Enterprise AI helps navigate a shifting trade landscape with agility and speed

By Nikhil Krishnan, SVP and CTO, Data Science, C3 AI, and Lila Fridley, VP & GM, Asset Performance & Supply Chain, C3 AI

Tariff shifts can significantly upend the economics of established supply chains — driving cost spikes, disrupting manufacturing operations, pressuring profit margins, and altering price points across global markets, all while triggering cascading effects that compound complexity for enterprises. Supply chain leaders today are challenged with navigating this complex, volatile landscape — making difficult operational decisions on an ongoing basis while also re-directing capital investments to reduce future risk.

Adding to the macroeconomic pressures these businesses now face are internal challenges. Most organizations still operate with fragmented data spread across multiple ERP, planning, forecasting, manufacturing, and CRM systems — often with siloed teams and lacking true end-to-end visibility.

Without a unified view of the end-to-end supply network, companies can’t model tradeoffs, perform scenario analyses, and operate at the necessary speed and scale while collaborating with manufacturing and sales teams. Potential price increases can’t be fully and carefully modeled across teams in context of competitor moves or impact to demand. Even seemingly simple questions — like, “Where is my inventory and is it enough to meet next week’s demand?” or “Given current inventory levels, supply constraints, and supply pricing, what products should I prioritize making?” — can be difficult to answer.

In today’s environment, traditional planning cycles and execution strategies won’t keep up with the rapid and sweeping changes to business. Leaders need the ability to anticipate disruptions, model scenarios, and make fast, informed decisions across the entire supply chain network.

Tariffs: A Catalyst for Rethinking Supply Chain Strategy and Execution

Tariffs are forcing enterprises to fundamentally rethink core assumptions. Yet organizations without the tools to pivot quickly will reveal just how rigid their operations really are.

Instead of asking, “How do we reduce costs across procurement, production, and logistics?” leaders now face harder questions like, “How do we absorb or pass through rising costs caused by tariffs without losing margin or market share?”

These aren’t one-off disruptions. Tariffs are part of a broader pattern of global volatility — and companies that treat them as temporary anomalies will be caught off guard again — just as we saw in the height of COVID-19. In today’s world, constant change is the new normal. Resilience, not just efficiency, must be the priority.

What’s Needed: Unified Data, Anticipatory Planning, Real-time Execution

Adapting to this environment requires three tightly integrated capabilities. This starts with a unified data foundation: a real-time digital twin of the supply chain that connects supplier performance, logistics, production, and customer demand. This will give every function access to the same contextualized view displaying everything from port congestion to manufacturing capacity. This shared visibility is critical for cross-functional decisions — that are consistent, fast, and trustworthy — under pressure.

Once data is unified, organizations can enable next-generation planning — powered by continuously updated, predictive models. Unlike static plans, this approach simulates a range of future scenarios and evaluates tradeoffs in real time, helping leaders plan for uncertainty.

But even the best plan is only as good as a company’s ability to adapt when reality changes. That’s where next-generation execution comes in. As market conditions evolve — tariffs spike, demand surges, or shipments are delayed — organizations need to respond in near-real time. For example, if a global consumer goods company faced a sudden tariff hike on packaging materials sourced in China, C3 AI can enable their teams to quickly identify affected SKUs, reroute available inventory to key distribution centers, and shift production to alternate facilities with lower cost exposure — all within hours. With C3 AI, execution becomes dynamic, intelligent, and responsive — capable of flexing day by day or hour by hour, as new challenges emerge.

Together, these three capabilities — a unified digital twin, scenario planning and modeling, and intelligent, adaptive, real-time execution — form the backbone of a modern, resilient supply chain.

Your AI Partner for a Scalable, Intelligent Supply Chain Transformation

Backed by over a decade of delivering Enterprise AI at scale, C3 AI combines deep supply chain expertise with a platform built for real-world complexity. That foundation powers the C3 AI Supply Chain Suite — a comprehensive set of applications uniquely suited to power the modern supply.

