Dynamic Production

Optimization

Enhance Agility, Respond Rapidly, and Maximize Production

C3 AI Production Schedule Optimization helps production schedulers improve on-time completion rates, increase resource utilization, and alleviate bottlenecks. Schedulers can create near-term schedules and long-term plans with flexible scenario analysis and integrate in real-time with production systems to maximize schedule performance.

Explore how C3 AI Production Schedule Optimization unifies disparate data such as job schedule data, on-hand delivery, and resource availability, and applies best-in-class optimization techniques to enhance production agility.

The C3 AI Difference

Use all available data and AI-powered scheduling to maximize manufacturing performance.

-

High Value

Improve production throughput by

20%

-

Optimized Scheduling

Increase production scheduling efficiency by

50X

-

Maximum Productivity

Increase production capacity utilization up to

100%

-

Fast Results

Achieve results as early as

4wks

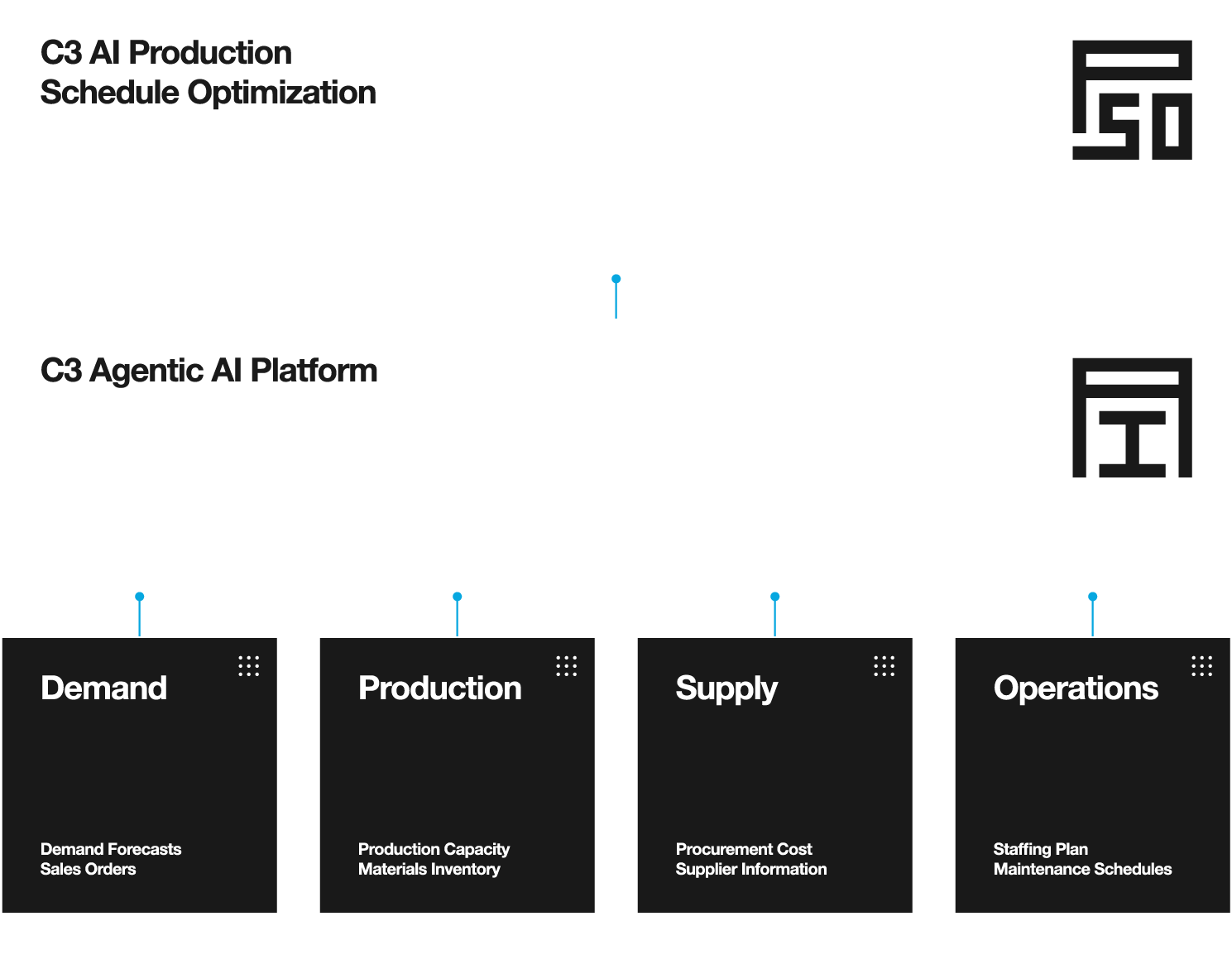

Leverage All Your Data

Powered by the C3 Agentic AI Platform, unify data and run scenarios across various sources such as manufacturing processes, demand forecasts, sales orders, and inventory data to create a digital twin of production operations.

Scale across facilities and to thousands of constraints with ease.

Optimize with Generative AI

Access and interact with operational expertise and AI insights through an embedded search and natural language chat interface.

Optimize Performance with Advanced AI

Leverage AI optimization that accounts for thousands of operating constraints for both short-term scheduling and long-term strategic planning. Adapt to dynamic conditions with flexible schedule horizon and granularity.

Accelerate Decision-Making with AI-Driven Scenarios

Empower strategic decision-making with scenario analysis, rapidly accounting for changes in demand, labor, and materials, and accelerate the entire scheduling process by reducing time-to-adapt to changing conditions with real-time optimization.

Maximize Profitability with AI

Discover how C3 AI Production Schedule Optimization can help your organization fulfill customer demand and improve costs, on-time delivery, and resource utilization. Get in touch today.

Thank you for your interest in C3 AI Production Schedule Optimization.

We have received your request and will be in touch with you shortly.