Enterprise AI for Demand Planning and Production Scheduling

Challenges

A global agribusiness and food manufacturer operates eight production lines and produces over 80 million pounds of food products per year across 90+ product codes and various raw materials. The plant’s only customer – a global retailer – exhibited highly variable demand that resulted in gaps with the manufacturer’s weekly demand forecast.

The company had attempted to address forecasting challenges using traditional demand forecasting solutions that relied on statistical algorithms that typically generated a demand forecast every week. However, given short shelf life of food products, sales orders were sent to the plant with little lead time, sometimes on a daily basis. When these sales orders deviated from the forecast, demand planners lacked the time to modify the active demand forecasts and the downstream production schedules leading to unfulfilled customer orders.

The company procured additional rule-based solutions to improve production scheduling, but ran into challenges when trying to optimize schedules and failed to significantly improve manufacturing operations. To address these challenges, the global food manufacturer decided to configure the C3 AI Demand Planning and C3 AI Production Schedule Optimization applications.

Approach

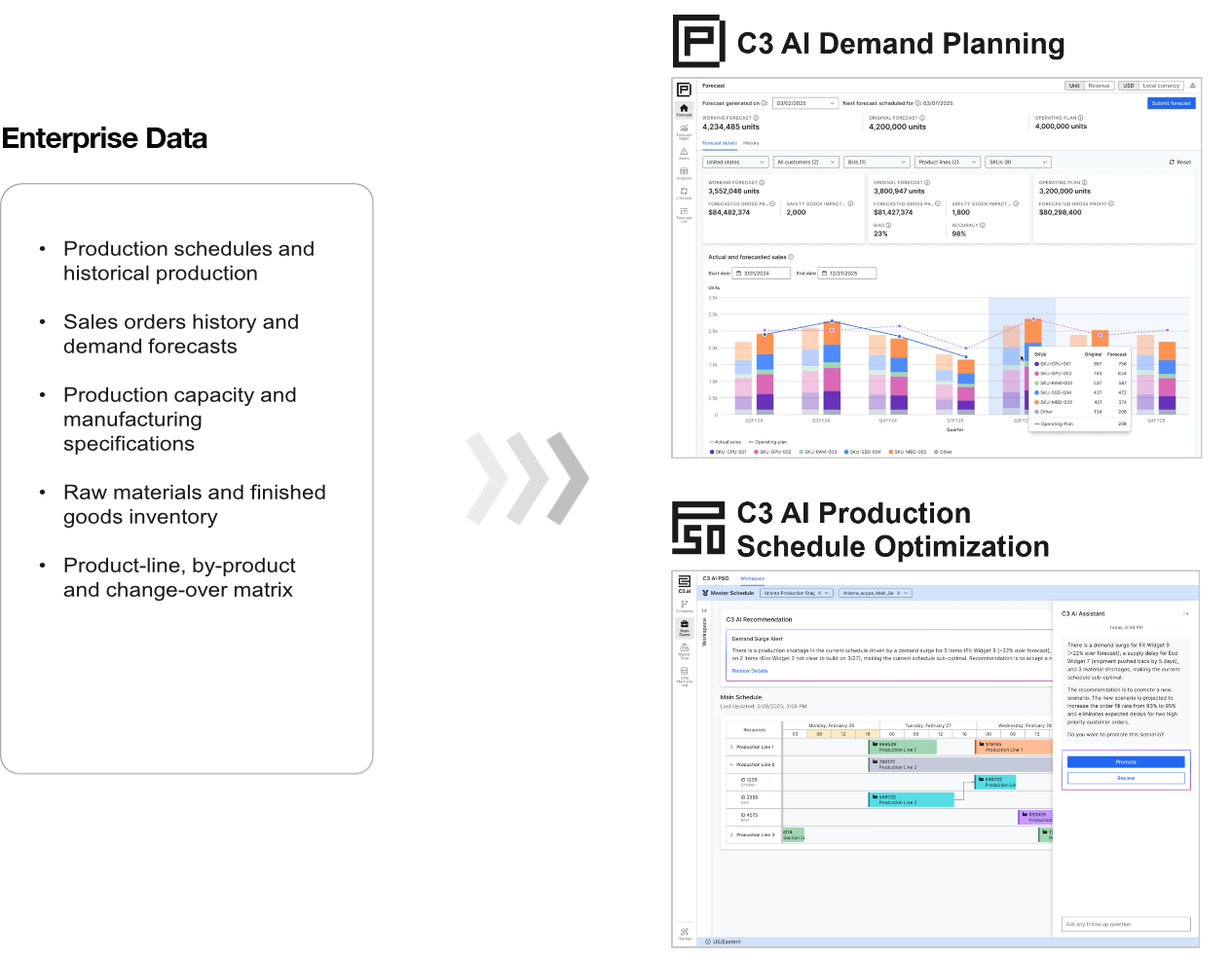

The C3 AI team began by ingesting, cleansing, and unifying 18 different data sources that included historical demand forecasts, order history data, production history, manufacturing specifications and historical inventory levels, comprising of 72 million rows of data. The unified federated data image enabled the company to train and configure the C3 AI Demand Planning and C3 AI Production Schedule Optimization algorithms and applications.

To generate optimal production schedules, the C3 AI team then configured C3 AI Production Schedule Optimization, which automatically generates schedules based on the latest available data and enables schedulers to reduce the time to generate schedules by 96%.