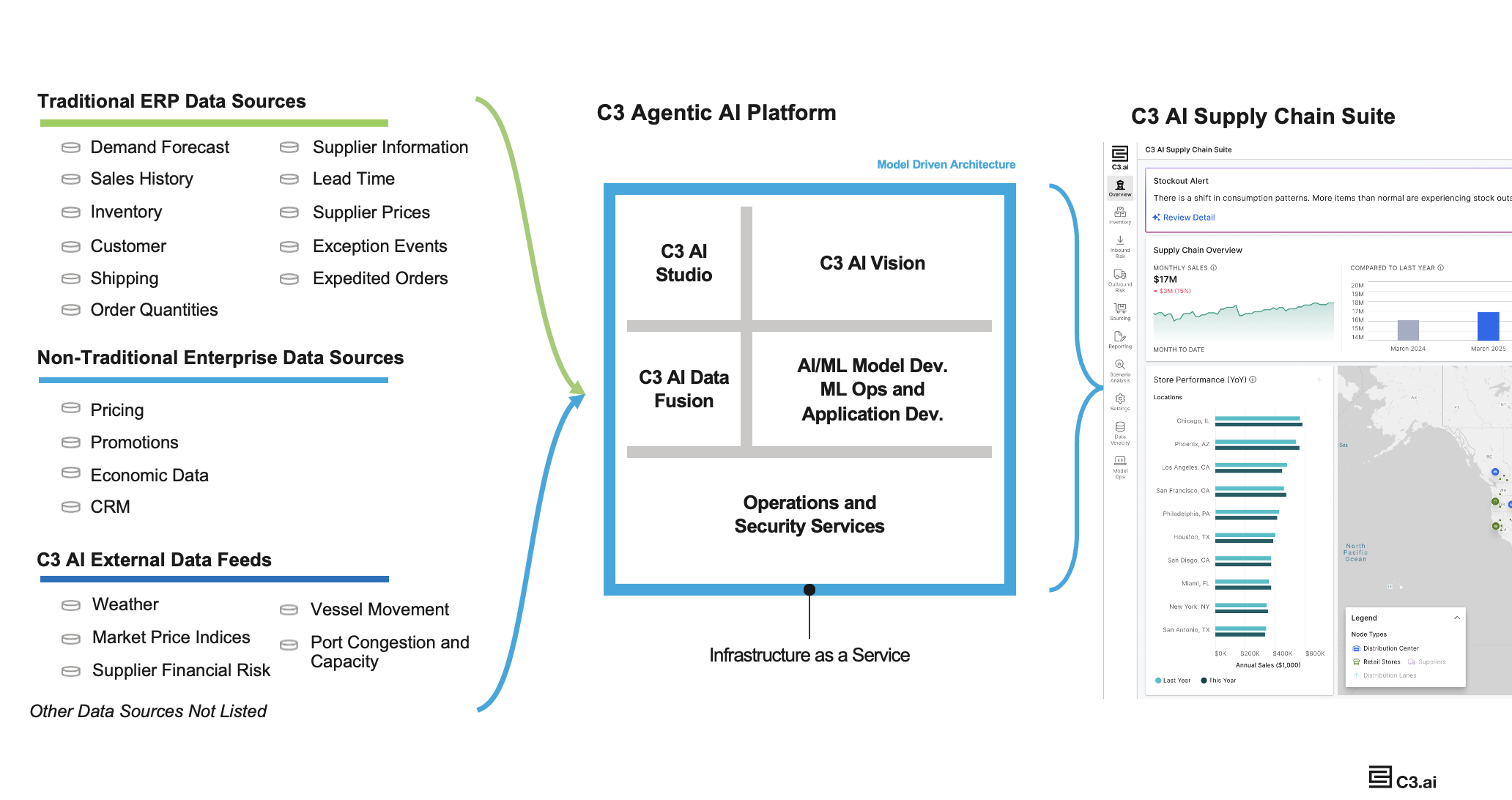

Using the C3 Agentic AI Platform, the C3 AI Supply Chain Suite unifies diverse data — from ERP systems to real-time external feeds —to form a shared, contextualized representation of the end-to-end supply chain and deliver AI-driven forecasting, optimization, and risk management across the supply chain.

These advanced AI applications are proven to predict, optimize, and plan with accuracy that alternative solutions can’t match. At the core are four capabilities that set C3 AI apart:

- C3 AI unifies disparate data across the supply network to deliver a single source of truth for decision making. At the core is an out-of-the-box knowledge graph object model that represents a wide range of internal and external enterprise data — spanning suppliers, inventory, demand, CRM, manufacturing, sales, production, logistics, news feeds, market trends, port traffic, supplier ratings, and other macroeconomic indicators. This model is continuously updated in real time, ensuring that supply chain decisions are grounded in the most current information available. With advanced data fusion tooling and prebuilt connectors, C3 AI rapidly integrates and unifies data from across even the most complex IT environments — supporting any number of ERP instances, logistics systems, transformation platforms, or manufacturing execution systems. This unified data foundation allows for seamless collaboration across functions and lays the groundwork for advanced AI-driven planning and execution.

- C3 AI’s next generation planning capabilities enable organizations to model complex, probabilistic scenarios that account for uncertainty and shifting market dynamics. Rather than rely solely on historical trends, planners can simulate a range of potential futures — capturing different macroeconomic conditions, tariff structures, or supplier disruptions. The system recommends contingency actions, such as proactively diversifying suppliers or adjust baseline allocations of materials across geographies and vendors. It also automates the modeling of cascading costs across the network and layers in demand functions to reallocate volumes and inventory in ways that maximize margin while satisfying customer demand. As conditions evolve, C3 AI dynamically evaluates product mix, cost exposure, and capacity to maximize profitability. At the same time, the system pro-actively flags potential future bottlenecks — such as constrained suppliers, critical parts, or logistics choke points — and identifies no-regret resilience investments. These could include sourcing alternatives, capacity expansions, or vertical integration strategies that mitigate future shocks before they occur.

