By Yimin Liu, Lead Data Scientist, C3 AI, Jianchen Yang, Lead Data Scientist, C3 AI, Stefano Zavagli, Senior Data Scientist, C3 AI, Minnie Tan, Senior Data Scientist, C3 AI, Justin Kendig, Principal Product Manager, C3 AI, and Mehdi Maasoumy, Vice President, Data Science, C3 AI

Global supply chains have never been more volatile. From sudden demand shifts to unpredictable supplier lead times, disruptions have become the rule rather than the exception. Inventory managers are under pressure to keep shelves stocked without tying up capital in excess goods. Too much inventory leads to high costs and waste; too little creates shortages, missed service levels, and frustrated customers.

C3 AI Inventory Optimization is advanced AI inventory management software designed to solve this exact problem. By leveraging simulation, advanced optimization techniques, and dynamic reorder recommendations, it enables businesses to right-size inventory across products, locations, and suppliers — even in the face of constant uncertainty.

The Balancing Act of Supply Chain Logistics

The difficulty of inventory management lies in the trade-offs. Carrying excess stock provides a cushion. It reduces the likelihood of stockouts, smooths over unexpected demand spikes, and keeps customers satisfied. Yet it also comes with the cost of tying up working capital, inflating warehousing expenses, and increasing the risk of products going obsolete or expiring. Conversely, running lean inventories keeps capital requirements low, reduces exposure to waste, and frees resources for other priorities. But lean operations heighten the risk of shortages, delayed shipments, and dissatisfied customers.

Even with sophisticated forecasting tools, planners face uncertainty. No matter how robust the forecasts or how careful the planning, reality often causes disruption on all sides. That volatility and expected disruption is why most businesses maintain safety stock: an extra buffer of inventory that absorbs shocks and helps planners keep service levels consistent. But the challenge then becomes knowing how much safety stock to hold.

Safety stock is meant to cover forecast errors, supplier delays, or sudden surges in demand. When calculated appropriately, it ensures service levels remain high without overburdening the business with excessive carrying costs. The problem is that static rules and textbook formulas are rarely accurate enough to capture the complexity of today’s supply chains. What is required is a more dynamic, data-driven approach.

A Smarter Way Forward with Enterprise AI

C3 AI Inventory Optimization takes the guesswork out of inventory planning. The AI application calculates the appropriate level of safety stock, reorder points, and min-max levels for each product and location. These variables — known collectively as reorder parameters — form the backbone of inventory policy. Instead of relying on one-time settings, the solution evaluates forecast error, lead-time variability, and service-level targets on an ongoing basis. It recommends dynamic adjustments that respond to the real-world fluctuations in demand and supply.

In environments where reactive planning strategies such as min-max or reorder point planning are better suited, C3 AI Inventory Optimization enhances those too. By dynamically adjusting order triggers based on actual consumption and supply conditions, the system ensures organizations maintain both agility and resilience.

At the heart of C3 AI Inventory Optimization is a simulation-driven approach. It begins by modeling how inventory levels evolve over time, incorporating the real-world dynamics of demand fluctuations, supplier reliability, and planning rules. This simulation mirrors the day-to-day decision-making process of inventory planners as they review balances, incoming orders, forecasts, and lead times. Additionally, the algorithms continuously adapt to the complex, evolving landscape of supply and demand by learning from the most recent variations.

Once the simulation reflects actual conditions, optimization techniques are applied. These algorithms test countless combinations of reorder parameters to find the ones that minimize total costs while still achieving service-level goals. To account for uncertainty, the system employs Monte Carlo simulations, which run hundreds of scenarios across varying demand and supply patterns. The result is a range of possible outcomes, from best case to worst case, that provide a more robust basis for decision making.

