Dynamic Optimization of Inventory Management

Challenge

A global manufacturer of aircraft engines, avionics, and other aviation products maintains 90 major product lines with variations that require tens of thousands of parts from hundreds of manufacturers spread across the globe.

The complexity of the supply chain, and the costs of maintaining inventory, is significant. For just two of the components of its aircraft engines, the company maintains $600 million in parts inventory, including $400 million in fast-moving inventory, from hundreds of suppliers. Optimizing inventory levels can mitigate supplier delays and improve gross margins and revenue.

Approach

As part of its push to optimize operations and invest in software, the company undertook a trial of C3 AI Inventory Optimization application. By applying artificial intelligence to build a real time view of inventory levels and supplier risks, the company reduced inventory levels while still maintaining or even improving service levels. After a 10-week trial, the company demonstrated significant savings in inventory holding costs and accurately predicted supplier delays.

Project Objectives

- Integrate data from six supply chain systems to create a unified federated data image

- Apply AI to dynamically optimize inventory levels to improve service levels and lower inventory levels (currently $600m)

- Create a production-ready application to detect supplier de-commit risk and streamline workflow and analytics for supply chain managers

About the Manufacturer

- Fortune 100 software-industrial company

- $16 billion worldwide aerospace sales

- 40,000 employees

- 100 manufacturing sites

- 6 supply chain systems

Project Highlights

- 10-week completion

- 2 product families with over 1500 variations

- 3.5 years of inventory/manufacturing data

- 18 data types with 1 million rows of raw data covering 143,000 production orders from 113 suppliers

Results

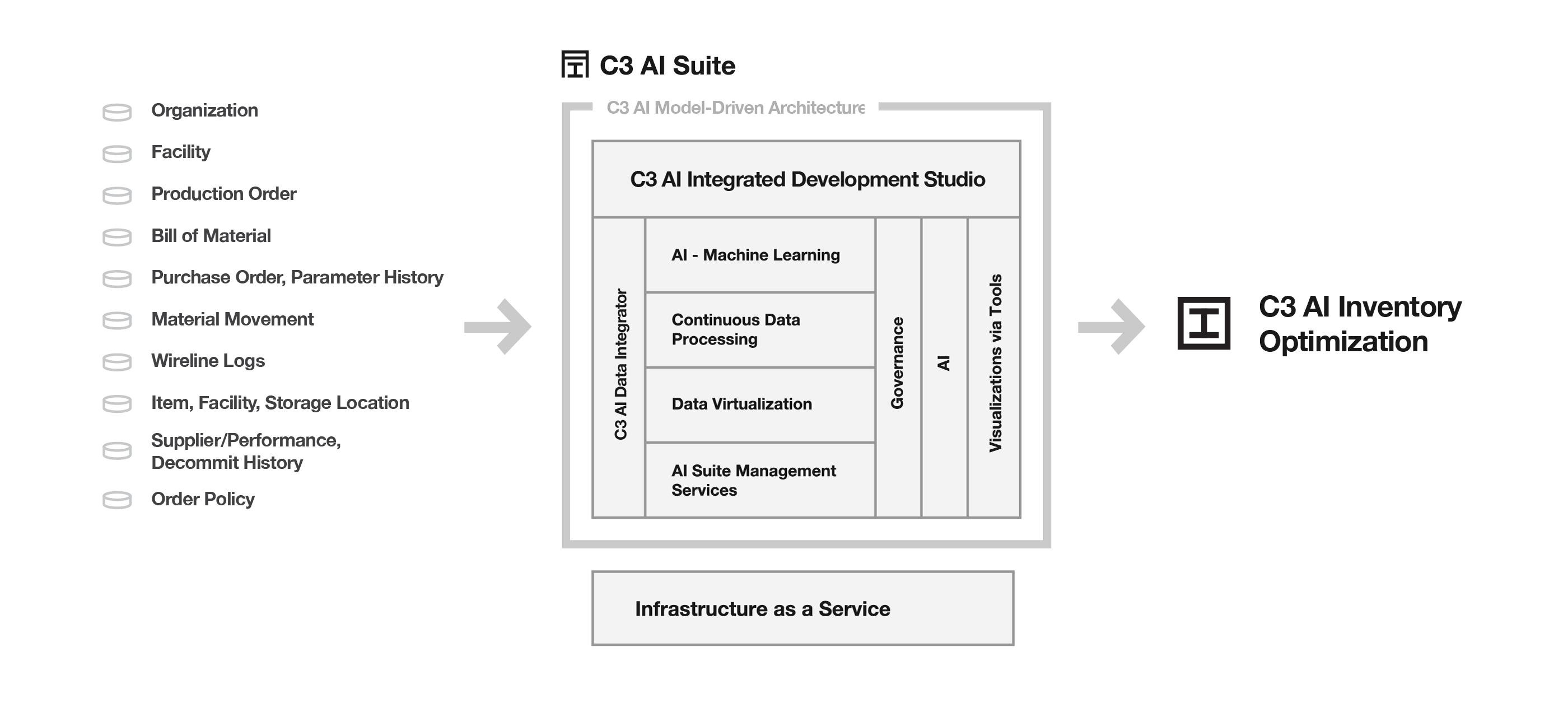

Solution Architecture