask over 3,000 simple questions about batch data and operating procedures with 96% accuracy rate in responses. In minutes, users can now gain insights that previously took hours.

About the Company

- $20+ billion in annual revenue

- 60+ countries of operation

- 30+ manufacturing plants worldwide

- 60,000+ employees

Project Objectives

- Generate timely batch predictions so engineers can act early to maximize yield

- Accelerate time-to-insight with generative AI search for structured and unstructured data

- Unify data from siloed systems to provide operators comprehensive ML insights on yield performance

- Configure C3 AI Process Optimization to offer ML insights in an intuitive user interface

Project Highlights

- 5 months from project kickoff to production-ready application

- 2+ years of historical batch data integrated from 3 siloed systems and 1000+ pages of documents

- 9 ML models configured and tested, with 60+ underlying features, to track and visualize batch yield

- Embedded generative AI search and chat powered by C3 Generative AI

- 3000+ structured questions that process engineers can query against operational documents and historical batch data

- Configured C3 AI Process Optimization application user interface

Results

Solution Architecture