- AI Software

- C3 AI Applications

- C3 AI Applications Overview

- C3 AI Anti-Money Laundering

- C3 AI Cash Management

- C3 AI Contested Logistics

- C3 AI CRM

- C3 AI Decision Advantage

- C3 AI Demand Forecasting

- C3 AI Energy Management

- C3 AI ESG

- C3 AI Health

- C3 AI Intelligence Analysis

- C3 AI Inventory Optimization

- C3 AI Process Optimization

- C3 AI Production Schedule Optimization

- C3 AI Property Appraisal

- C3 AI Readiness

- C3 AI Reliability

- C3 AI Smart Lending

- C3 AI Sourcing Optimization

- C3 AI Supply Network Risk

- C3 AI Turnaround Optimization

- C3 Generative AI Constituent Services

- C3 Law Enforcement

- C3 Agentic AI Platform

- C3 Generative AI

- Get Started with a C3 AI Pilot

- Industries

- Customers

- Events

- Resources

- Generative AI for Business

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can the Generative AI Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- What Is Enterprise AI?

- Machine Learning

- Introduction

- What is Machine Learning?

- Tuning a Machine Learning Model

- Evaluating Model Performance

- Runtimes and Compute Requirements

- Selecting the Right AI/ML Problems

- Best Practices in Prototyping

- Best Practices in Ongoing Operations

- Building a Strong Team

- About the Author

- References

- Download eBook

- All Resources

- Publications

- Customer Viewpoints

- Blog

- Glossary

- Developer Portal

- Generative AI for Business

- News

- Company

- Contact Us

Improve Execution Efficiency and Reduce Turnaround Durations

Key Capabilities

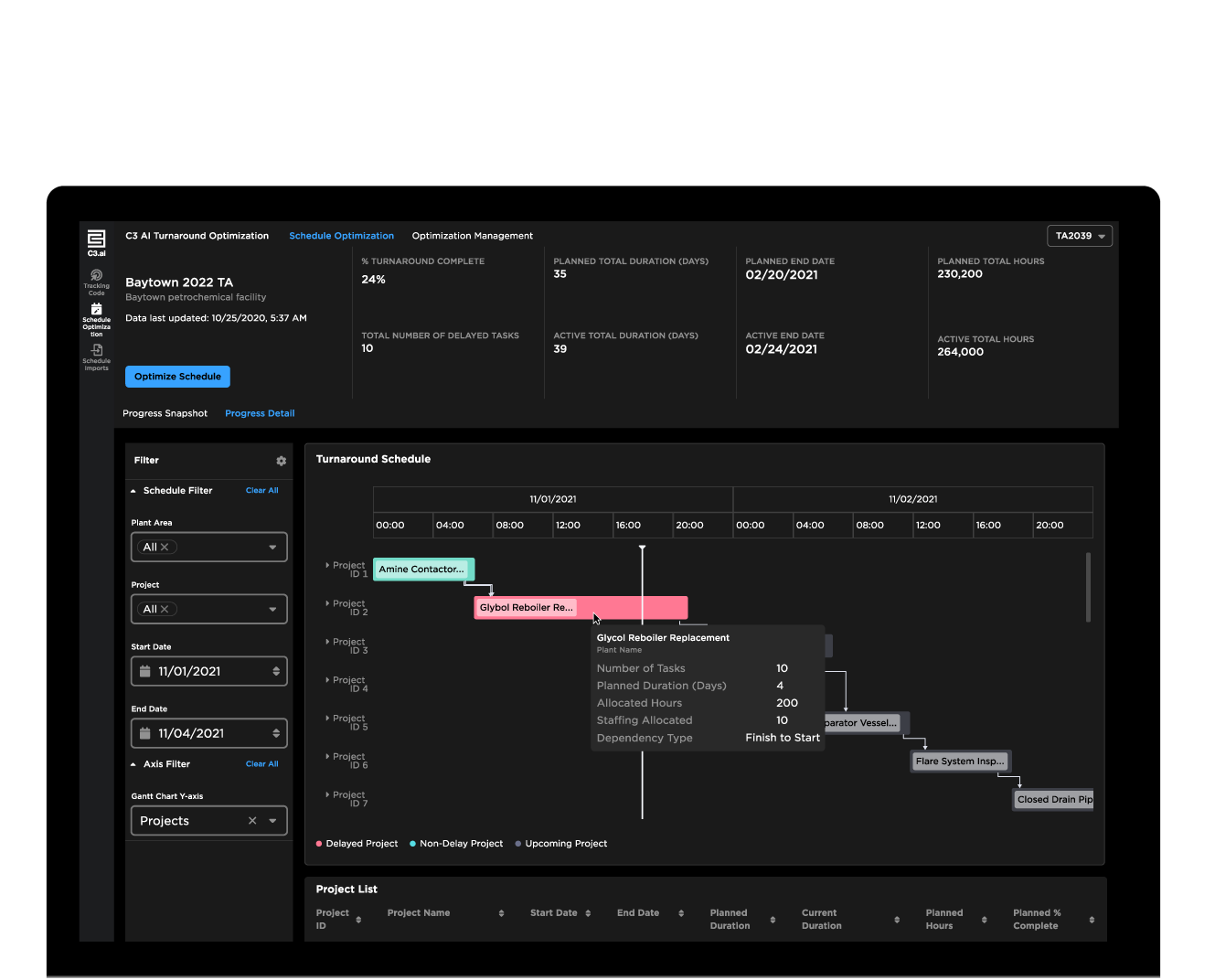

Near-real time turnaround progress monitoring

Near-real time turnaround progress monitoring

- Automatically ingest data from existing project management software as execution progress is reported from the field

- Visualize real-time progress via S-curves, rundown curves, and granular Gantt chart and grid views

Performance benchmarking versus historical events

Performance benchmarking versus historical events

- Track milestone completion across priority equipment categories to monitor high-level turnaround progress

- Select multiple historical turnarounds to compare performance and benchmark progress

- Receive targeted alerts if progress falls behind comparable historical turnarounds for specific equipment categories or milestones