C3 AI Inventory Optimization in Action

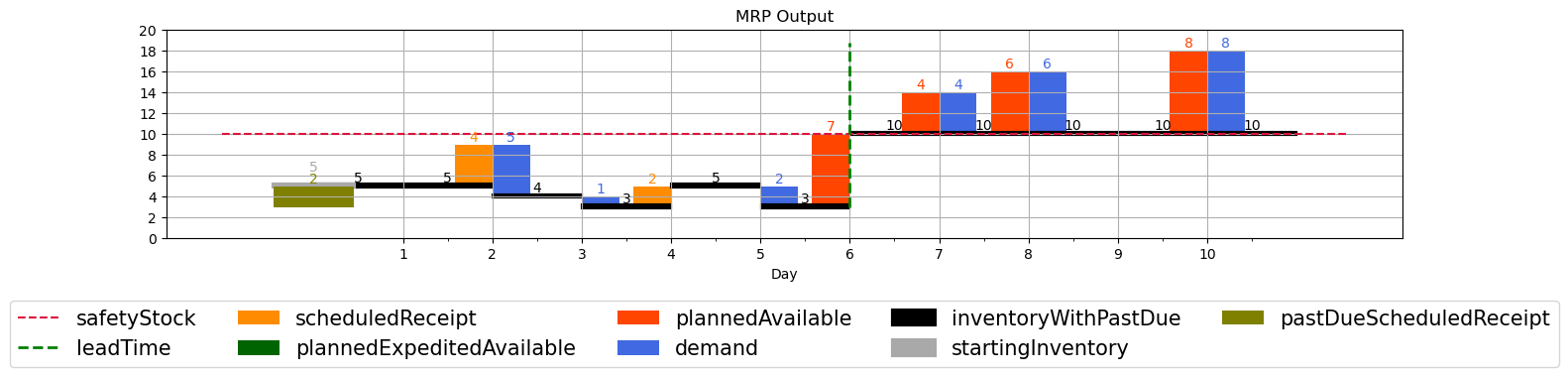

Consider an inventory planner responsible for a single SKU. She sees that twenty units are on hand and five more are on order. The forecast projects consumption of four units per week, and the planning lead time is five weeks. By the end of week five, only five units will remain. If the business wants to maintain a safety stock of ten units, the inventory will already fall short. To remain above the threshold, the planner would need to place a replenishment order immediately, bringing stock back up to the desired level.

This is the basic logic of material requirements planning, or MRP, which most ERP systems automate. In reality, though, conditions rarely remain stable. Consumption may exceed forecasts, orders may be delayed, or promotions may push demand higher than expected. In such unstable situations, planners often scramble, placing rush orders at higher costs to prevent stockouts.

Figure 1. MRP output aligned with starting inventory, demand forecasts, lead times, and scheduled receipts, keeping stock above the safety threshold.

C3 AI Inventory Optimization takes this manual process and scales it. By simulating thousands of such scenarios and optimizing reorder parameters accordingly, it equips organizations with a data-driven framework that anticipates variability instead of simply reacting to it.

The approach begins with implementing AI in inventory simulation, which mirrors real-world planning behavior with historical consumption, forecasts, lead times, and supplier performance. It then layers on optimization, balancing the cost of holding excess stock against the penalties of shortages. Finally, it validates strategies through back-testing, replaying them against historical conditions to ensure that the optimized policies work in practice, not just in theory.

To better understand how C3 AI Inventory Optimization delivers value, consider a customer case where persistent inefficiencies in inventory planning were creating both excess costs and service risks. Inventory levels were consistently above what was required, locking up capital, while forecasts routinely failed to capture short-term swings in demand. At the same time, supplier lead times fluctuated by as much as two weeks, compounding the problem and leading to stockouts despite carrying excess stock.

The following figures trace how these challenges were uncovered and addressed. They begin by examining the historical behavior of inventory, forecasts, and supply performance, then show how simulation and optimization techniques can reshape policies. Finally, they demonstrate how the optimized strategy performs under real-world conditions, proving that businesses can simultaneously cut costs and strengthen resilience.

