Reducing Inventory Costs and Optimizing Service Levels

Challenge

A large electronics manufacturer and distributor delivers over a hundred billion units across 140 countries each year.

The company’s global operations team has committed to reducing 20% of inventory by 2021 without impacting service levels. In order to achieve this objective, inventory managers must purchase the right parts at the right times in the right volumes, requiring an integrated, accurate view of the global supply chain.

Prior to engaging C3 AI, the company was struggling to unify its disparate demand and inventory systems and data sources, forcing inventory managers to reorder parts based on static thresholds driven by historical demand and anecdotal evidence.

Approach

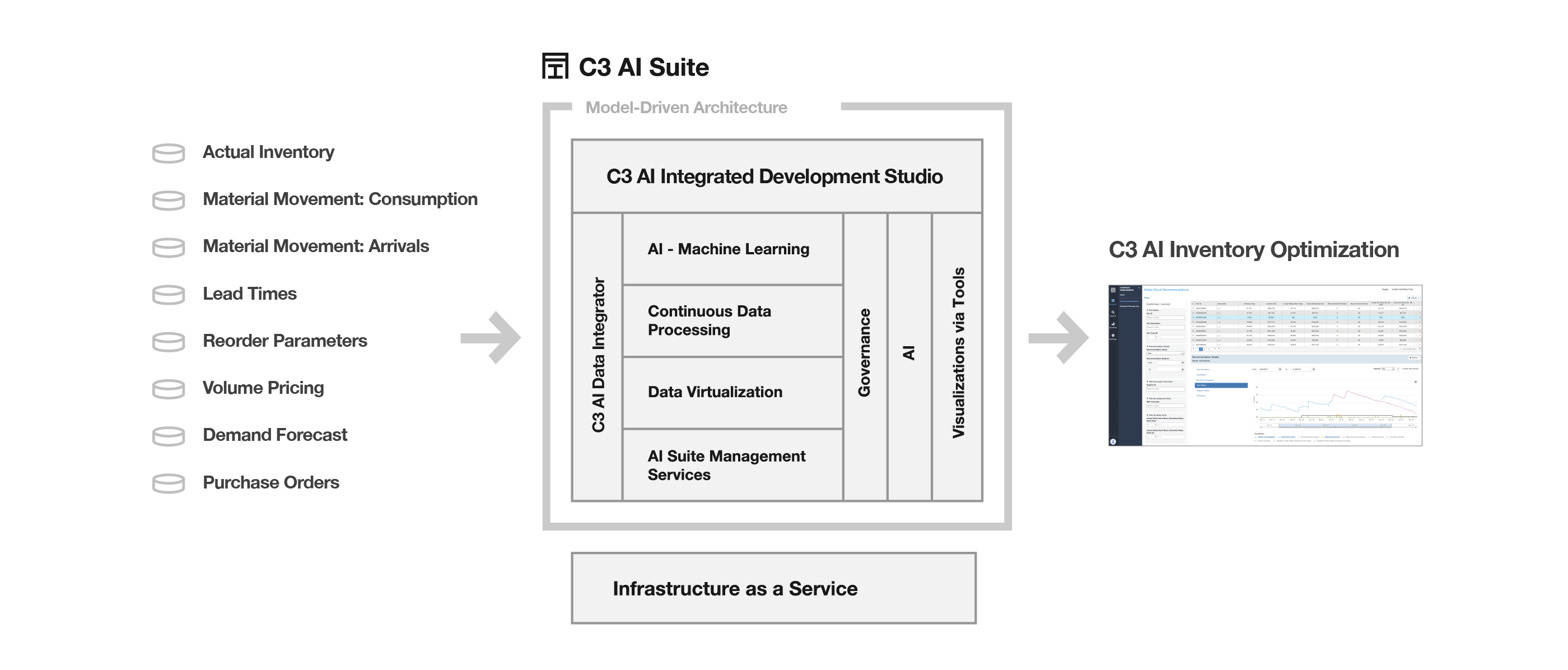

The company selected the C3 AI Inventory Optimization application to address this challenge and engaged C3 AI to begin a phased rollout across its global operations, beginning with the company’s largest distribution center, located in the United States. C3 AI Inventory Optimization enabled the distributor’s purchasing team to unify its siloed and disconnected systems, maintain optimal levels of safety stock, reduce inventory costs, and improve service levels.

