Improving Drug Manufacturing Reliability and Performance

Download the PDF to read the full story - Download

Challenge

A global pharmaceutical company produces, distributes, and markets 40 distinct drugs to over 120 million patients annually. The company’s top priority is to ensure patients receive uninterrupted supplies of therapy, which requires minimizing manufacturing production delays.

In the company’s largest biologics manufacturing plant, 100+ distinct systems must operate continuously and seamlessly throughout a two-month cycle to produce a single batch of drugs. An unanticipated system failure may compromise the drug quality and lead to scrapped batches or production delays. Lost revenue from unanticipated system failures can amount to $40,000 – $70,000 per hour at this single plant, or up to over $50 million per year depending on the severity of the delays.

Approach

Prior to engaging C3 AI, the company lacked an effective approach to anticipate and prevent system failures. The C3 AI® team implemented and configured the C3 AI Reliability application to predict system failures in the company’s largest biologics manufacturing plant with $3 billion annual revenues. With C3 AI Reliability, the company can monitor system health and performance across the plant, anticipate failures up to 10 days in advance, take preventative action, and increase throughput by decreasing production delays and scrapped batches.

About the Global Pharmaceutical Company

- $24 billion annual revenue in 2019

- 120 million patient lives impacted

- 30 manufacturing plants worldwide

- 70,000 employees

Project Objectives

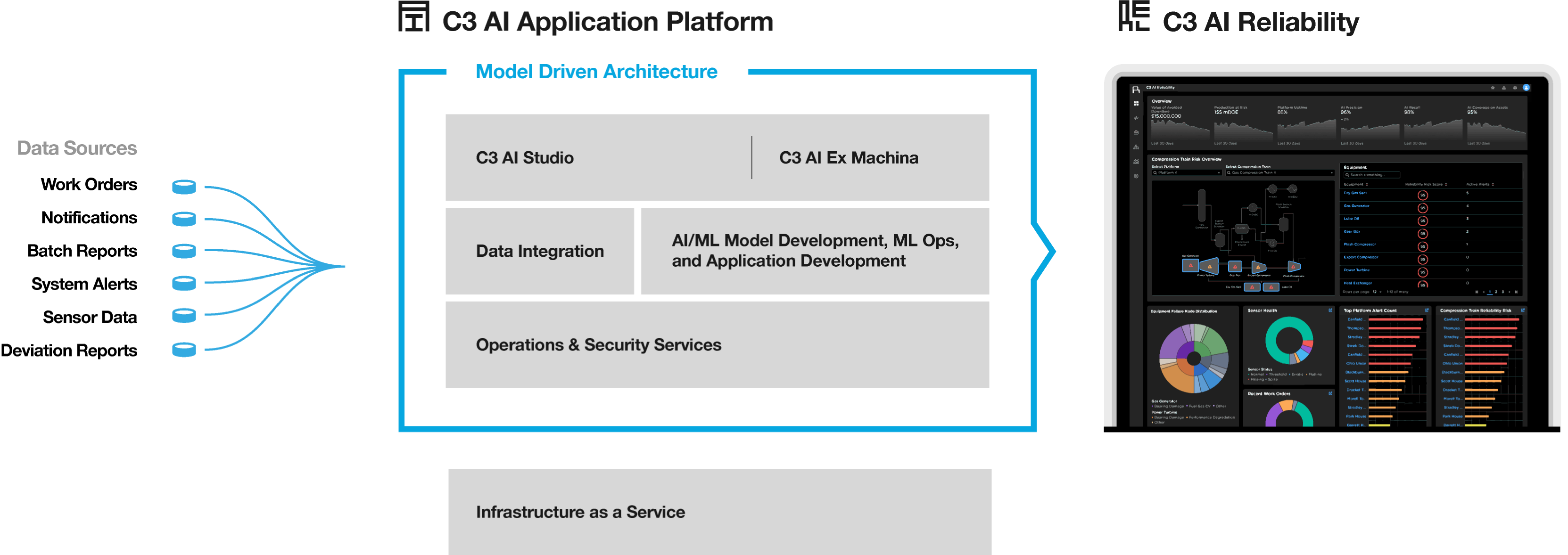

- Integrate and unify data from six disparate data sources (e.g., sensor data, sensor specs, workorders, batch records, plant alarms)

- Apply machine learning algorithms to predict or detect system failures and avoid production delays

- Configure the C3 AI Reliability user interface and expose AI insights and unified analytics to end users

