A Series on Multi-Hop Orchestration AI Agents: Part 4 of 4

Continue the series: Part 1, Part 2, Part 3

By Ivan Robles, Senior Data Scientist, C3 AI

Supply chains are the backbone of global business, yet they’re increasingly vulnerable to disruption. From inventory management to supplier coordination, effective supply chain optimization requires a fine balance between efficiency, adaptability, and strategic foresight. C3 AI’s multi-hop orchestration agents deliver precisely that.

The Challenge: Complexity in Supply Chain Management

Supply chain optimization involves navigating large, multifaceted datasets, including inventory levels, supplier metrics, demand forecasts, and logistics details. Traditional tools often fall short in handling these challenges:

- Fragmented Data: Enterprises struggle with siloed data and a lack of centralized perspectives.

- SME Knowledge Gaps: Expert-defined business rules, such as reorder thresholds and vendor preferences, are hard to operationalize.

- Dynamic Conditions: Supply chain decisions must adapt to changing demands and unpredictable disruptions.

C3 AI’s Solution: Multi-Hop Orchestration Agents

C3 AI’s supply chain management agent addresses these challenges with a multi-agent system powered by advanced AI techniques. These agents combine expert-driven logic, real-time data, and advanced modeling to transform supply chain operations.

Key Capabilities

- Integrating Expert-Defined Business Rules: Supply chain optimization often depends on nuanced business rules known only to SMEs, such as specific lead times, reorder thresholds, or vendor preferences. The system should be configurable to incorporate these rules, enabling optimizations that reflect the unique priorities of each organization.

- Adaptive Demand Forecasting Based on Expert Insight: Forecasting is not just data-driven but also influenced by SME knowledge of industry cycles, product seasonality, or market shifts. The agent should allow SMEs to input these insights to enhance forecasting accuracy, reducing the impact of unpredictable demand on inventory and production planning.

- Custom Inventory Buffering and Safety Stock Strategies: Based on criticality, lead times, and supplier reliability, SMEs often define tailored safety stock levels for each product category or region. The agent should allow for these nuanced buffer strategies, adjusting inventory dynamically in response to both data patterns and SME-defined business logic.

- Prioritized Supplier and Vendor Optimization: Certain vendors might be preferred due to longstanding relationships, pricing agreements, or reliability. By incorporating SME-specified preferences, the agent can help prioritize suppliers in a way that aligns with both cost-effectiveness and strategic partnerships, ensuring alignment with broader business goals.

- Risk-Weighted Transport and Routing Decisions: SMEs often consider specific risks—like regional disruptions or vendor reliability—when deciding transport routes. The system should be able to incorporate these SME insights into routing algorithms, balancing cost and delivery speed with known risk factors to optimize logistics performance.

- Product-Specific Compliance and Sustainability Tracking: Compliance needs vary significantly across product types, suppliers, and regions, and SMEs are often the best source for setting these requirements. The agent should allow for custom compliance tracking metrics and sustainability goals based on SME knowledge, helping companies meet these goals while adhering to unique product-specific standards.