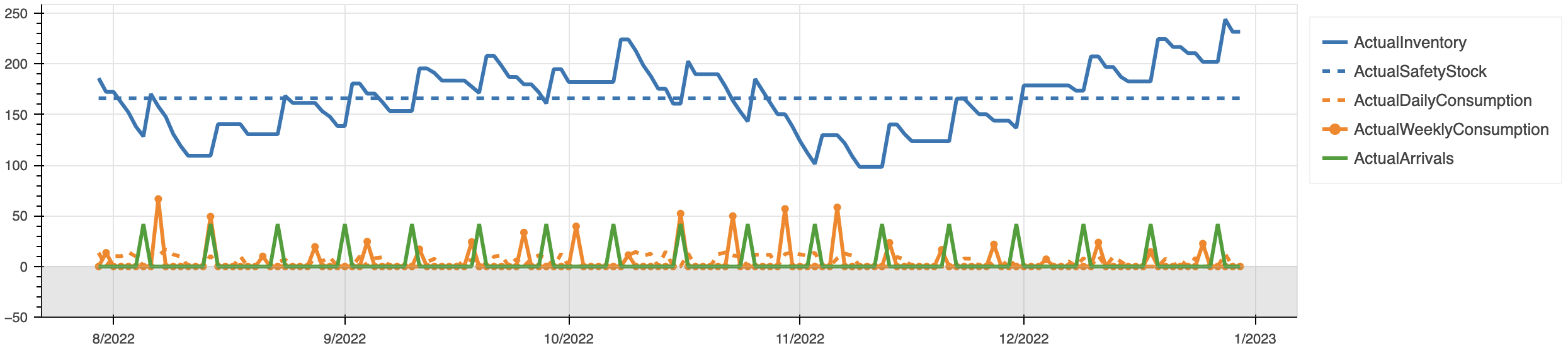

The analysis begins with a view of historical inventory and material movements. As Figure 2 shows, inventory levels were generally high but also fluctuated significantly, underscoring the difficulty of keeping stock aligned with actual consumption patterns. The solid blue line shows actual inventory levels over time, while the dashed blue line marks the designated safety stock threshold. Orange markers and green bars highlight daily and weekly consumption, illustrating fluctuations in demand, while orange bars indicate incoming inventory arrivals and their frequency. Taken together, the chart shows that inventory levels are generally high but vary significantly, underscoring the difficulty of aligning stock with both forecasted demand and actual usage.

Figure 2. Historical inventory and material movements for a single SKU.

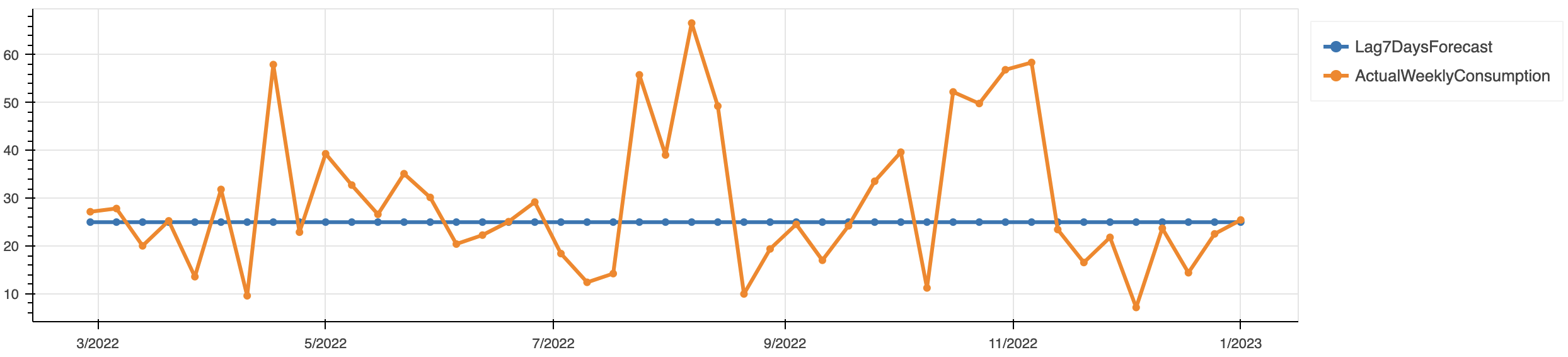

This challenge becomes clearer in Figure 3, which compares the demand forecast against actual usage. The forecast captured an average trend but consistently missed short-term peaks and dips, leaving planners blind to sudden demand surges or slowdowns. The blue line (“Lag7DaysForecast”) shows predicted demand one week in advance, while the orange line (“ActualWeeklyConsumption”) reflects true usage. Although the forecast captures an average demand level, it consistently misses short-term peaks and dips. These gaps highlight the risks of relying on static forecasts: inventory managers may carry excess stock when demand is low or face stockouts when demand unexpectedly spikes.

Figure 3. Historical demand forecast versus actual consumption.