About the Global Electronics Distribution Company

- $10+ billion annual revenue

- Over 100 billion units shipped per year

- Over 1 million customers across 140 countries

- 10,000+ employees

Project Highlights

- 6 months from kick-off to production-ready application for 10,000 in-scope SKUs

- 5 years and 16 million rows of historical inventory, demand, and supplier data unified

- User testing executed with 10 inventory managers to deliver an application UI that allows the company’s 100+ inventory managers to take action on inventory reduction recommendations

- Inventory managers accepted 74% of inventory reduction recommendations during product testing and review

Results

Solution Architecture

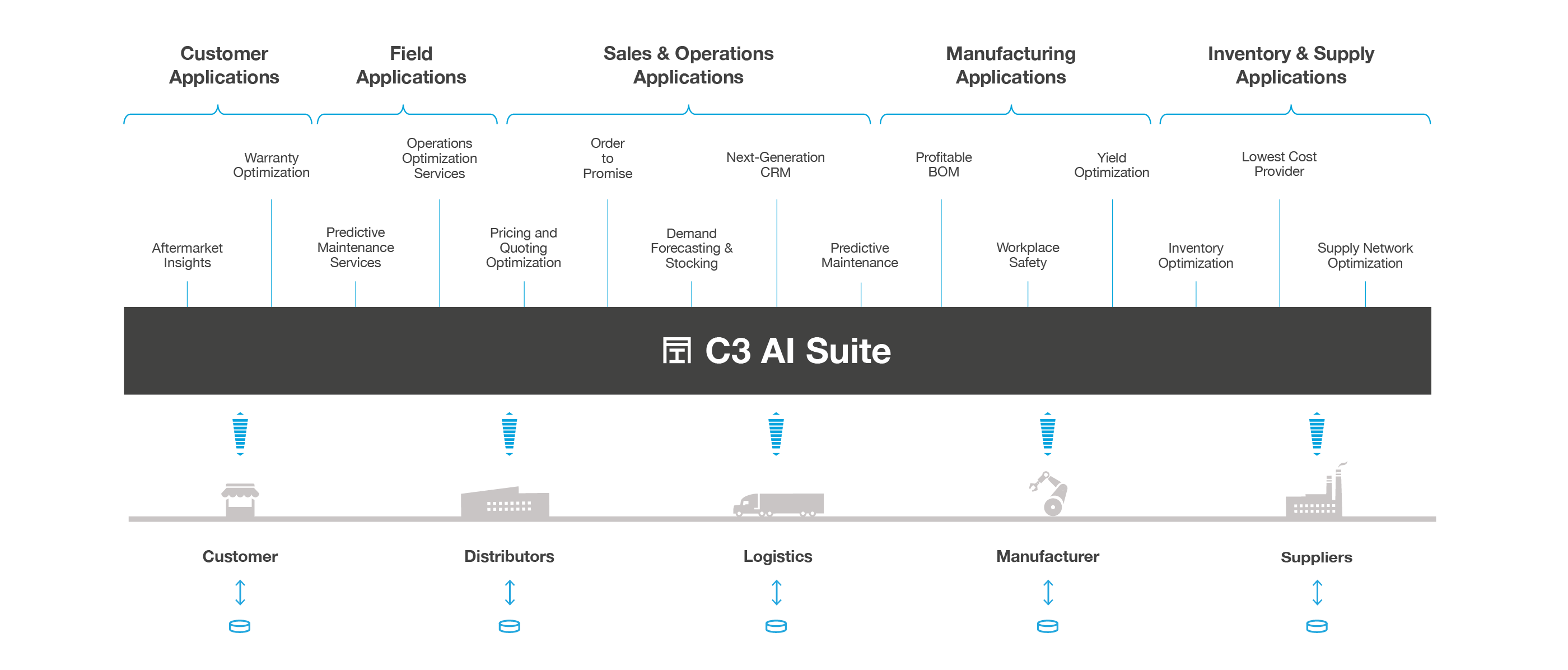

Enterprise AI for Manufacturing

The C3 AI Platform provides the necessary comprehensive capabilities to build enterprise-scale AI applications 25x faster than alternative approaches. The C3 AI Platform enables manufacturers to rapidly integrate petabyte-scale data from any/all enterprise systems, operational sources, sensor networks, and external providers to power machine learning models that generate predictive insights to solve previously unsolvable problems.

Many global manufacturers are already using the C3 AI Platform to drive digital transformation efforts, generating results such as: reducing inventory by as much as 35%, lowering waste due to quality defects by over 20%, and generating hundreds of millions of dollars in economic value annually.