Improving U.S. Air Force Mission Capability with AI

The U.S. Air Force has designated the Predictive Analytics and Decision Assistant (PANDA), co-developed with C3 AI, as the System of Record for predictive maintenance to improve fleet availability and reduce lifecycle costs.

Download Case StudyIntroduction

The U.S. Air Force (USAF) operates the world’s largest, most technologically advanced, and powerful air fleet in the world. Maintaining and operating such a diverse fleet is mission-critical, complex, and costs tens of billions of dollars annually.

Yet, at any given time, many of these aircraft are not ready to fly.

A U.S. Government Accountability Office (GAO) report from 2022 found that aircraft mission-capable goals are usually not met. Of the 49 types of military aircraft the GAO studied, only four met their annual mission readiness goals for most of the years from FY 2011 through FY 2021. More than half of the aircraft types studied, 26 in all, did not meet their annual mission-capable goals in any fiscal year.

This is where AI can help. The mission of the Rapid Sustainment Office (RSO) is to optimize warfighter readiness by exploiting technologies to revolutionize sustainment operations. One of the key technology focus areas for the RSO is using artificial intelligence and machine learning to identify issues before they occur – such as identifying aircraft systems and components at risk of failure.

Collaboration

The RSO has set up the Condition-Based Maintenance Plus (CBM+) program office for applying artificial intelligence and machine learning to optimize fleet maintenance, increase aircraft availability, and minimize downtime. C3 AI has been an integral part of CBM+ since 2020 to:

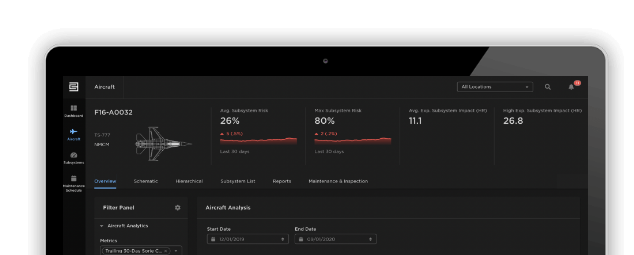

- Develop the Predictive Analytics and Decision Assistant (PANDA) toolkit, powered by the C3 AI Platform and C3 AI Readiness application and hosted on Air Force Cloud One powered by AWS GovCloud, to identify aircraft systems and components at risk of failure, provide evidence for the need for proactive maintenance, and ensure availability of the right parts at the right place at the right time for maintenance.

- Meet all security requirements for the PANDA application to achieve Authorization to Operate enabling the application to be accessible to any user with a verified “need-to-know” and a DoD-issued Common Access Card (CAC).

- Scale the PANDA toolkit to monitor 3,110 aircraft across 16 aircraft platforms. The PANDA toolkit currently has 8 applications for 800+ active users.

- Highlight and scale the power of using sensor telemetry data to actively detect signs of degradation within an aircraft system or component.

C3 AI Readiness

C3 AI Readiness

With PANDA and the CBM+ program office, the RSO and C3 AI have created a platform that helps:

Aircraft Maintenance Engineers use AI-based alerts to identify and prioritize part replacements.

Supply Chain analysts ensure adequate supply of parts based on the replacement forecasts generated by AI algorithms.

Maintainers validate AI-based recommendations, reducing time and cost of maintenance.

Leadership plan and deploy operationally ready assets.

“PANDA, co-developed with C3 AI, being designated as the system of record for Condition Based Monitoring Plus is a monumental achievement for the Rapid Sustainment Office and Air Force CBM+ enterprise.”