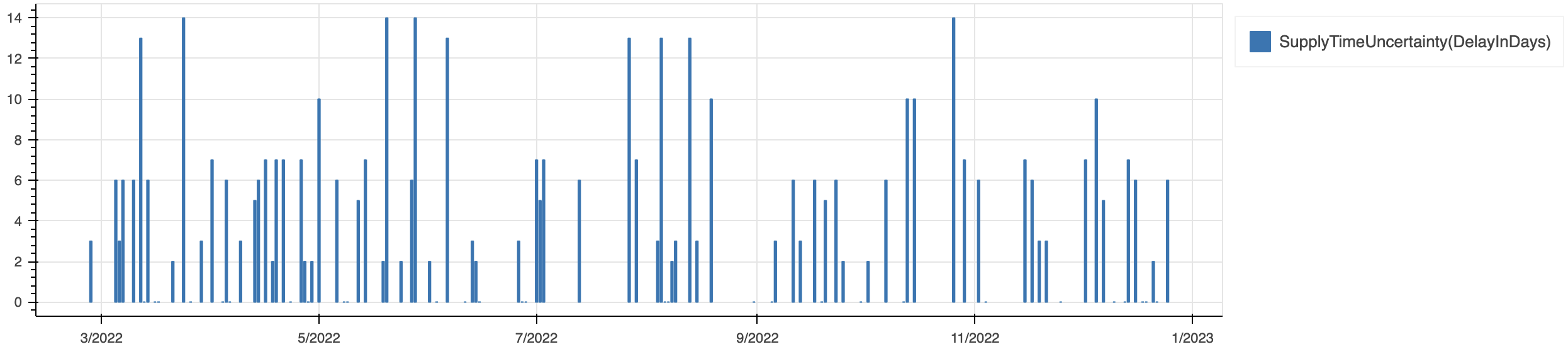

The problem was further compounded by supplier variability. Figure 4 illustrates how delivery times often deviated from plan by as much as two weeks, meaning that even if forecasts had been accurate, late arrivals could still trigger shortages. The chart shows how actual delivery times for purchase orders frequently deviated from planned schedules, in some cases by up to 14 days. These recurring delays make inventory planning far more difficult, especially when combined with inaccurate demand forecasts. The pattern highlights a critical challenge for supply chains: supplier uncertainty is not an exception but a regular feature and failing to account for it increases the risk of stockouts and costly last-minute interventions.

Figure 4. Historical variability in supplier lead times.

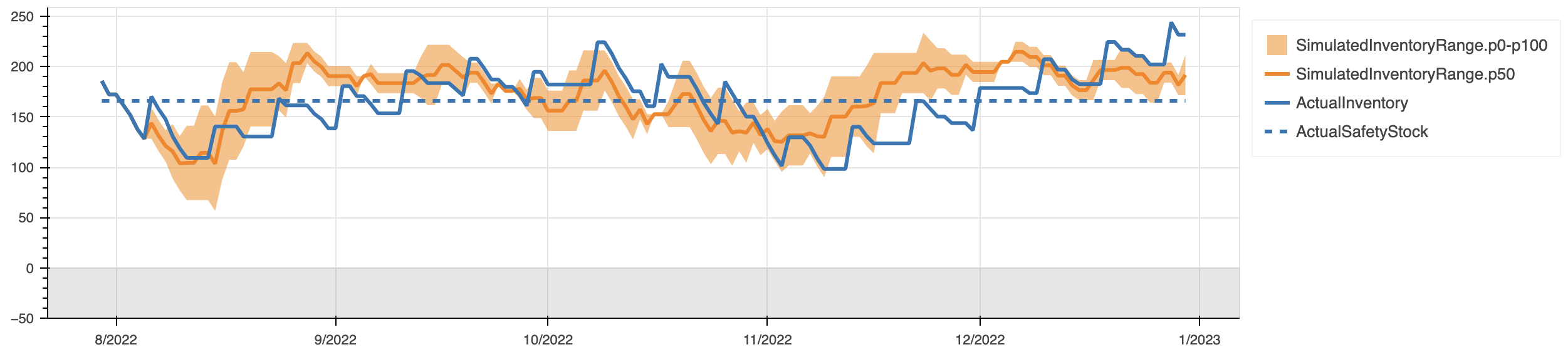

To address this combined uncertainty, C3 AI Inventory Optimization runs Monte Carlo simulations. Figure 5 shows how hundreds of simulated demand and supply scenarios reveal a range of possible outcomes, giving planners a probabilistic view of risk rather than a single deterministic forecast. The shaded bands show best-case to worst-case outcomes, while the median line reflects the most likely inventory path. This stochastic view equips planners to anticipate uncertainty rather than react to it, ensuring reorder parameters are set to minimize stockouts and excess holding costs. The result is a more resilient and cost-efficient inventory strategy that adapts to real-world volatility.

Figure 5. Monte Carlo simulation of inventory outcomes.

