- AI Software

- C3 AI Applications

- C3 AI Applications Overview

- C3 AI Anti-Money Laundering

- C3 AI Cash Management

- C3 AI Contested Logistics

- C3 AI CRM

- C3 AI Decision Advantage

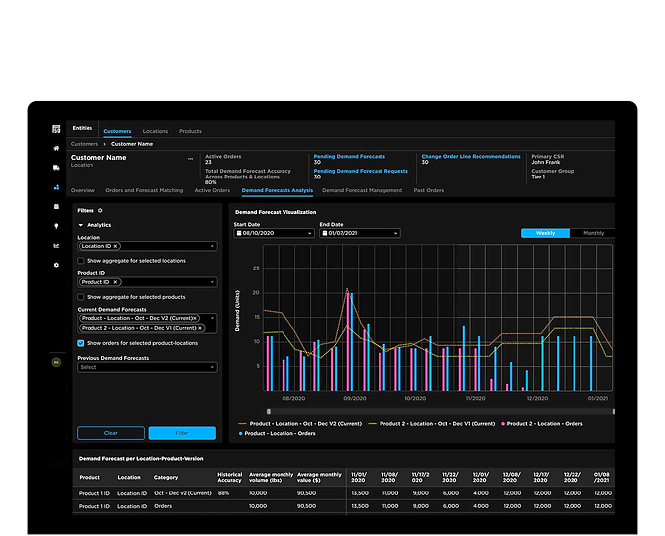

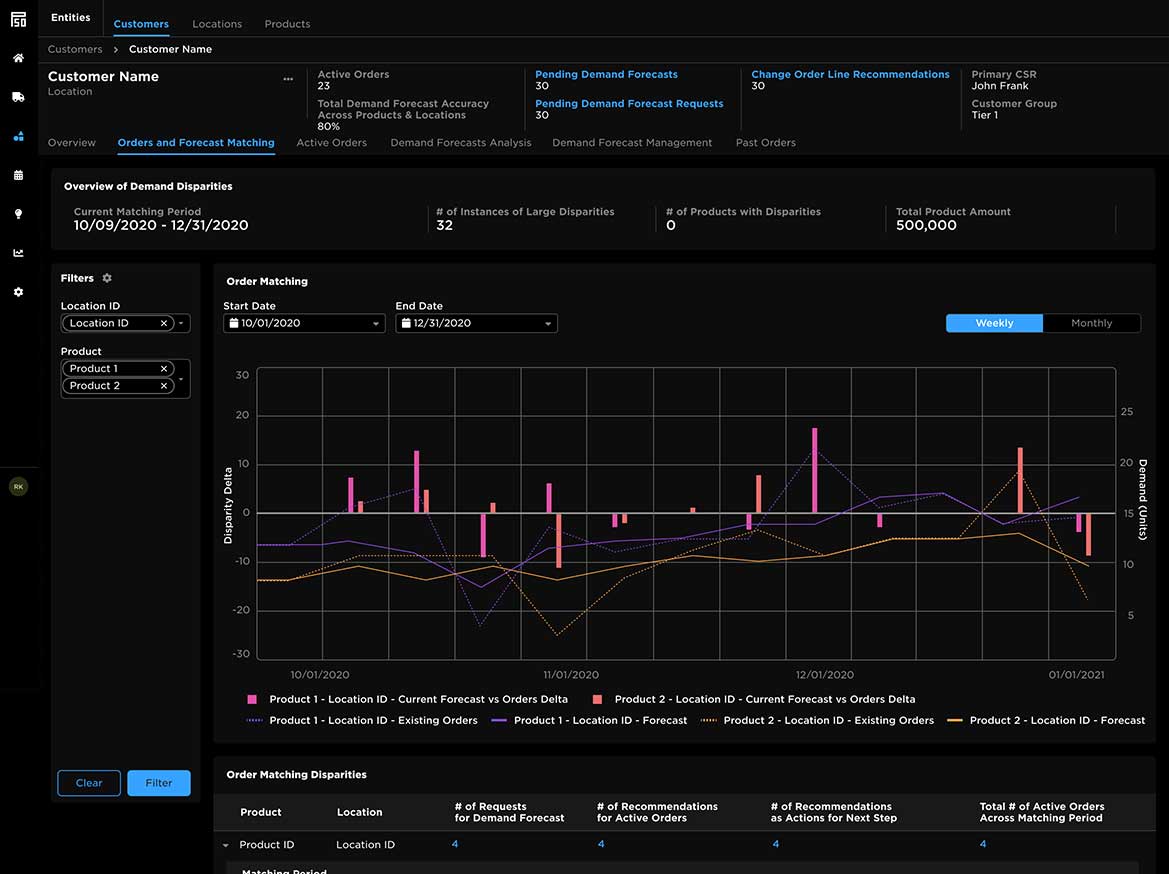

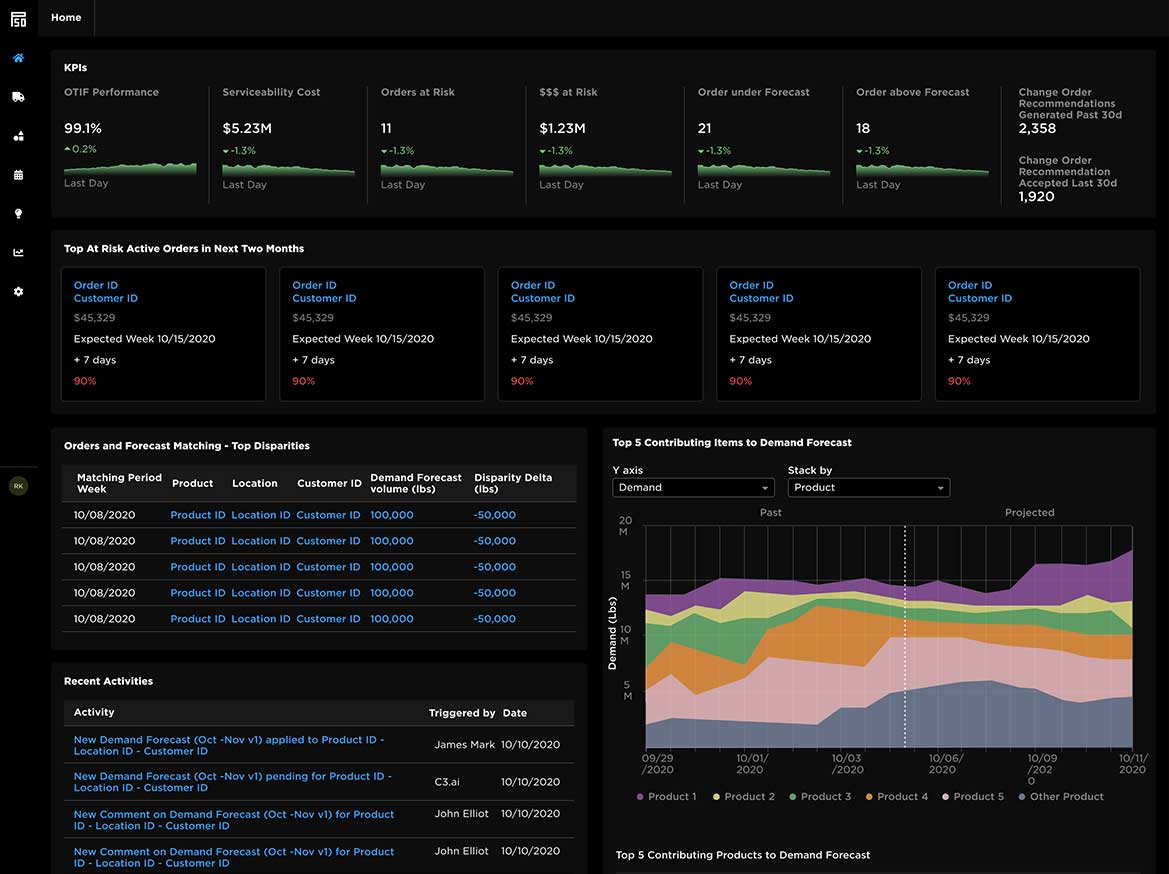

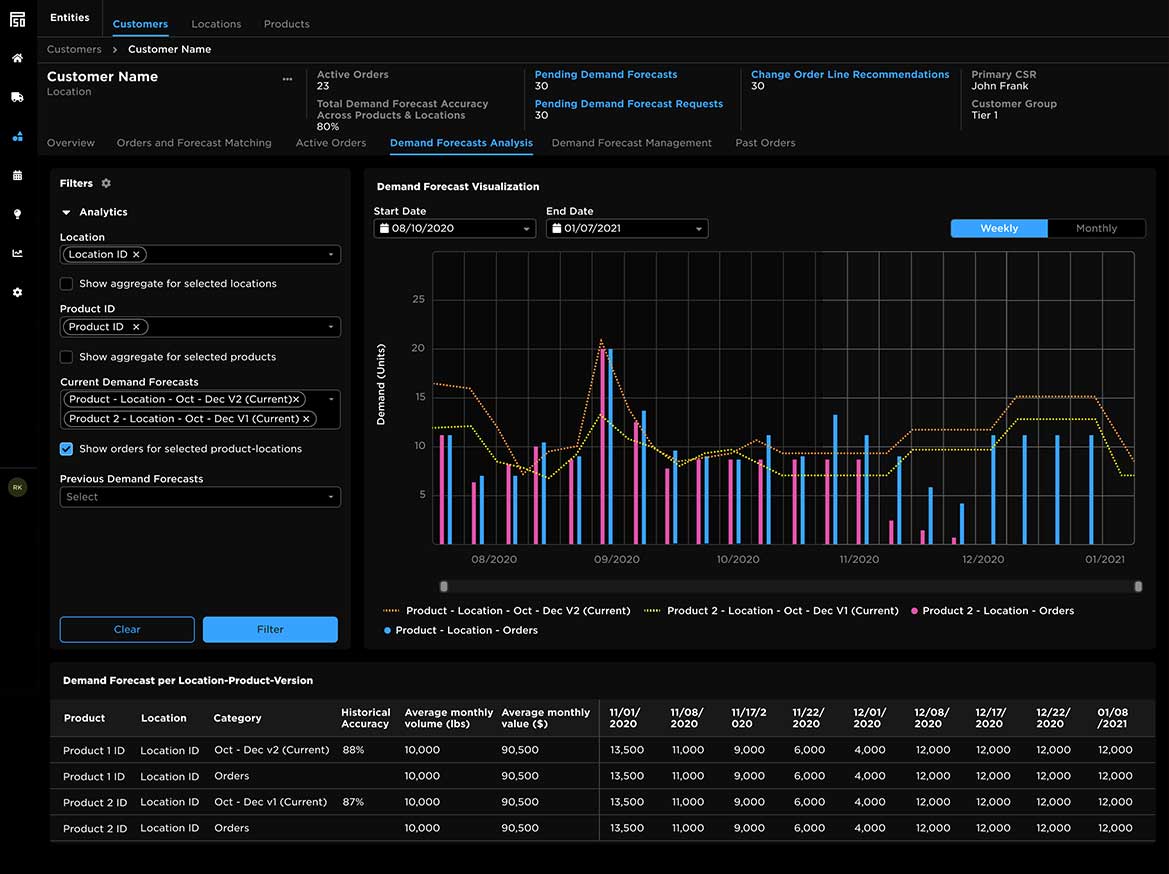

- C3 AI Demand Forecasting

- C3 AI Energy Management

- C3 AI ESG

- C3 AI Health

- C3 AI Intelligence Analysis

- C3 AI Inventory Optimization

- C3 AI Process Optimization

- C3 AI Production Schedule Optimization

- C3 AI Property Appraisal

- C3 AI Readiness

- C3 AI Reliability

- C3 AI Smart Lending

- C3 AI Sourcing Optimization

- C3 AI Supply Network Risk

- C3 AI Turnaround Optimization

- C3 Generative AI Constituent Services

- C3 Law Enforcement

- C3 Agentic AI Platform

- C3 Generative AI

- Get Started with a C3 AI Pilot

- Industries

- Customers

- Events

- Resources

- Generative AI for Business

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can the Generative AI Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- What Is Enterprise AI?

- Machine Learning

- Introduction

- What is Machine Learning?

- Tuning a Machine Learning Model

- Evaluating Model Performance

- Runtimes and Compute Requirements

- Selecting the Right AI/ML Problems

- Best Practices in Prototyping

- Best Practices in Ongoing Operations

- Building a Strong Team

- About the Author

- References

- Download eBook

- All Resources

- Publications