- On the execution front, C3 AI empowers operations teams with real-time monitoring and the ability to intelligently respond. The system continuously detects anomalies and signals of disruption, including delays, demand shifts, quality issues, before they escalate. When unexpected fluctuations arise, C3 AI automatically generates recommended courses of action. For example, it may advise pausing shipment of affected components, rerouting materials to different global factories, expediting alternatives, or adjust the production schedule to focus on higher-margin or available products. These recommendations are context-aware and data-driven, ensuring that decisions are made quickly and in alignment with enterprise priorities. By combining automation, AI, and real-time data, C3 AI enables supply chain teams to shift from reactive firefighting to proactive, coordinated execution at scale.

- C3 AI user workflows are turnkey and purpose-built with users in mind. C3 AI user workflows deliver guided experiences to drive rapid decisions based on data, with detailed evidence packages for explainable AI. Across the organization, users collaborate in a single environment to work together for strategic planning and operational decisions in one environment — enabling users to interact with their data however they are most comfortable: with geospatial maps, spreadsheet-like grids, visual nodal networks, or natural language chat.

- C3 Agentic AI automates and orchestrates across data, AI/ML, and optimization on top of all existing investments. Enabled by the architecture of C3 AI’s out of the box unified object model and AI/ML and optimization models, C3 AI has patented an agentic orchestration model to deliver AI agents that retrieve relevant data, trigger AI/ML and optimization models, and notifies users of risks and issues while also executing actions to rebalance the network automatically without user intervention.

It is with these core capabilities that C3 AI delivers unparalleled strategic planning and rapid execution across the supply chain enterprise.

Imagine a global manufacturer relies on a third-party logistics partner to manage a global supplier network in Southeast Asia. Overnight, a new tariff is imposed on goods moving through the region, significantly increasing costs and threatening the viability of that partner.

Without advanced tools, this disruption could take weeks to assess and respond to — risking stockouts in downstream markets, missed customer commitments, and unnecessary margin loss.

With C3 AI, the supply chain team can immediately simulate this scenario using dynamic scenario modeling. In minutes, planners can evaluate what happens if that the supply source is lost, which regions will face supplier delays, how inventory will be impacted, and whether alternative routes or partners can absorb the volume. The system automatically predicts cascading effects, from shipping delays to revenue impact, and recommends mitigation actions, such as rerouting through other hubs, reprioritizing orders, or changing production plans. With these capabilities, organizations can plan effectively for the future to create response plans and to define a more resilient network that minimizes disruptions.

As the situation unfolds, C3 AI’s real-time execution engine integrates bi-directionally with existing MRP and ERP systems to keep operations in sync. The platform continuously monitors live data — lead times, stockouts, demand patterns, and supplier risks — and uses AI to predict disruptions like shipment delays. Then it automatically triggers actions such as inventory reallocations or material reorders.

Importantly, the system learns over time. As tariff-driven volatility becomes the new normal, C3 AI helps supply chain teams capture these conditions into future scenario plans, strengthening long-term resilience and preparing the organization for the next wave of uncertainty.

Across this process, cross-functional teams — sourcing managers, production teams, warehouse leads, demand planners, order managers, sales operations, pricing teams, and executives — work together in one environment, using shared data, unified models, and clear insights to make aligned decisions faster.

Resilience Starts Here

Tariffs create both strategic and operational pressures, forcing companies to rethink sourcing, pricing, and fulfillment in real time. But most organizations struggle to respond fast enough because their data is fragmented and their systems aren’t built for end-to-end optimization.

With unified data, built-in AI and optimization, and seamless integration across ERP systems, C3 AI enables predictive planning to make operational decisions quickly. So when disruptions hit, you don’t just react — you adapt intelligently and decisively.

Ready to build a resilient, future-ready supply chain? Get started today and learn how C3 AI can help.

About the Authors

Dr. Nikhil Krishnan is Senior Vice President and Chief Technology Officer, Data Science at C3 AI and is responsible for Data Science and Generative AI. Prior to C3 AI, Dr. Krishnan was an Associate Principal at McKinsey & Company, where he was a leader in McKinsey’s Advanced Industrials and Energy Practices. Dr. Krishnan was formerly an Assistant Professor at Columbia University. He also worked as a research scientist at Applied Materials, Inc. Dr. Krishnan earned a bachelor’s degree from the Indian Institute of Technology, Madras, and MS and PhD degrees from the University of California at Berkeley in Mechanical Engineering.

Lila Fridley is Vice President and General Manager, Asset Performance and Supply Chain at C3 AI. In her role, she leads product development, product marketing and industry solutions for asset performance, sustainability and supply chain optimization applications. Prior to joining C3 AI, her professional experience included oil and gas and supply chain operations. She earned a Bachelor of Science in Chemical Engineering from MIT, Master of Science in Operations Research from MIT, and an MBA from the Sloan School of Business at MIT.