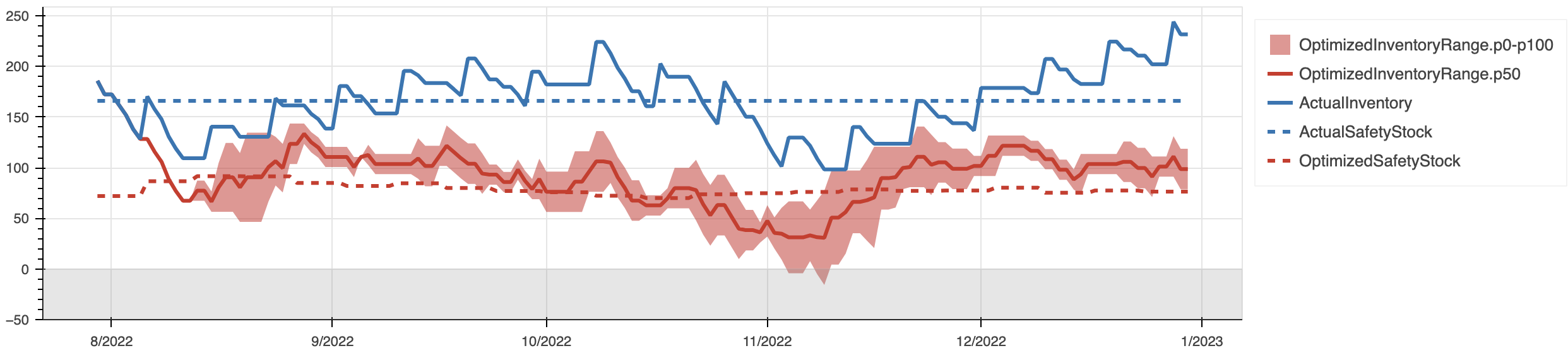

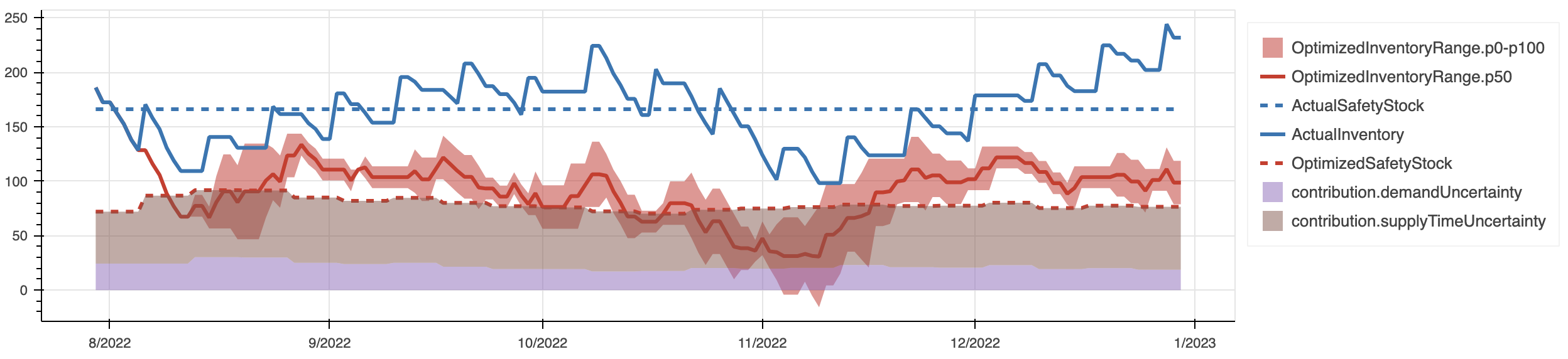

The solution then tests optimized reorder policies against history to prove their effectiveness. As shown in Figure 6, back-testing demonstrates that the optimized strategy, shown as the red dashed line for safety stock and the red shaded band for inventory range, would have kept service levels steady while lowering on-hand stock, reducing costs without sacrificing resilience. This reduced inventory band highlights how C3 AI Inventory Optimization lowers carrying costs without compromising resilience, proving that AI in inventory management delivers measurable efficiency gains in practice.

Figure 6. Back-testing optimized inventory policies.

Finally, Figure 7 provides insight into the relative contributions of demand and supply uncertainty. By breaking down how each source drives safety stock requirements, the model ensures that policies buffer against both sides of volatility, creating a balanced and robust approach to inventory planning. The purple and gray shaded areas in the figure show how much variability in demand and supply lead times each contribute to the optimal safety stock level. By separating these sources of risk, the model reveals how both sides of the equation must be considered together to avoid blind spots. This balanced approach ensures reorder parameters are calibrated to buffer against the most significant drivers of volatility, creating more resilient and cost-effective inventory policies.

