Building Resilient Food Supply Chains with AI

Cargill is driving supply chain resiliency and efficiency using enterprise AI in demand planning, production scheduling, and other critical applications.

Download Case StudyIntroduction

Cargill’s stated purpose of nourishing the world in a safe, responsible, and sustainable way is taken very seriously by its owners, executives, and over 160,000 employees. As a trusted partner for food, agriculture, financial, and industrial customers in more than 125 countries, Cargill defines its business as transforming raw materials into finished goods, transporting products around the world, and providing insights to its farmer, customer, and internal stakeholders.

Cargill operates many complex supply chains. The efficient operation of these supply chains is critical not just to Cargill’s bottom-line but also to its farmers, industrial customers, and the societies it helps feed. Accurate demand and production planning is highly critical as raw materials and finished food products have limited shelf life. Manufacturers are constantly challenged by short lead times, last minute order changes, and strict regulatory requirements (e.g., ensuring workers have sufficient time to clean production line equipment). Potential inaccuracies in demand forecasts and suboptimal production schedules can lead to unfulfilled customer orders or excess production and waste.

Collaboration

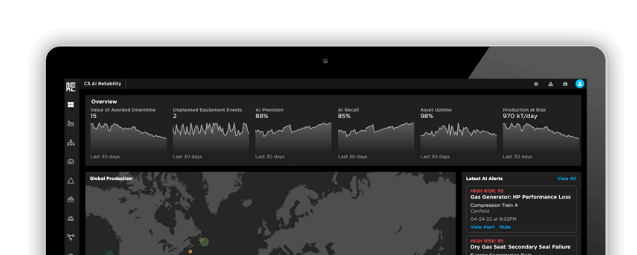

Cargill aspires to build resilient, sustainable supply chains that create unmatched customer value by creating end-to-end visibility, modernizing its capabilities, unlocking the value of data, and transforming to an anticipatory supply chain. It is in pursuit of this vision that Cargill started working with C3 AI in 2020 to build one core platform that is rapidly modernizing its multiple supply chains at scale.

Cargill has configured and implemented multiple AI supply chain applications to address critical challenges:

- C3 AI Production Schedule Optimization creates optimal manufacturing schedules thereby improving fill rates, reducing transition times, and improving operational efficiency while reducing production costs.

- C3 AI Demand Forecasting is generating daily demand plans and has significantly improved forecast accuracy by leveraging an entirely new set of data sources.

- Cargill leveraged the C3 AI Platform to create a new application for freight intelligence that helps growers access freight price forecasts, maximizing their income and fostering greater collaboration.

With C3 AI applications addressing important use cases, Cargill has created strong momentum to build an anticipatory and resilient supply chain that generates unmatched customer value. Here are further details of Cargill’s journey to creating intelligent supply chains.

“C3 AI is helping us build anticipatory supply chains that are critical to supply chain resiliency, sustainability, and unmatched customer value”

Mark Ratcliffe

Vice President, Global Supply Chain Planning, Cargill

Solutions

01Transforming Production with Production Schedule Optimization

A typical food processing plant at Cargill produces millions of pounds of essential food every month across dozens of products and multiple production lines. Traditional production scheduling tools generate weekly demand forecasts that are not optimized for plant constraints and changes to daily sales orders, leading to out-of-synch production schedules, hours of manual intervention, and unfulfilled customer orders.

Cargill configured and implemented C3 AI Production Schedule Optimization on top of its existing ERP system to create optimal production schedules within known constraints to:

- Deliver a better customer experience with significantly improved On Time in Full (OTIF) deliveries.

- Improve production line utilization through reduced transitions.

- Reduce food waste in its manufacturing operations.

Improve employee engagement with time required to generate schedules After successfully piloting this solution in one plant, Cargill is in the process of rolling it out to multiple plants in North America and other regions.

02Freight Market Intelligence

Transportation costs are a significant factor for the entire food value chain and have seen substantial volatility since the outbreak of the pandemic. After rising sharply since May 2020 due to demand/supply imbalances and rise in fuel costs, transportation costs have fallen through most of 2022. These movements in transportation rates have significant impact on grower income as well as Cargill margins. Since prices are agreed between growers and Cargill at the time of planting, transportation costs must be estimated for the harvest time, many months later. Accurate transportation cost estimates are critical to ensuring farmer income and Cargill’s competitiveness in local markets.

Cargill has worked with the C3 AI platform to develop the Freight Market Intelligence application that ingests a diverse set of data from harvest volumes, weather, fuel prices, and transportation spot prices to road conditions, truck demand & supply, and macroeconomic factors. AI models use the data to create forecasts for freight prices, supported by evidence packages that explain the drivers of the forecast. The application also supports Cargill with scenario modeling, forecast performance analytics, and P&L impact analysis.

By implementing the Freight Market Intelligence application, Cargill is helping maximize growers’ income, manage Cargill freight exposure, and foster collaboration between customers and suppliers.

03Forecasting as a Service

Cargill demand planners in every business and region perform the critical task of demand forecasting, which drives the entire supply chain, manufacturing, and procurement activities. Due to siloed business practices, there can be substantial variation in the accuracy and performance of forecasts across the company. To bring best practices and increase forecast accuracy across the company, Cargill is leveraging the C3 AI Platform and the C3 AI Demand Forecasting application to create their Forecasting as a Service program.

The idea behind Forecasting as a Service is to provide completely centralized support for some areas of the Demand Planning process (such as Statistical Forecasting) and collaborate closely with Demand Planners in other areas such as data maintenance, demand sensing, and performance management where common best practices and centralized support can improve forecast performance. Areas which require deep knowledge of the business and/or region such as commercial intelligence and decision support are retained for the demand planners embedded in each business and region.

By creating Forecasting as a Service and supporting demand planners in relevant areas, Cargill is systematically improving:

- Accuracy: Improved forecast accuracy up to 5% compared to current statistical, ERP driven approach by leveraging Machine Learning and external data sources.

- Efficiency: with less time spent by Demand Planners in generating detailed forecasts and more time collaborating with the business.

- Trust: Insights on forecast drivers using Machine Learning interpretability features and evidence packages.

- Flexibility: Configured forecasts across diverse sets of products, customers, locations, and time.

C3 AI Production Schedule Optimization

C3 AI Production Schedule Optimization

The Future of Intelligent Supply Chains at Cargill

Cargill is committed to a vision of providing an integrated, connected supply chain for its customers. While strong progress has been made in laying the foundation of a common, scalable architecture that can service all its businesses and regions, Cargill has its eye on future capabilities for its intelligent supply chains:

- End-to-end visibility: into every stage of Cargill’s supply chains and its suppliers provides the basis of food traceability, an issue that has gained much significance and continues to grow in importance.

- Anticipatory Supply Chain: building further on successes in forecasting, add predictive capabilities in identifying supply networks risks.

- Digital Customer Experience: improving not just OTIF and overall resilience, but also improving the visibility and engagement opportunities available to customers.

- Optimize and Automate: furthering efficiency gains through early implementation of various AI-driven optimization applications in areas such as raw material usage, MRO parts, inventory, and logistics.

Get in Touch

Learn how C3 AI Supply Chain Suite can help your organization in a personalized demo.