How It Works: Multi-Agent Collaboration

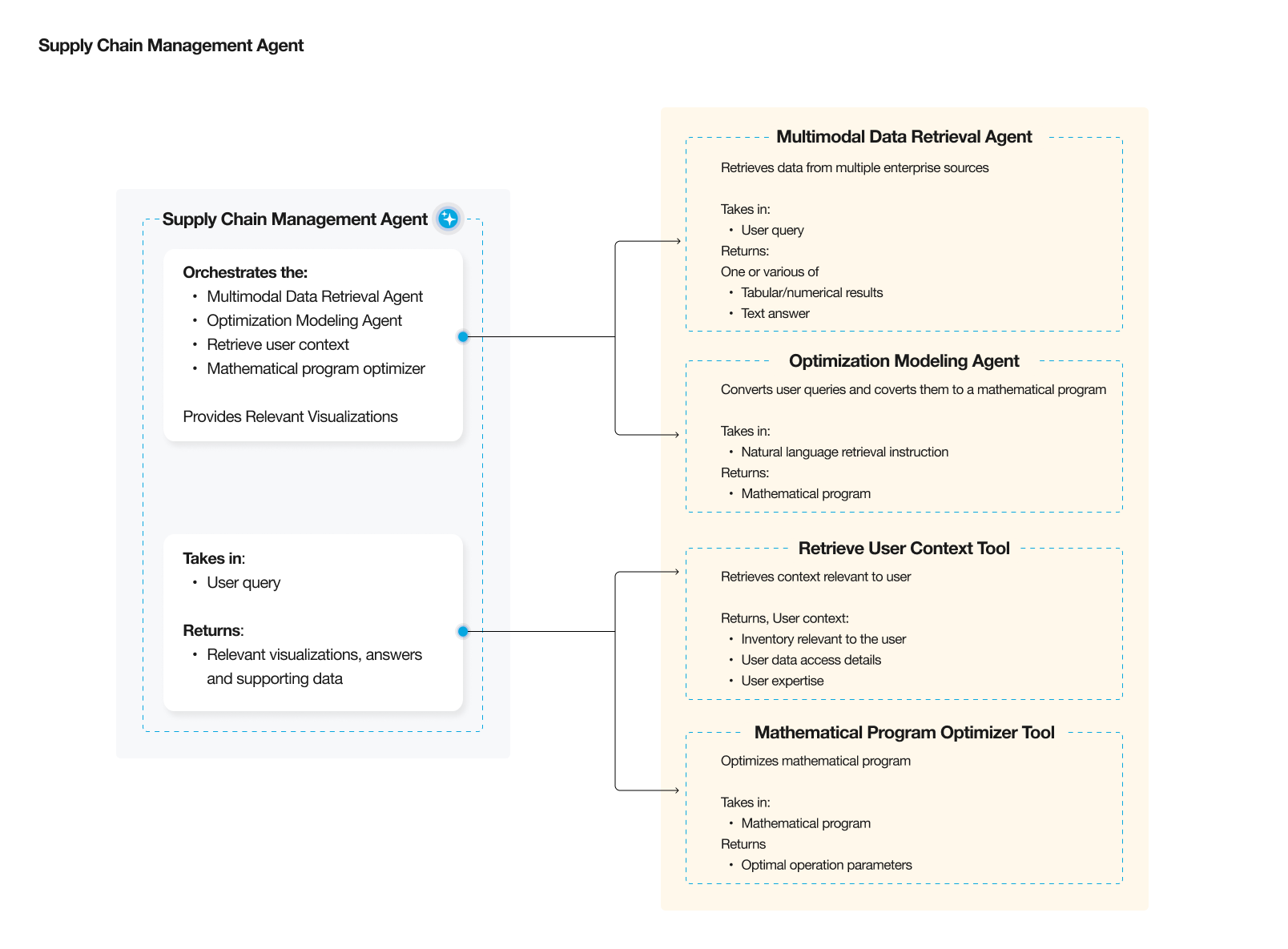

Conversational Code-Based Orchestration Agent

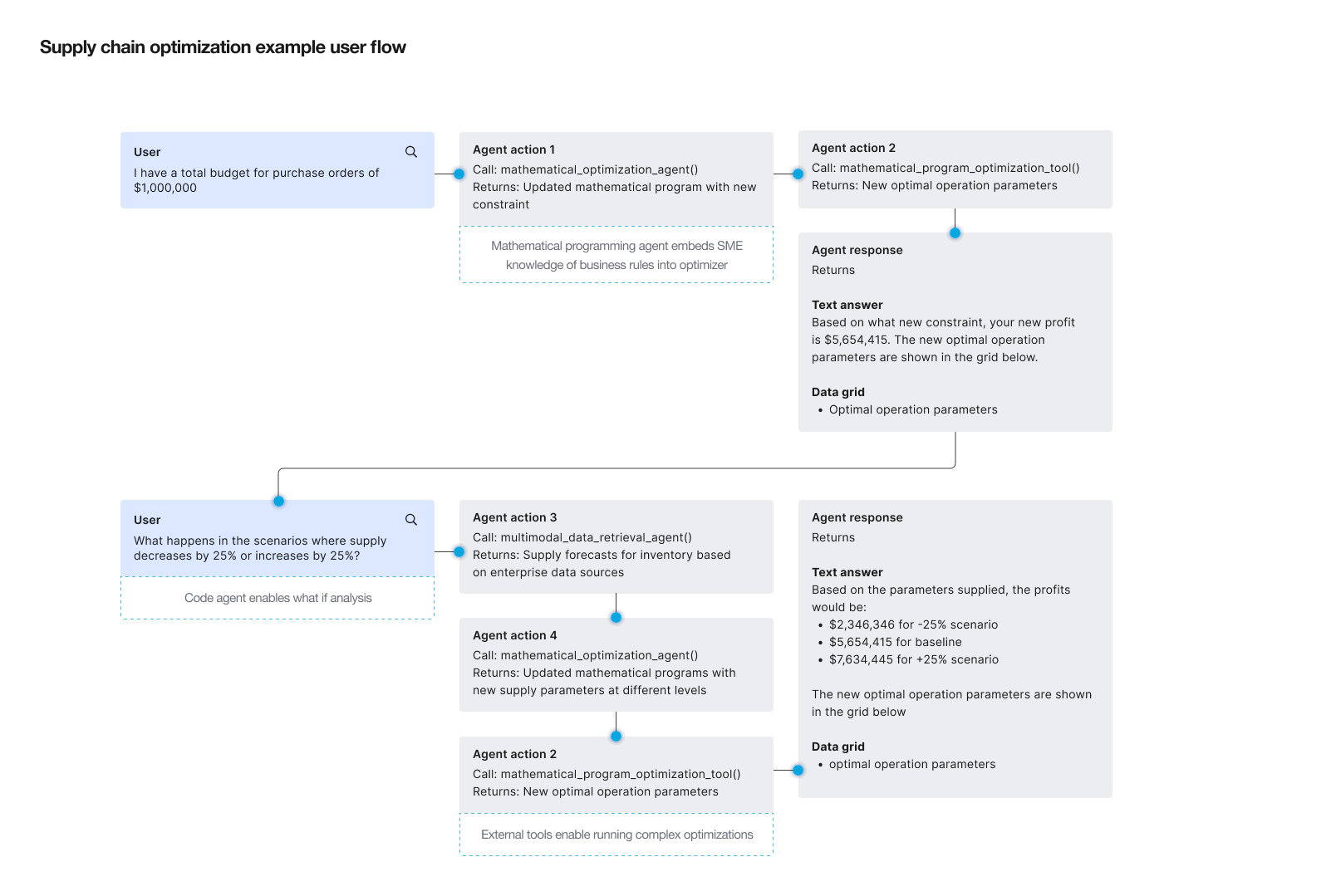

This agent acts as the main controller, converting user requests into instructions for other agents, coordinating the interaction of data retrieval, optimization, and analysis. By guiding users through complex queries and data manipulations, it ensures seamless interaction across the multi-agent system.

- Embedding Business Logic into Models: Incorporates specific SME-defined rules and priorities directly into optimization models, ensuring outputs align with unique business goals.

- Retrieving Data: Orchestrates data collection from multiple sources through the Multimodal Data Retrieval Agent, feeding the model with essential, up-to-date supply chain metrics.

- Visualizing Results for Enhanced Decision Making: Provides intuitive visualizations of optimization results, helping users make informed decisions by clearly displaying insights and trends.

- Carrying Out “What-If” Analyses: Allows users to test hypothetical scenarios, evaluating the impact of changes in demand, supply, or logistics constraints to support proactive planning and risk management.

