Global Cement Manufacturer Minimizes Equipment Downtime with Advanced AI

Download the PDF to read the full story - Download

Challenges

Cement manufacturing is a highly interconnected process that relies on the seamless operation of critical assets, most importantly the vertical roller mill. Unexpected failures of the vertical roller mill and other assets can halt the entire production line, leading to millions of dollars in revenue loss and significant maintenance costs.

Prior to engaging C3 AI, a global cement manufacturing company had attempted to develop its own in-house predictive maintenance application. However, the application was not well adopted by internal users like manufacturing experts and reliability engineers. The solution struggled with poor AI performance and to scale across all assets and all facilities globally. For the small number of assets being monitored, technicians in the company’s plants were flooded with false positive alerts and did not have time to investigate each alert properly.

The high alarm rate was due to the underlying ML approach, which relied on univariate sensor-based algorithms. This approach was overly sensitive to small variations in sensor data, resulting in hundreds of false alarms per month.

Approach

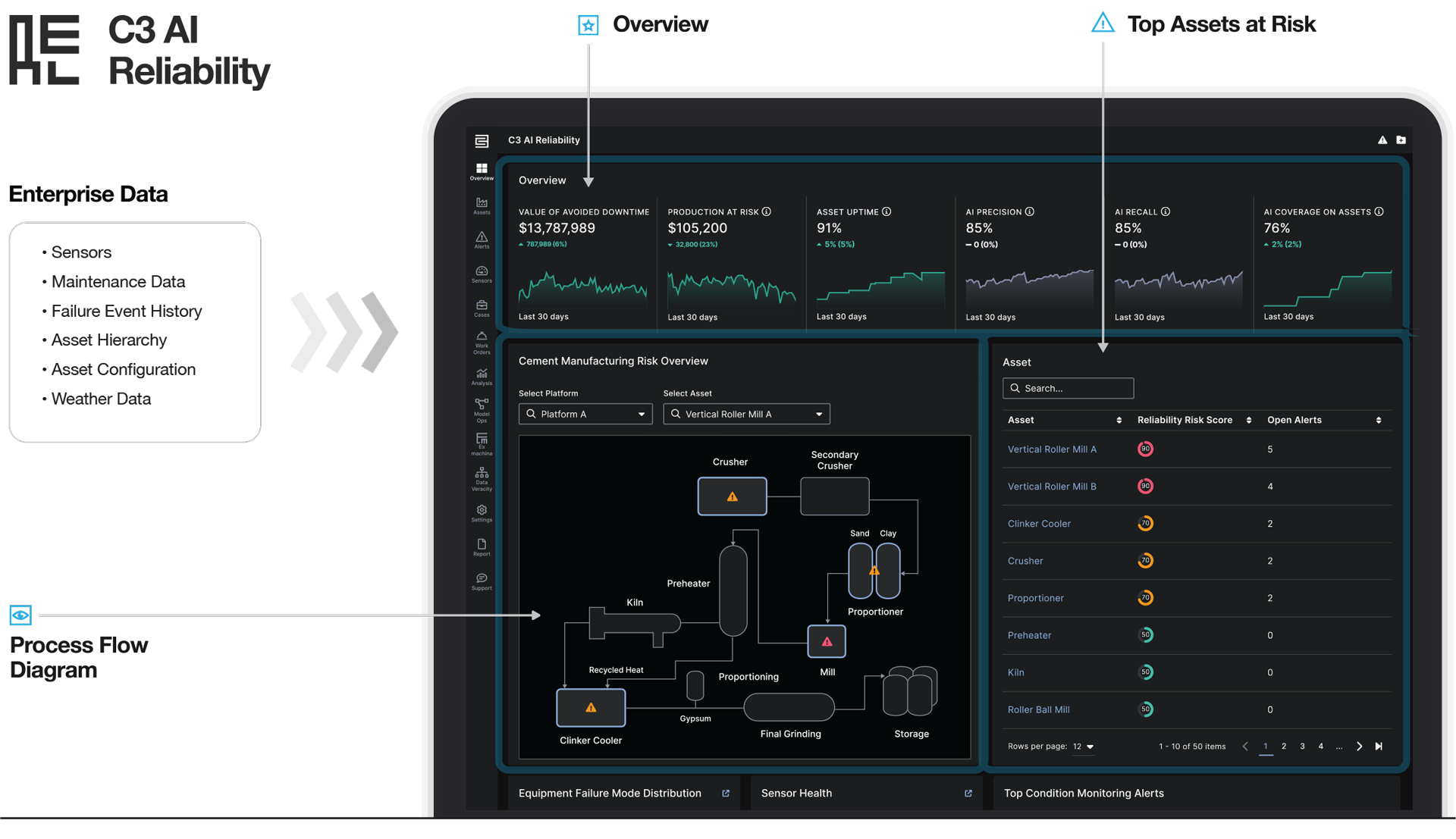

Over 26 weeks, C3 AI partnered with the cement company to configure and deploy C3 AI Reliability to monitor 10 vertical roller mills across 7 countries. The team started by ingesting, cleansing, and unifying three years of historical and live data. The data image, which combined sensor data, asset hierarchy, maintenance history, asset diagrams, and external weather feeds, enabled the company to deploy and operate C3 AI Reliability on up-to-date data.

The joint customer and C3 AI data science team applied a multivariate virtual sensor approach to detect anomalous events for vertical roller mills. Due to a lack of failure history, the team developed an automatic way to detect and mask faulty sensors, overcoming a previously manual and time-consuming task. Within 10 weeks, the team developed, validated, and deployed 50 machine learning models, one for each subsystem within the 10 vertical mills.

During the project, the team trained 11 customer data scientists and data engineers to deploy ML models to new assets. After training, customer data scientists were able to independently configure and deploy new models in less than 3 hours to continue to scale the application globally. Finally, the team configured the C3 AI Reliability user interface, developed two custom screens, and onboarded 50 end users across the 10 plants, driving widespread adoption of the new AI application.

About the Company

- $30+ billion annual revenue in 2022

- 70+ countries of operation

- 100+ manufacturing plants worldwide

- 70,000+ employees

Project Objectives

- Improve accuracy and precision of predicting equipment failures with early warning

- Integrate and unify data from disparate data sources to improve actionability of ML-generated insights

- Enable technicians to mitigate potential failures and avoid production delays

- Configure the C3 AI Reliability application to visualize and interact with ML insights in a user friendly interface

Project Highlights

- 26 weeks from project kickoff to production-ready application

- 50 ML models configured and deployed to predict asset failures and detect anomalies

- Deployed on the edge

- 3 years of historical data integrated, comprising 867 million rows of data

- 50 end users onboarded from 10 different plants

- 20 customer data scientists and data engineers trained to onboard assets and deploy ML models

- Configured the C3 AI Reliability application user interface, including 2 new customer-specific screens

Results

Solution Architecture

Benefits

With the C3 AI Reliability application, the global cement manufacturing company can now:

Generate

$10 million in annual economic benefit across all plants by minimizing unplanned downtime

Reduce

false positive alerts by 96% and improve the productivity of technicians

Predict

100% of failure events with at least 7 days advance warning for vertical roller mills

Drive

preventative action with detailed evidence packages

Guide

troubleshooting and maintenance activities to accelerate operations tasks

Scale

AI applications globally to every plant with a solution that can be locally deployed onsite

Configure

validate, and deploy new ML models in less than 3 hours to dramatically improve data science productivity