- Customer Viewpoints

- Blog

- Glossary

- Developer Portal

- Generative AI for Business

- News

- Company

- Contact Us

Meet production goals, maximize utilization, and reduce costs

Key Capabilities

Interpretable AI Insights

Interpretable AI Insights

- Leverage an interpretability framework that provides visibility into major cost drivers and production bottlenecks

- Review AI-generated alerts with robust evidence packages and explainability

Optimal manufacturing and distribution schedules

Optimal manufacturing and distribution schedules

- Account for constraints that change over time

- Provide visibility into major cost drivers and production bottlenecks

- Create a single unified view of the manufacturing and distribution operations

AI-based change order predictions

AI-based change order predictions

- Predict and plan for change orders using AI techniques that predict likelihood of change

- Model each order-line characteristic (e.g., historical changes in orders and order-lines by customer, customer purchasing behavior) and its evolution over time

Elastic solver for scheduling

Elastic solver for scheduling

- Schedule manufacturing or logistics operation using an elastic solver

- Minimize production costs, inventory costs, and staffing costs

- Maximize high-margin product throughput by deploying resources at the right time, in the right order, at the right capacity

Scenario analyses

Scenario analyses

- Analyze what-if scenarios to assess the impact of planning, production, and distribution modifications on throughput, cost, and profit

- Configure alerts and recommendations specific to customer, products, orders, and facilities

- Tune the machine learning models to accommodate operations complexity

Enterprise-wide collaboration

Enterprise-wide collaboration

- Align sales, marketing, planning, and manufacturing activities behind one planning and scheduling suite

- Use bidirectional integration with existing systems of record

Application Scope

C3 AI Production Schedule Optimization can be deployed for any customer demand scope and across all major types of manufacturing and distribution operations.

Customer Demand

Global, regional, local

Customer-product-facility granularity

Daily, weekly, monthly time horizon

Production Processes

Process manufacturing

Discrete manufacturing

Make-to-stock

Make-to-order

Assemble-to-stock

Assemble-to-order

Distribution Processes

Truck, ship, railcar scheduling

Refinery to terminals

Facility to distribution centers

Industries

Industrial Manufacturing

Oil and Gas

Transportation

Freight Industry

Healthcare

Benefits for Application Users

Production Scheduler

Deliver accurate production requirements to schedule engineers based on AI-based production schedules.

Scheduling Engineer

Generate optimal process schedules, meet customer demand, and minimize waste while accounting for all operational constraints.

Production Manager

Set and meet realistic production facility objectives for maximum throughput and minimum cost.

Data and Architecture