Chris Damani

RSO CBM+ Program Office Chief, U.S. Air Force

RSO Timeline of Events

PANDA 1.0 Released with eRCM Forecast and Metrics Dashboard

PANDA Deployed to Cloud 1 Test

PANDA 2.0 Release with eRCM Analyst Workflow

PANDA 3.0 Released with Long Range Supply Forecast and User Management

1st eRCM forecast published

PANDA 3.1 Released with new Home Page and Training

Received Authorization to Operate

PANDA 3.2 Released with Supply Depot Dashboard to centralize supply data in one application for effective management of CBM+ components

PANDA 4.0 Released with SBA module for responding to sensor alerts, Master Data Management for data cleansing, and fielding of SBA for B-1B

PANDA 4.1 Released with enhanced SBA case management to manage alerts

PANDA designation as USAF Predicative Maintenance System of Record

PANDA exceeds 800 active users

PANDA 4.2 Released with SBA go-live for the C-5 platform

PANDA 4.3 Released with SBA go-live for the KC-135 platform and fielding a new PANDA application, Predictive Fleet Health, to improve risk-based operational fleet decisions

PANDA Capabilities

Setting Component Useful Life Thresholds

Much of aircraft downtime is due to unexpected breakdowns of a system, subsystem, or component. If a replacement part is not immediately available, the aircraft could end up temporarily grounded. With the PANDA toolkit, part failures can be anticipated, so repairs are done proactively.

PANDA unifies data from multiple maintenance information systems to access historical data on maintenance actions and equipment status reports at component-level granularity. Much of this data is unstructured, and PANDA uses natural language processing AI/ML models to interpret the freeform maintenance text narratives to determine what maintenance actions were performed and determine time-to-failure for those components. This is used in the eRCM (enhanced Reliability Centered Maintenance) application to define the useful life threshold for each aircraft part i.e., the number of aircraft flying hours after which a component in service should be replaced. Armed with this intelligence, maintenance crews can maximize the use of a component over its useful life yet replace it before it fails

Providing Visibility of Supply Stock

Supply Chain analysts use the Supply Depot dashboard to easily track components by their unique identifiers such as national stock number and part number. Using this application, analysts can track the sites where components are located and identify managers to follow up with regarding questions about supply and repair details.

Prioritizing Maintenance Requirements

Maintenance planning teams rely on the PANDA toolkit to identify and prioritize part replacements during planned maintenance events. PANDA generates detailed CBM+ forecasts of remaining life for critical parts on active service aircraft. This helps maintenance planners understand which parts and on what aircraft need the most attention during maintenance events. PANDA ensures that maintenance analysts are always on top of the most urgent repairs with continuously updated watchlist items, reminders, and alerts.

Generating Long-Range Supply Forecasts

Maintenance managers also need parts available to replace components that have hit their useful life thresholds. PANDA helps supply chain analysts compare their planned parts inventory with the parts requirements generated by the CBM+ forecasts. Based on historical demand, useful life analysis, forecasted failure windows, and projected flight hours for the aircraft, supply chain analysts can create 5-year plans for component requirements. This ensures that the USAF carries the optimal number of parts to keep planes mission-capable.

Detecting Failure of Components

While historical maintenance data has proven useful in proactive maintenance and parts planning, sensor data allows planners and analysts to gain further insights into the current health of an aircraft. The RSO, working with C3 AI, has proven the value of sensor-based machine learning algorithms for select failure models of three aircraft platforms – the B-1B, C-5 and the KC-135. Using this approach, the RSO and C3 AI team have shown significant value in near real-time detection of degradation, unlocking previously hidden insights. The B-1B and C-5 have created a foundation for the rollout of sensor-based AI/ML algorithms to all USAF aircraft platforms, improving timely maintenance and mission capability rates.

Ensuring Secure Access

The PANDA toolkit is hosted within the Air Force’s Cloud One IL-5 (DoD Impact Level 5) environment allowing the application and its data to remain within government control. Moreover, the applications are web-based and Common Access Card (CAC) authenticated, ensuring reliable, secure, and yet convenient access to all of PANDA’s users.

The Future of Aircraft Maintenance for the U.S. Air Force

The RSO is committed to a vision of using technology and innovative solutions to improve mission readiness of the U.S. Air Force. While strong progress has been made in the creation and scaling of the PANDA toolkit, RSO has its eye on future capabilities including the use of more data sources for improved AI/ML model accuracy, generating Tail and Fleet Health assessments, and arming maintainers with actionable recommendations to implement repairs. As technology advances, the RSO will continue to play a pivotal role in ensuring the defense preparedness of the United States of America and its allies.

Get in Touch

Learn how C3 AI Readiness can help your organization in a personalized demo.