Global Beverage Company Reduces Unplanned Downtime with C3 AI Reliability

Download the PDF to read the full story - Download

Challenges

A multinational beverage company is one of the world’s largest producers of alcoholic beverages and soft drinks, with operations in more than 50 countries. A top priority for the company is to deliver high-quality products to customers with efficient manufacturing processes, including minimal unplanned downtime and maintenance costs.

Prior to engaging C3 AI, the company lacked a predictive maintenance solution to identify equipment reliability risks in its filling and packaging process. Maintenance was reactive, with frequent equipment failures requiring manual, time-intensive root cause investigation from experts and operators. Furthermore, new operators struggled to conduct investigations on their own and relied heavily on guidance from more experienced peers.

Approach

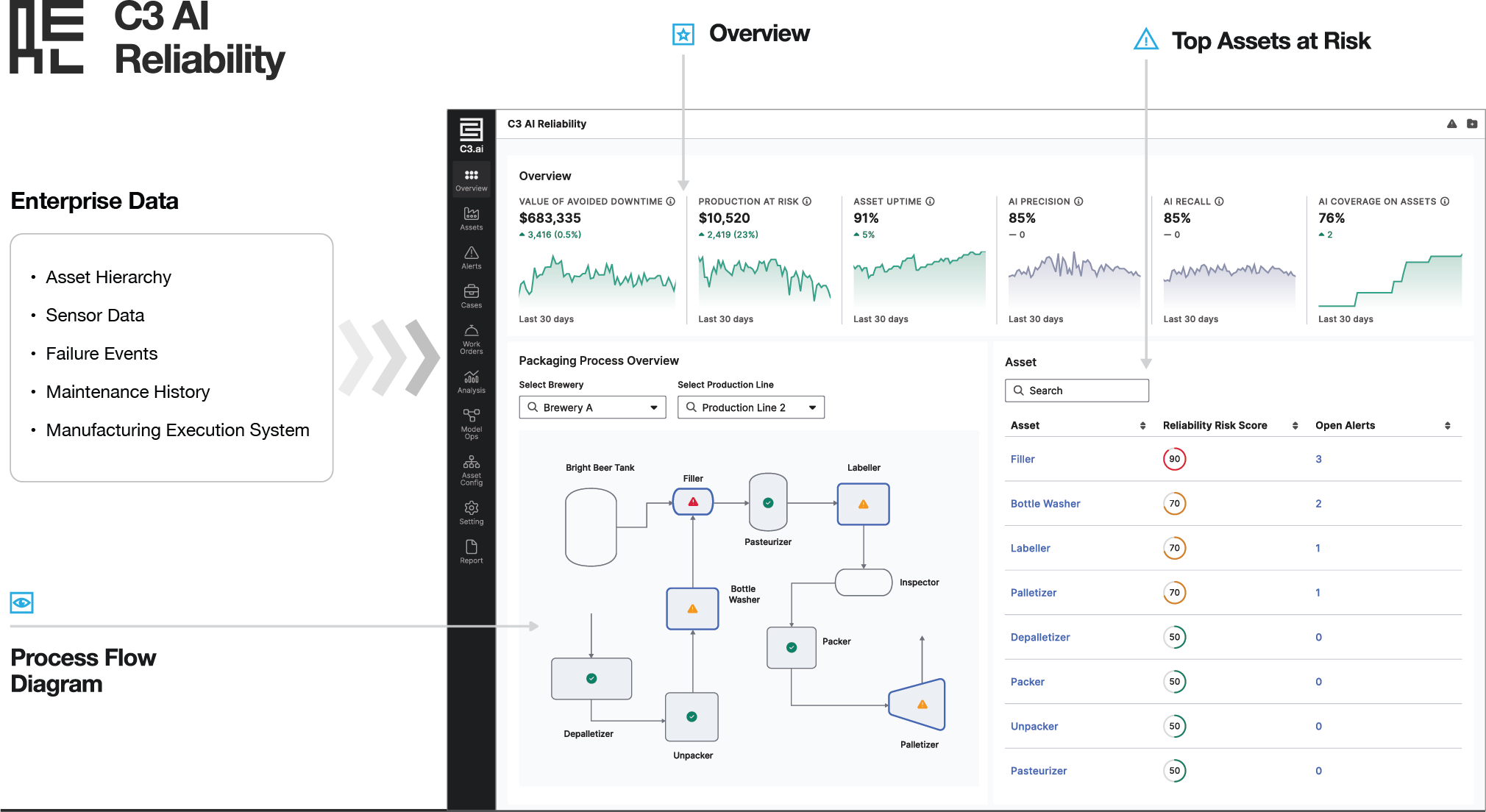

In 6 months, the company worked with C3 AI to configure and deploy C3 AI Reliability to predict unplanned downtime for 4 production lines at a brewery. The team ingested over 2 years of process and operational data including batch historian data, failure events, maintenance history, asset hierarchy, and production data to create a unified data image.

The joint team deployed 4 machine learning (ML) models on top of the unified data image to predict downtime for fillers up to 8 hours in advance. The team trained models with user feedback to rapidly reduce the number of predictive alerts for packaging experts from 25 to less than 5 per week during the initial production deployment. The ML models successfully predicted 100% of filler underfilling failure events in production.

Due to the success of the initial production deployment, the company has deployed the application into production and configured live data connections to raise alerts in near real-time. In the next phase of scale-out, the company is considering scaling C3 AI Reliability across additional equipment types at 27 breweries and 84 production lines globally.

About the Company

- $15+ billion in annual revenue

- 50+ countries of operation

- 100+ breweries globally

- 30,000+ employees

Project Objectives

- Predict and reduce unplanned downtime for fillers in the beverage packaging process

- Reduce operating costs by minimizing unexpected maintenance activities

- Provide prescriptive recommendations to operators with likely root causes and failure modes

- Configure the C3 AI Reliability application to visualize and interact with ML insights in a user-friendly interface.

Project Highlights

- 6 months from project kickoff to production-ready application

- Up to 8 hours of advance warning of potential equipment failure risks

- 2 years of historical data from 5 source systems integrated

- 4 machine learning models deployed to predict unplanned downtime events

- Configured C3 AI Reliability application user interface

Results

Solution Architecture