AI-based delay risk predictions

AI-based delay risk predictions

- Receive a prioritized list of alerts identifying delayed activities and their estimated impact on the overall turnaround duration

- Analyze the impact of each delay on the overall turnaround schedule, including cascading impacts on dependent activities

- Review and implement AI-recommended mitigation strategies

AI-driven schedule optimization

AI-driven schedule optimization

- Apply cutting-edge AI techniques to analyze complex turnaround schedules including thousands of variables to identify and eliminate delays

- Define optimization parameters and constraints including shift structures and available resources such as workers by craft or qualification.

Comprehensive delay mitigation scenario analysis

Comprehensive delay mitigation scenario analysis

- Review and assess recommended actions to eliminate delays by re-allocating resources to critical activities

- Explore the details of recommended resource allocations, make adjustments, and generate re-optimized schedules

Bi-directional integrations to existing systems

Bi-directional integrations to existing systems

- Directly export the optimized schedule into existing project management and/or work management systems

- Predict asset reliability and discovery risks via native integrations with C3 AI Reliability

Scope

C3 AI Turnaround Optimization can be deployed across a wide range of industries and facility types.

Turnaround activities

Facility handover

Equipment disassembly / reassembly

Inspections

Repairs / Refurbishment

Craft work (scaffolding, welding, insulation, etc.)

Equipment Cleaning

Capital Projects

Facilities

Upstream oil and gas production

Refineries

Chemical

Other processing plants

Submarines

Shipping vessels

Industries

Oil & Gas

Petrochemicals

Specialty chemicals

Pharmaceuticals

Biotechnology

Marine & shipping

Benefits for Turnaround Professionals

Turnaround Manager

Monitor turnaround progress, benchmark against historical performance, identify critical execution risks.

Turnaround Scheduler

Receive progress updates, identify delays, review AI-driven mitigation options, generate updated work plans to eliminate delays.

Work Coordinator

Lead work execution in the field, report progress, communicate delays, execute updated work plans.

Data Sources