Figure 7. Breaking down demand and supply uncertainty.

Together, these figures tell the story of a transformation. What began as a cycle of excess inventory, unreliable forecasts, and unpredictable supplier performance was reframed through simulation and optimization. By modeling uncertainty, testing strategies against hundreds of possible futures, and back-testing results, C3 AI Inventory Optimization identified the right reorder parameters to lower carrying costs while maintaining service levels.

By running simulations across hundreds of demand and supply scenarios, the solution recalibrated reorder parameters to better reflect real conditions. The optimized policy reduced average inventory levels while maintaining service-level targets. As a result, the customer saw lower carrying costs, reduced risk of obsolescence, and greater resilience against supply variability — all without sacrificing customer satisfaction.

The case illustrates a broader lesson: volatility in demand and supply is inevitable, but inefficiency is not. With C3 AI, organizations can turn uncertainty into an advantage — anticipating disruptions, adapting policies dynamically, and building supply chains that are both lean and resilient.

Why It Matters

Global supply chains today are too complex and too volatile for static planning rules or guesswork. Businesses that cling to outdated practices risk bloated inventories, poor service, or both. C3 AI Inventory Optimization provides a scientific, data-driven way to establish inventory policies that are lean yet resilient. By automating what was once manual, simulating what was once theoretical, and validating what was once assumed, it transforms inventory management from a reactive chore into a proactive strategy.

The benefits are tangible: companies reduce holding costs, lower the risk of waste, maintain consistently high service levels, and increase supply chain agility. More importantly, they gain confidence that their inventories are right-sized not just for today but for the uncertainties of tomorrow. The result is resilience, efficiency, and service levels that meet the demands of both customers and the business.

Ready to Get Started?

Discover how C3 AI Inventory Optimization can transform your inventory management. Visit the site to learn more, request a demo, or speak with our team about how you can start right-sizing your inventory today.

About the Authors

Yimin Liu is a Lead Data Scientist at C3 AI and leads the data science development of C3 AI Inventory Optimization. He has extensive experience designing and deploying machine learning and optimization models in production — particularly for supply chain management — enabling optimization of large-scale inventories across global operations. Yimin has a PhD in Energy Resources Engineering from Stanford University.

Jianchen Yang is a Lead Data Scientist at C3 AI specializing in developing and deploying machine learning and optimization models for supply chain and inventory management. With a strong background in simulation and predictive modeling, he has contributed to multiple customer deployments of C3 AI Inventory Optimization, ensuring tailored solutions for diverse business needs. Jianchen received his PhD in Biomedical Engineering from the University of Texas at Austin.

Stefano Zavagli is a Senior Data Scientist at C3 AI, where he works on supply chain projects, developing optimization and forecasting solutions. Prior to C3 AI, Stefano worked on combustion engines R&D at Bosch, and Fiat Powertrain Technologies. He holds master’s degrees in mechanical engineering and operations research from UC Berkeley.

Minnie Tan is a Senior Data Scientist at C3 AI that has worked on multiple Inventory Optimization application customer deployment projects. Minnie work closely with project managers, engineers, and customers for fine-tuning C3 AI Inventory Optimization application for different use cases. Prior to joining C3 AI, Minnie interned in the financial services industry as an AI/ML associate and obtained a master’s degree in data science from New York University.

Justin Kendig is Principal Product Manager, Supply Chain at C3 AI and is responsible for product development of supply chain applications. Prior to joining C3 AI, his professional experience included supply chain and procurement in the manufacturing and retail industries. Justin earned a Bachelor of Science in Mechanical Engineering from Michigan Tech University, Master of Science in Mechanical Engineering from Bradley University, and a Master of Science in Predictive Analytics from Northwestern University.

Mehdi Maasoumy is a Vice President of Data Science at C3 AI, where he leads AI teams that develop machine learning, deep learning, and optimization algorithms to solve business problems including stochastic optimization of supply chains, reliability, sustainability, and energy management solutions across industries. Mehdi holds a PhD from the University of California at Berkeley in Optimization and Machine Learning. He has authored more than 50 peer-reviewed papers and books in machine learning and optimal control and is the recipient of three best paper awards from ACM and IEEE.