Steel Company Transforms Value Chain with AI

Download the PDF to read full story – Download

Challenges

Before implementing C3 AI applications—including C3 AI Demand Planning, C3 AI Raw Materials Optimization, C3 AI Production Schedule Optimization, and C3 Generative AI for Detailing—the company faced increasing pressure to optimize supply chain performance and enhance decision-making across its value chain. The raw materials unit struggled with short forecasting horizons, price volatility, and manual data consolidation, leading to increased inventory costs and supply chain risks. In the steel making unit, production scheduling was managed manually through spreadsheets, taking up to five days and limiting responsiveness to demand changes, resulting in lower yield, excess inventory, and frequent production delays. Meanwhile, the steel products unit relied on labor-intensive detailing processes that required up to 200 hours per job, resulting in delays, errors, and increased labor costs. These challenges, driven by fragmented data and manual workflows, hindered agility and responsiveness across the operations.

Approach

Recognizing the need for advanced digital capabilities, the company partnered with C3 AI to deploy four scalable, AI-driven applications across its value chain over a two-year period. The company unified 15 disparate data sources with C3 AI Demand Planning to generate accurate 20-week forecasts, improving forecast accuracy by 13% and streamlining raw material inventory management worth $200 million. Building on this foundation, C3 AI Raw Materials Optimization analyzed over five years of historical data and configured an optimizer with 50+ parameters to determine optimal mix percentages, identifying a 1% cost reduction opportunity. In the steel making unit, C3 AI Production Schedule Optimization automated caster scheduling, reducing planning time by 98% and increasing scheduled yield by 0.6%. Lastly, the company configured C3 Generative AI for Detailing for its steel products unit to streamline the detailing process, automating information retrieval and achieving over 87% accuracy, significantly reducing manual effort. With these C3 AI applications, the company optimized processes with AI-powered workflows, enhancing operational agility and responsiveness across the organization.

About the Company

- $35+ billion annual revenue in 2023

- 35+ million tons of steel produced

- 30+ steel mills

- 20,000+ employees

Project Objectives

- Increase demand forecast accuracy and improve raw material inventory planning with C3 AI Demand Planning and C3 AI Raw Materials Optimization

- Optimize caster production scheduling with C3 AI Production Schedule Optimization

- Reduce detailing and checking time with C3 Generative AI for Detailing

Project Highlights

- C3 AI Demand Planning

- 15 disparate data sources unified

- 23 machine learning models configured to provide 20-week order forecasting horizon

- C3 AI Raw Materials Optimization

- 5+ years of historical data analyzed

- Optimizer configured with 50+ parameters to help plan raw material consumption

- C3 AI Production Schedule Optimization

- 10 disparate data sources unified

- AI optimization models configured to balance production constraints and parameters

- C3 Generative AI for Detailing

- 7 data elements integrated, including structured and unstructured data sources spanning 50+ tables and 2 unstructured document formats

- 200-hour manual process automated to reduce time

Results

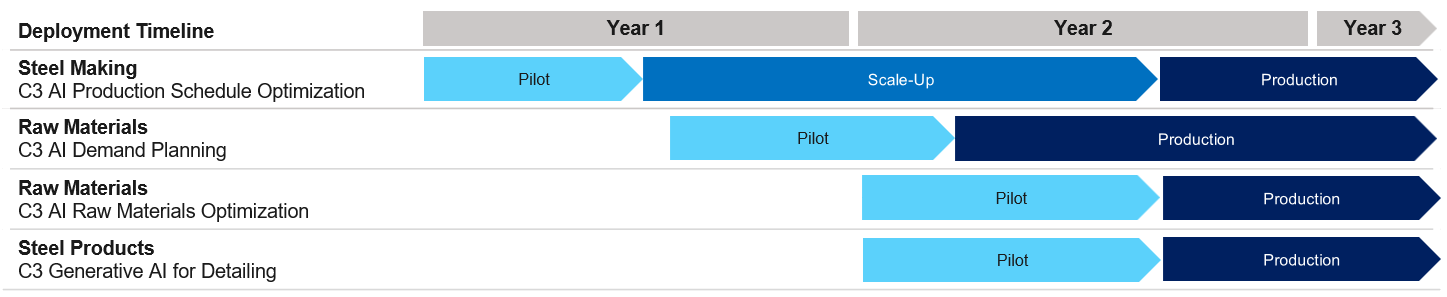

Deployment Timeline

Solution Architecture