Enterprise AI for Operating Efficiency

Challenges

A leading global oil and gas company operates more than 10 deepwater upstream platforms, which account for approximately 20% of the company’s annual oil and gas production worldwide. Operating in remote deepwater upstream platforms requires the continuous use of equipment that consume fuel and emit greenhouse gases (GHGs). As a responsible industry leader, the company acknowledges the need to reduce GHG emissions and has implemented various strategies to minimize its environmental impact while maintaining operational efficiency.

The company’s previous methods only allowed for low-resolution emissions monitoring and led to several challenges when working to reduce emissions, including the inability to proactively address operating performance issues and a limited and inconsistent view of equipment efficiency and evaluations.

Approach

Over 16 weeks, C3 AI configured the C3 AI Energy Management application for two critical upstream platforms of the oil and gas producer. The joint C3 AI and customer team built an integrated, unified federated data image comprised of over half a billion rows of data, allowing the company to deploy and operate the C3 AI Energy Management application on up-to-date data extracted from all relevant sources.

The team employed probabilistic supervised learning to establish GHG emissions and operating performance baselines for each equipment. Finally, the joint team designed and implemented a multi-screen user interface that streamlines high-resolution GHG emission monitoring and provides transparency across equipment, platforms, and the entire enterprise. The user interface effortlessly supports benchmarking equipment operations and sustainability metrics across platforms and the entire organization, making it an essential enterprise AI application for a modern and environmentally-conscious business.

This innovative approach has several benefits including:

- Streamlining equipment performance benchmarking, allowing users to effortlessly assess if their current performance is superior, inferior, or in line with the expected baseline.

- Providing insights into how the equipment is performing in comparison to its equipment cohort and historical performance expectation.

- Calculating potential GHG emissions savings by comparing the actual performance with the predicted baseline, unveiling actionable emissions reduction opportunities.

Project Objectives

- Integrate and unify four years of data from five data sources with more than 500M timeseries data points, including sensor data, hierarchy data, event data, emission factors, and weather data.

- Implement machine learning algorithms to establish operating performance and GHG emission baseline performance metrics for 16 equipment across two platforms.

- Configure the C3 AI Energy Management user interface, exposing AI insights and unified analytics to end users.

- Provide near-real-time, high-resolution GHG emissions monitoring at equipment, platform, and enterprise level.

About the Company

- $350+ billion annual revenue in 2022

- 10+ deepwater upstream platforms worldwide that significantly contribute to the company’s annual production levels

- 1.5+ million barrels of oil equivalent per day

- 90,000+ employees

Project Highlights

- 16 GHG emitting equipment assessed across two offshore platforms

- Five years of historical data integrated, comprised of 500 million rows from three enterprise IT systems and two third-party systems

- Configured an extensible data model with 15+ C3 AI logical objects

- Developed 300+ time series analytics for machine learning models and application UI

- Configured and tested 26+ machine learning models to baseline equipment performance and identify anomalies and regime shifts

Results

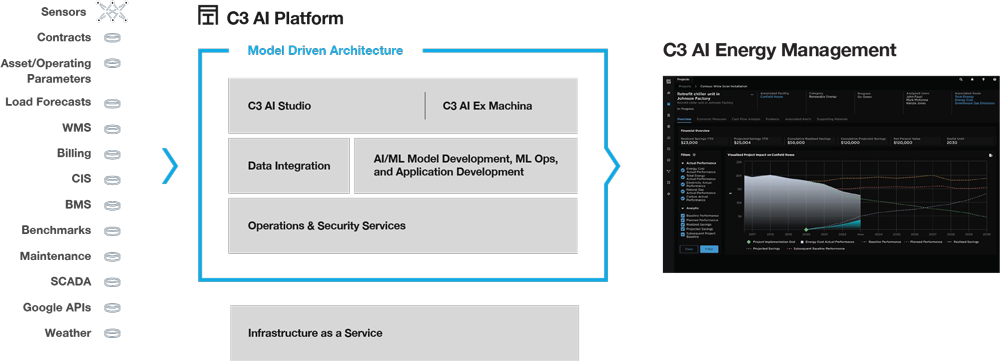

Solution Architecture

Benefits

With C3 AI Energy Management, the company:

- Identified 880 CO2e tonnes of annual savings from actionable GHG emission reduction opportunities.

- Detected 10 operating regime shifts (i.e., changes in the equipment operating conditions) driving higher GHG emissions.

- Uncovered 30 GHG emission operating anomalies driving higher emissions.

Moving forward, the company can continue to:

- Facilitate equipment project prioritization by analyzing the gap between current performance and potential capabilities.

- Monitor high-resolution GHG emissions at equipment, platform, and enterprise levels in near real time.

- Benchmark equipment performance across various operating platforms and throughout the entire enterprise.

- Examine the primary factors influencing equipment performance and emissions deterioration through a comprehensive evidence package.