Project Highlights

- 12 weeks from kickoff to pre-production application completion

- Integrated 5 years of historical data, comprising of 2 billion rows of data from 6 enterprise IT systems across 3 data networks

- Built an extensible data model with 27 C3 AI logical objects

- Developed 3,700+ timeseries analytics for machine learning models and application UI

- Configured and tested 800+ machine learning model permutations to predict system failures and detect anomalies

- Configured the C3 AI Reliability application user interface

Results

Solution Architecture

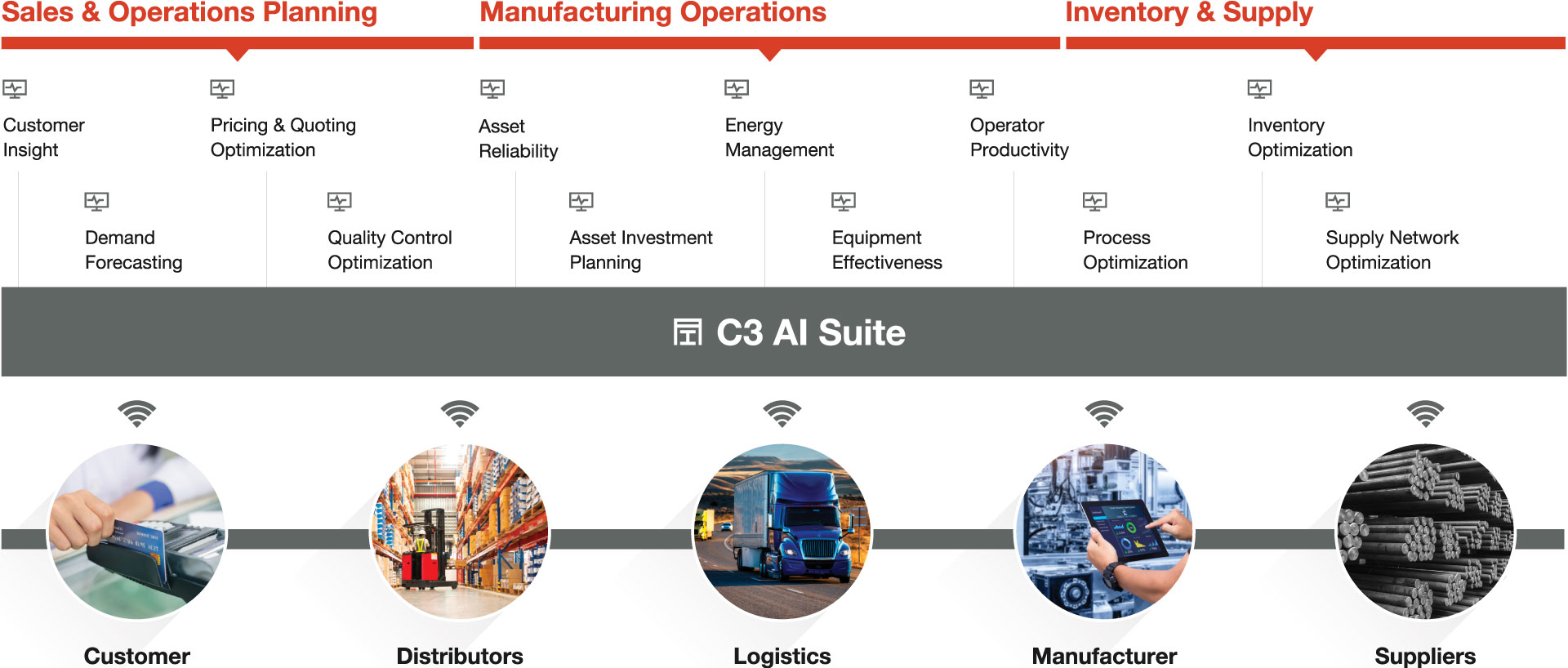

Enterprise AI for Manufacturing

The C3 AI Platform provides the necessary comprehensive capabilities to build enterprise-scale AI applications 18-26x faster than alternative approaches. The C3 AI Platform enables manufacturers to rapidly integrate petabyte-scale data from any/all enterprise systems, operational sources, sensor networks, and external providers to power machine learning models that generate predictive insights to solve previously unsolvable problems.

Many global manufacturers are already using the C3 AI Platform to drive digital transformation efforts, generating results such as: reducing inventory by as much as 35%, lowering waste caused by quality defects by over 20%, and generating hundreds of millions of dollars in economic value annually.