Finally, the C3 AI team configured the user interface across both C3 AI Demand Planning and C3 AI Production Schedule Optimization that enables users to view critical manufacturing KPIs (e.g., fill rate, schedule adherence, planned production volume), identify KPIs at risk, evaluate and approve AI-recommendations, and develop multiple scenarios by tuning inputs into the scheduling algorithm.

Project Objectives

- Integrate and unify data from 18 disparate data sources (e.g., weekly demand forecasts, manufacturing specifications, material master data, shipping documents, inventory levels)

- Apply machine learning algorithms to generate daily demand forecasts from the customer’s weekly demand forecast

- Apply optimization algorithm to generate production schedules by line and by shift

- Configure the C3 AI Demand Planning and C3 AI Production Scheduling Optimization user interfaces to expose AI insights

About the Company

- $100+ billion in annual revenue in 2020

- ~1400 manufacturing and distribution sites worldwide

- 150,000+ employees

- 120+ countries of operation

Project Highlights

- Unified 72M rows of data for 88 product codes with 44 raw materials in

8 production lines - Configured the proprietary C3 AI neural network to generate daily demand forecasts 21-days into the future with a 8% uplift in accuracy

- Configured scheduling optimizer to recommend a production plan by shift over a rolling 14-day schedule

- Exposed unified data and AI insights in 5 configurable user interfaces screens across C3 AI Demand Planning and C3 AI Production Schedule Optimization

- Demonstrated economic value in only 16 weeks with clear deployment roadmap to scale to over 30 manufacturing plants

Results

Solution Architecture

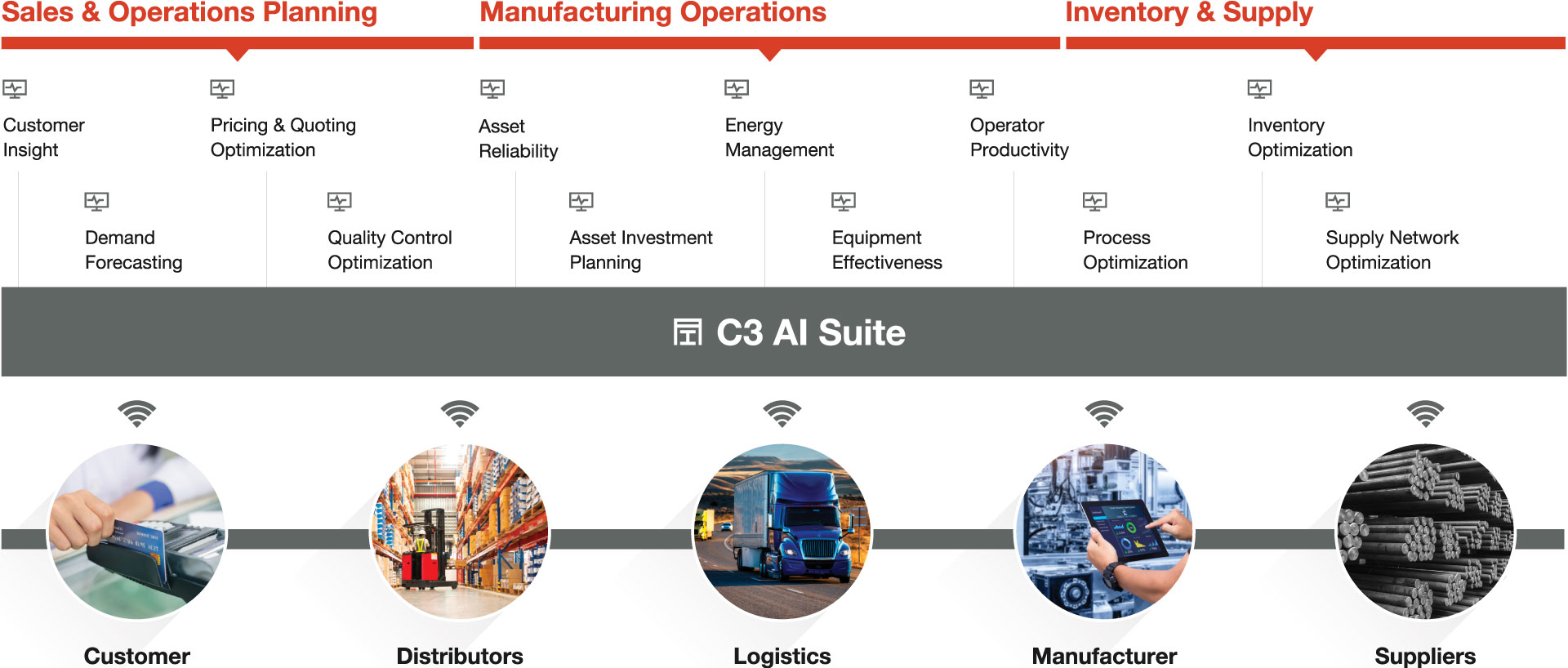

Enterprise AI for Manufacturing

The C3 AI Platform provides the necessary comprehensive capabilities to build enterprise-scale AI applications 18-26x faster than alternative approaches. The C3 AI Platform enables manufacturers to rapidly integrate petabyte-scale data from any/all enterprise systems, operational sources, sensor networks, and external providers to power machine learning models that generate predictive insights to solve previously unsolvable problems.

Many global manufacturers are already using the C3 AI Platform to drive digital transformation efforts, generating results such as: reducing inventory by as much as 35%, lowering waste caused by quality defects by over 20%, and generating hundreds of millions of dollars in economic value annually.