Specialized Agents

- Multimodal Data Retrieval Agent: This agent interprets user requests to gather relevant supply chain data from various enterprise data sources for direct input into the optimization model (e.g., structured databases, text documents). DB, text docs, etc.). Using semantic matching, it connects loosely defined requests with the exact data needed to populate the model’s variables, including key metrics like inventory levels, supplier lead times, demand forecasts, and transportation costs. For instance, if a user requests “data on fast-moving items,” the agent retrieves essential fields like stock levels, reorder points, and lead times from different databases, consolidating them for efficient input into the mathematical optimization process.

- Optimization Modeling Agent: This agent builds custom optimization models for supply chain operations, incorporating SME-defined business rules and priorities. It converts these rules into mathematical constraints, focusing on tasks like inventory optimization or route planning to deliver actionable recommendations that align with the organization’s goals.

Supporting Tools

- Retrieve User Context Tool: This tool captures and retains user-specific inputs across a session—like priority products, facilities, or filters—so that downstream agents can tailor their responses without re-prompting. It ensures continuity across interactions, enabling more relevant and streamlined responses during multi-turn conversations.

- Context Retrieval Tool: This tool actively surfaces relevant enterprise knowledge—such as product catalogs, supplier profiles, or facility data—based on user queries. It helps personalize results by dynamically pulling the most pertinent information from internal systems based on real-time context.

- Mathematical Program Optimizer: This tool executes the calculations from the Optimization Modeling Agent, using algorithms to solve for the best outcomes, such as minimizing costs or improving efficiency based on real-time data.

The Advantages of C3 AI’s Multi-Hop Orchestration Agents

- Synergistic Step-by-Step Refinement with User Interaction: Multi-hop agents enable an interactive, iterative process where user input guides decision refinement at each step. By coordinating through C3 AI, agents align processing steps with user preferences and input, delivering an adaptable, accurate solution that evolves with user needs.

- Platform-Integrated Tool Coordination: These agents excel at leveraging C3 AI’s integrated tools—including databases, machine learning models, and specialized algorithms—while seamlessly orchestration across them. Agents can synchronize data exchanges, analyze data from multiple sources, and apply complex techniques, all within the C3 AI environment.

- Versatility Across Applications: Multi-hop agents can apply their coordinated approach across a broad range of applications, from multi-source data integration and automated workflows to real-time analytics and supply chain management. C3 AI’s collaborative infrastructure enables agents to operate across various domains, maximizing the platform’s potential for diverse industry use cases.

- Scalability in Platform-Orchestrated Functionality: The C3 AI platform amplifies scalability, allowing agents to coordinate access to specialized functionalities, APIs, and data sources at scale. As task complexity grows, agents can autonomously call additional platform resources, dynamically scale processes, and maintain efficient resource allocation across C3 AI’s infrastructure, such as running tools in a DAG and leveraging distributed processing.

Building Resilient Supply Chains

For a multinational retailer, implementing C3 AI’s supply chain management agent resulted in:

- 20% Reduction in Stockouts: Improved inventory visibility and proactive demand forecasting.

- 15% Decrease in Transportation Costs: Optimized routing and vendor prioritization.

- Sustainability Improvements: Customized compliance metrics ensured alignment with environmental goals.

C3 AI’s multi-hop orchestration agents provide a transformative framework for supply chain optimization. By blending advanced AI capabilities with expert knowledge, these systems offer businesses the tools they need to navigate complexity, drive efficiency, and achieve strategic objectives.

Learn how C3 Generative AI enables 90% time savings while delivering 90%+ accuracy for enterprise challenges.

About the Author

Ivan Robles is a Lead Data Scientist on the Data Science team at C3 AI, where he develops machine learning and optimization solutions across a variety of industries. He has a record of AI Kaggle competitions, where he ranked on the top 1.5% globally. He received his Master of Science in Advanced Chemical Engineering with Process Systems Engineering from Imperial College London.